Introduction

In today's fast-paced world, high-quality plastic materials are essential for a wide range of industries. From automotive to consumer goods, the demand for reliable injection molded plastic parts continues to grow. At Baoyuan, we pride ourselves on being a leading source for expertise in injection molding, providing innovative solutions for all your plastic manufacturing needs. When choosing plastic materials, it's crucial to consider factors such as durability, flexibility, and cost-effectiveness.

The Importance of High-Quality Plastic Materials

The importance of high-quality plastic materials cannot be overstated in today's manufacturing landscape. Whether it's for automotive components, electronic devices, or medical equipment, the performance and reliability of injection molded plastic parts play a critical role in product quality and longevity. At Baoyuan, we understand the significance of using top-grade materials to ensure that our customers receive products that meet their exact specifications and performance requirements.

Baoyuan: Your Source for Expertise in Injection Molding

As a trusted industry leader in injection molding, Baoyuan is dedicated to delivering top-notch solutions for all your plastic manufacturing needs. With our extensive experience and state-of-the-art facilities, we have the capability to produce a wide variety of injection molded plastic products that meet the highest standards of quality and precision. Whether you need custom-designed auto parts or innovative packaging solutions, Baoyuan has the expertise and resources to bring your vision to life.

Key Considerations When Choosing Plastic Materials

When it comes to choosing the right plastic materials for your project, there are several key considerations to keep in mind. Factors such as material properties, design requirements, production volume, and cost-effectiveness all play a crucial role in determining the most suitable options for injection molded plastic parts. At Baoyuan, we work closely with our clients to understand their specific needs and provide expert guidance on selecting the most appropriate materials for their applications.

Understanding the Types of Injection Molded Plastic

When it comes to injection molded plastic, it's essential to understand the difference between thermoplastics and thermosets. Thermoplastics can be melted and re-molded multiple times, making them versatile for various applications. On the other hand, thermosets undergo a chemical change during molding, resulting in a rigid and durable final product.

Thermoplastics vs. Thermosets

Thermoplastics, such as polyethylene and polypropylene, are commonly used for injection molded plastic parts due to their flexibility and recyclability. They are ideal for products that require repeated heating and shaping processes. On the other hand, thermosets like epoxy and phenolic resins are preferred for applications that demand high heat resistance and dimensional stability.

Thermoplastics offer a wide range of benefits for injection molded plastic parts, including their ability to be easily melted and reshaped multiple times without undergoing significant chemical changes. This makes them perfect for products that require intricate designs or frequent modifications. Additionally, their recyclability makes them an environmentally friendly choice for manufacturers and consumers alike. On the other hand, thermosets provide exceptional heat resistance and dimensional stability, making them the top choice for applications such as electronic components or automotive parts that are exposed to high temperatures and harsh conditions.

Common Applications for Injection Molded Plastic Parts

Injection molded plastic parts are widely used in automotive components, consumer electronics, medical devices, and household appliances. From intricate gears to complex housings, these parts offer design flexibility, cost-effectiveness, and high production rates.

Additionally, injection molded plastic parts are often used in the manufacturing of sporting goods, such as helmets, protective gear, and equipment components. The durability and lightweight nature of these parts make them ideal for use in products designed for athletic activities. This allows manufacturers to create high-quality, long-lasting sporting goods that can withstand the rigors of regular use.

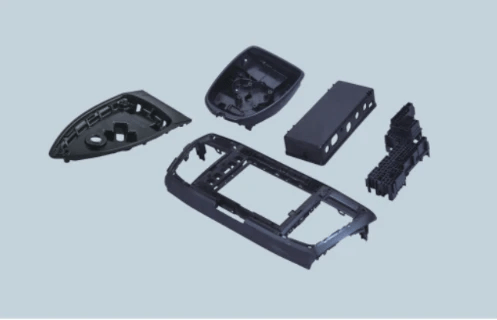

Baoyuan's Extensive Range of Injection Molded Plastic Products

Baoyuan offers an extensive range of injection molded plastic products tailored to meet diverse industry needs. From custom-designed auto parts to precision medical device components, Baoyuan's expertise in injection molding ensures top-notch quality and performance.

