Introduction

When it comes to automotive plastic injection molding, the industry is dominated by a select group of top players who have set the standard for quality and innovation. These injection moulding automotive companies have revolutionized the production of automotive plastic parts, making significant contributions to the advancement of the industry as a whole.

Top Automotive Injection Moulding Manufacturers

Among the top automotive plastic injection molding companies, there are key players that stand out for their expertise and commitment to excellence. These manufacturers have established themselves as leaders in the field, driving progress and setting new benchmarks for quality and efficiency in injection moulding automotive.

Key Players in the Injection Moulding Automotive Industry

The injection moulding automotive industry is shaped by key players who have made significant strides in developing cutting-edge technologies and innovative solutions for automotive plastic manufacturers. These companies have demonstrated a deep understanding of the unique challenges and demands of automotive plastic injection molding, positioning themselves as indispensable partners for OEMs and Tier 1 suppliers.

Leading Automotive Injection Moulding Companies

As leading automotive plastic parts manufacturers, these companies have not only mastered the art of precision molding but also embraced sustainable practices to minimize environmental impact. Their unwavering dedication to delivering high-quality products has solidified their position as leaders in the global automotive plastic manufacturing landscape.

Baoyuan: A Pioneer in Automotive Injection Moulding

Baoyuan has solidified its position as one of the top injection moulding automotive companies, with a proven track record of excellence in producing high-quality automotive plastic parts. Their expertise in automotive plastic injection molding is unmatched, making them a go-to choice for leading automotive manufacturers around the world.

Baoyuan's Expertise in Injection Moulding for Automotive Industry

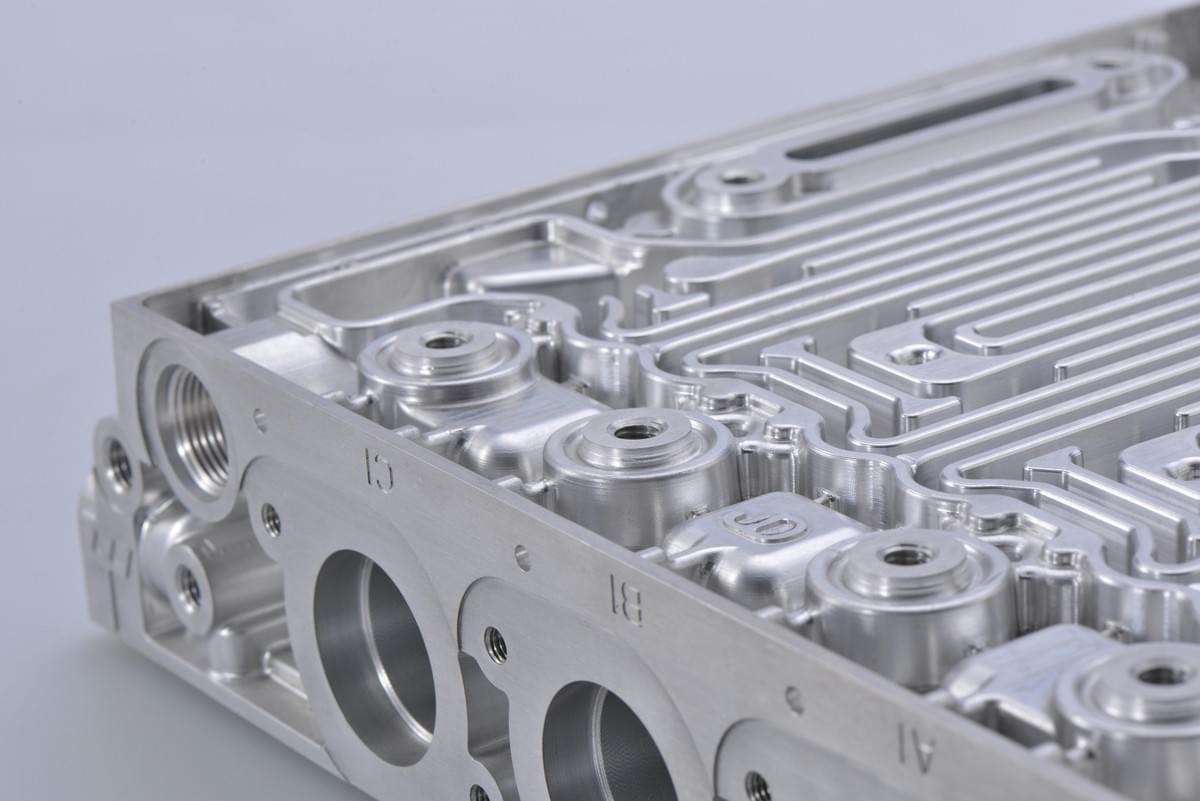

Baoyuan's commitment to innovation and precision has made them a standout among automotive plastic injection molding companies. Their deep understanding of the unique requirements of the automotive industry allows them to consistently deliver top-notch plastic parts that meet and exceed industry standards. In addition, Baoyuan utilizes advanced software for mold design and injection molding, ensuring the highest level of accuracy and efficiency in their manufacturing process. This cutting-edge technology enables them to produce complex automotive components with intricate designs and tight tolerances, setting them apart as a leader in the field.