Baoyuan's commitment to quality and innovation sets them apart in the injection molding industry. With a focus on using advanced materials and cutting-edge technology, they are able to produce plastic products that exceed industry standards. Whether it's creating durable and lightweight components for aerospace applications or developing intricate parts for consumer electronics, Baoyuan's dedication to excellence shines through in every project.

Finding Reliable Injection Molded Plastic Manufacturers

Quality assurance is crucial in plastic manufacturing to ensure the durability and performance of injection molded plastic parts. Choosing a manufacturer that upholds strict quality standards is essential for producing high-quality products that meet industry requirements and customer expectations.

Baoyuan's unwavering commitment to quality and precision sets us apart as a trusted injection molded plastic manufacturer. Our state-of-the-art facilities, advanced technology, and skilled workforce enable us to deliver products with exceptional accuracy, consistency, and reliability.

Experience plays a pivotal role in selecting an injection molded plastic manufacturer. With Baoyuan's extensive experience in the industry, we have honed our expertise in understanding the unique needs of various sectors, offering tailored solutions that meet specific requirements and exceed performance standards.

Designing Injection Molded Plastic Parts

When it comes to injection molded plastic parts, the design plays a crucial role in determining the quality of the final product. Factors such as wall thickness, rib design, and gate placement all impact the strength and durability of the part. At Baoyuan, we understand the importance of thoughtful design in creating high-quality injection molded plastic parts that meet your specific requirements.

The Impact of Design on Injection Molded Plastic Quality

The design of injection molded plastic parts directly affects their overall quality and performance. Proper design considerations can minimize defects such as warping, sink marks, and voids, ensuring that the final product meets industry standards for strength and precision. Baoyuan's team of experienced engineers works closely with clients to optimize part designs for maximum functionality and durability.

Proper design considerations also play a crucial role in minimizing material waste and production costs. By optimizing part designs, Baoyuan's engineers can reduce the amount of raw materials needed for each injection molded plastic part, ultimately leading to cost savings for clients. This focus on efficient design not only benefits the bottom line but also contributes to sustainable manufacturing practices, aligning with modern environmental standards and regulations.

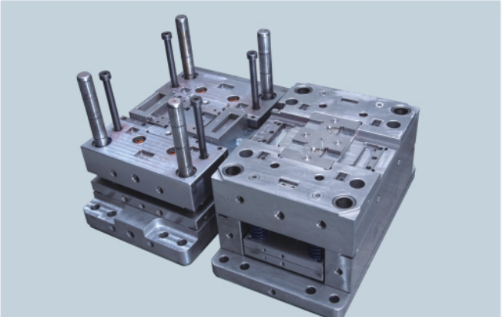

Baoyuan's Software Expertise for Mold Design

At Baoyuan, we leverage advanced software tools to create precise mold designs for injection molded plastic parts. Our expertise in CAD/CAM software allows us to develop intricate mold designs that result in accurate and consistent part production. By utilizing cutting-edge technology, we can ensure that every detail of your custom injection molded plastic parts is meticulously planned and executed.

Our team of skilled engineers and designers are well-versed in the latest software tools, allowing us to offer a wide range of customization options for injection molded plastic auto parts. Whether you need intricate detailing, specific material requirements, or unique design features, our CAD/CAM expertise enables us to bring your vision to life with precision and accuracy. With our advanced software capabilities, we can tailor mold designs to meet the exact specifications of your custom auto parts, ensuring optimal performance and quality.

Customization Options for Injection Molded Plastic Auto Parts

For automotive applications, customization is key when it comes to injection molded plastic parts. Baoyuan offers a wide range of customization options for auto parts, including material selection, color choices, and surface finishes. Whether you need interior trim components or under-the-hood parts, our team can tailor the design and production process to meet your exact specifications.

Remember: The quality of injection molded plastic products begins with thoughtful design and expert mold engineering. With Baoyuan as your partner in manufacturing customized plastic components, you can trust that every detail will be carefully considered to deliver exceptional results.

Applications of Injection Molded Plastic in Packaging

Advantages of Injection Molded Plastic Packaging

Injection molded plastic packaging offers numerous advantages, including durability, lightweight construction, and cost-effectiveness. These qualities make it an ideal choice for protecting and showcasing a wide range of products, from food and beverages to electronics and personal care items.

Injection molded plastic packaging is also highly customizable, allowing for intricate designs and unique shapes to be created with ease. This level of customization enables brands to differentiate their products on the shelf and create a memorable experience for consumers. Additionally, the versatility of injection molded plastic packaging means it can be used for a wide range of product types, from irregularly shaped items to those requiring specific barrier properties.

Baoyuan's Expertise in Single-Color and Double-Color Products

Baoyuan is a leader in the production of single-color and double-color injection molded plastic packaging. With advanced technology and a focus on precision, they are able to create packaging solutions that meet the specific needs of their clients while maintaining high standards of quality and aesthetic appeal.

With a dedicated team of experienced engineers and designers, Baoyuan is able to stay at the forefront of innovation in injection molded plastic packaging. They are constantly researching and developing new techniques and materials to improve the functionality and visual appeal of their products. This commitment to innovation ensures that Baoyuan's packaging solutions are always ahead of the curve, meeting the evolving needs of their clients in various industries.

Innovations in Injection Molded Plastic Packaging

Innovations in injection molded plastic packaging have led to the development of new designs and functionalities that enhance product visibility, shelf appeal, and sustainability. Baoyuan's commitment to staying at the forefront of these innovations ensures that their clients have access to cutting-edge packaging solutions that set their products apart.

In addition to enhancing product visibility and shelf appeal, injection molded plastic packaging innovations also focus on improving sustainability. Baoyuan's dedication to staying ahead of these advancements means that their clients can benefit from eco-friendly packaging solutions that reduce environmental impact without compromising on quality or performance. By embracing sustainable materials and production processes, Baoyuan is able to offer packaging options that align with the growing consumer demand for environmentally responsible products.

Ensuring Quality in Injection Molded Plastic Products

Baoyuan's Skilled Technical Personnel

At Baoyuan, our skilled technical personnel are experts in the field of injection molding, ensuring that every product meets the highest standards of quality and precision. With years of experience and a deep understanding of injection molded plastic, our team is dedicated to delivering top-notch results for all our clients.

Quality Control Measures in Injection Molding

Quality control is a top priority at Baoyuan, and we implement rigorous measures throughout the injection molding process to ensure that each part meets our strict quality standards. From material selection to final inspection, we take every step necessary to guarantee the durability and reliability of our injection molded plastic products.

Baoyuan's Proficiency in Mold Opening and Production Techniques

Our proficiency in mold opening and production techniques sets us apart as a leader in the industry. With state-of-the-art equipment and cutting-edge technology, we are able to produce high-quality injection molded plastic parts with exceptional precision and efficiency, meeting the unique needs of each client.

Conclusion

In conclusion, when it comes to choosing plastic materials for your projects, it's crucial to make informed decisions based on the specific requirements of your application. Baoyuan is your trusted partner in injection molding solutions, offering expertise in designing and manufacturing high-quality injection molded plastic parts. With a focus on precision and innovation, Baoyuan is leading the way in the future of high-quality injection molded plastic products.

Making Informed Decisions When Choosing Plastic Materials

When selecting plastic materials for your projects, it's essential to consider factors such as durability, flexibility, and cost-effectiveness. By understanding the most common injection molded plastic options available, you can make informed decisions that align with your project's needs. Whether it's for automotive applications or packaging solutions, choosing the right injection molded plastic is key to achieving optimal results.

Baoyuan: Your Trusted Partner in Injection Molding Solutions

Baoyuan stands out as a reliable manufacturer of injection molded plastic products, offering a wide range of customization options for auto parts and packaging solutions. With a commitment to quality assurance and precision manufacturing, Baoyuan is dedicated to delivering exceptional results that meet the highest standards of excellence.

The Future of High-Quality Injection Molded Plastic Products

As technology continues to advance, the future of high-quality injection molded plastic products looks promising with ongoing innovations in design and manufacturing techniques. Baoyuan remains at the forefront of this evolution, leveraging skilled technical personnel and cutting-edge quality control measures to ensure that their injection molded plastic products continue to meet and exceed industry standards.