Baoyuan's Advanced Software for Mold Design and Injection Moulding

Utilizing cutting-edge technology, Baoyuan has developed advanced software for mold design and injection moulding that sets them apart from other automotive plastic manufacturers. This enables them to create intricate designs with utmost accuracy, ensuring that every product meets the stringent demands of the automotive sector.

Additionally, Baoyuan's proficiency in single-color and double-color plastic products further demonstrates their expertise in meeting the diverse needs of the automotive industry. With their advanced software, they are able to seamlessly transition between different molds and materials, ensuring a high level of precision and consistency in their production processes. This versatility allows them to cater to a wide range of design requirements, making them a preferred choice for automotive plastic manufacturing.

Baoyuan's Proficiency in Single-Color and Double-Color Plastic Products

As experts in injectionmoulding automotive, Baoyuan boasts exceptional proficiency in manufacturing both single-color and double-color plastic products for the automotive industry. Their ability to produce diverse components with precision and consistency makes them a preferred choice for leading automobile manufacturers worldwide.

With a keen eye for detail and a commitment to excellence, Baoyuan consistently delivers high-quality single-color and double-color plastic products that meet the stringent requirements of the automotive industry. Their state-of-the-art manufacturing processes and advanced technology enable them to create durable and reliable components that contribute to the overall performance and safety of vehicles. As a result, Baoyuan has earned a reputation for being a trusted partner in the automotive supply chain, known for their ability to meet tight deadlines without compromising on quality.

KAI Group: Innovations in Automotive Injection Moulding

KAI Group is at the forefront of cutting-edge technologies for automotive injection moulding, utilizing state-of-the-art machinery and advanced materials to produce high-quality automotive plastic parts. Their commitment to innovation and precision has positioned them as one of the leading automotive plastic injection molding companies in the industry.

KAI Group's Cutting-Edge Technologies for Automotive Injection Moulding

KAI Group leverages the latest advancements in injection moulding technology to deliver superior automotive plastic parts that meet the stringent requirements of the automotive industry. Their use of innovative processes and materials ensures durability, strength, and precision in every component they manufacture, setting them apart as a top choice for automotive plastic manufacturers.

KAI Group's Commitment to Quality Assurance in Injection Moulding

With a relentless focus on quality assurance, KAI Group implements rigorous testing and inspection protocols throughout the injection moulding process to guarantee that each automotive plastic part meets exact specifications. This unwavering dedication to quality has earned them a reputation as a trusted partner for automotive plastic injection molding.

KAI Group's Impact on the Automotive Injection Moulding Industry

As a trailblazer in automotive injection moulding, KAI Group's innovative approaches and unwavering commitment to excellence have significantly impacted the industry, driving progress and setting new standards for quality and performance. Their contributions have solidified their position as a key player in shaping the future of injection moulding automotive companies.

Moldman: Revolutionizing Automotive Injection Moulding

Moldman is at the forefront of revolutionizing automotive plastic injection molding with its innovative approaches and cutting-edge technologies. The company's commitment to pushing the boundaries of traditional injection moulding processes has set it apart as a leader in the automotive plastic parts manufacturing industry.

Moldman's Innovative Approaches to Automotive Injection Moulding

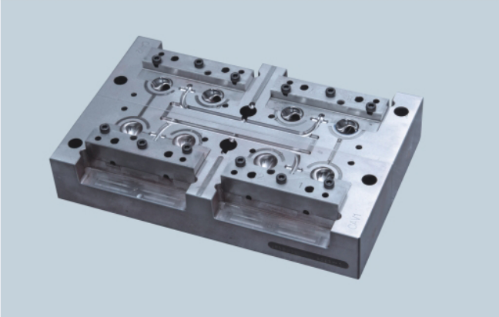

Moldman's innovative approaches to automotive plastic injection molding have redefined industry standards, offering unparalleled precision and efficiency in producing high-quality plastic parts for vehicles. With a focus on advanced mold design and state-of-the-art machinery, Moldman consistently delivers exceptional results that meet the evolving needs of the automotive industry.

Moldman's commitment to sustainable and eco-friendly injection molding practices sets them apart in the automotive industry. By utilizing cutting-edge technology and materials, Moldman reduces waste and energy consumption, contributing to a greener manufacturing process. This dedication to environmental responsibility not only benefits the planet but also aligns with the growing demand for eco-conscious products in the automotive market.

Moldman's Focus on Sustainable and Eco-Friendly Injection Moulding Practices

Moldman places a strong emphasis on sustainable and eco-friendly injection moulding practices, utilizing environmentally conscious materials and processes to minimize its carbon footprint. By prioritizing sustainability, the company not only contributes to a greener future but also provides automotive manufacturers with eco-friendly solutions for their plastic part production needs.

Moldman's commitment to sustainable and eco-friendly injection moulding practices extends beyond just the materials and processes used. The company also focuses on reducing waste and energy consumption in its manufacturing facilities, implementing innovative technologies to optimize production efficiency while minimizing environmental impact. By taking a holistic approach to sustainability, Moldman sets a new standard for eco-friendly plastic part production in the automotive industry.

Moldman's Contributions to the Advancement of Automotive Injection Moulding

Moldman has made significant contributions to the advancement of automotive injection moulding, driving innovation and pushing the boundaries of what is possible in plastic part manufacturing for vehicles. Through continuous research and development, as well as strategic partnerships with leading automotive companies, Moldman continues to shape the future of injection moulding in the automotive industry.

Moldman's commitment to innovation is evident in their cutting-edge technology and state-of-the-art manufacturing processes. By staying ahead of the curve and investing in the latest equipment and techniques, Moldman ensures that they are always at the forefront of automotive injection moulding. This dedication to staying current with industry trends allows them to consistently deliver high-quality, precision-engineered plastic parts for vehicles.

Sositar: Driving Progress in Automotive Injection Moulding

Sositar is at the forefront of shaping the future of automotive injection moulding, with a focus on innovation and cutting-edge technology. Their commitment to driving progress in the industry has solidified their position as one of the top automotive plastic injection molding companies. Sositar's dedication to pushing boundaries and exploring new possibilities has set them apart as a leader in automotive plastic injection molding.

Sositar's Role in Shaping the Future of Automotive Injection Moulding

Sositar plays a pivotal role in shaping the future of automotive injection moulding by constantly seeking out new methods and technologies to improve their processes. Their forward-thinking approach has positioned them as an industry trailblazer, driving innovation and setting new standards for automotive plastic parts manufacturers. With a keen eye on future trends, Sositar continues to push boundaries and redefine what is possible within the automotive plastic manufacturers landscape.

Sositar's Embrace of Technological Advancements in Injection Moulding

Sositar fully embraces technological advancements in injection moulding, utilizing state-of-the-art equipment and cutting-edge software to optimize their manufacturing processes. This commitment to staying ahead of the curve has allowed them to deliver high-quality products that meet and exceed industry standards for automotive plastic injection molding. By leveraging advanced technology, Sositar ensures that they remain at the forefront of innovation within the injection moulding automotive industry.

Sositar's Commitment to Meeting the Diverse Needs of the Automotive Industry

Sositar is dedicated to meeting the diverse needs of the automotive industry by offering a wide range of solutions tailored to specific requirements. As one of the leading injection moulding automotive companies, they understand that flexibility and adaptability are crucial in meeting ever-changing demands within the industry. By prioritizing customer needs and delivering customized solutions, Sositar continues to solidify its reputation as a trusted partner for all automotive plastic manufacturing needs.

LK Mould: Setting the Standard for Automotive Injection Moulding

When it comes to injection moulding automotive, LK Mould stands out as a leader in the industry. With decades of experience and a strong track record of success, LK Mould has established itself as one of the top automotive plastic injection molding companies in the market. Their expertise in producing high-quality automotive plastic parts is unparalleled, making them a go-to choice for manufacturers looking for precision and reliability.

LK Mould's Unparalleled Expertise in Automotive Injection Moulding

LK Mould's expertise in automotive plastic injection molding is evident in their ability to consistently deliver top-notch products that meet the strictest industry standards. Their deep understanding of the unique requirements of the automotive industry allows them to produce complex and intricate plastic parts with utmost precision and efficiency. As one of the leading automotive plastic manufacturers, LK Mould takes pride in its ability to provide innovative solutions that drive progress within the industry.

LK Mould's Dedication to Innovation and Precision in Injection Moulding

LK Mould's dedication to innovation and precision sets them apart from other injection moulding automotive companies. They continuously invest in cutting-edge technologies and state-of-the-art equipment to ensure that their manufacturing processes remain at the forefront of industry advancements. This commitment to innovation not only enhances their efficiency but also allows them to offer cost-effective solutions without compromising on quality, making them a preferred partner for automotive plastic injection molding needs.

LK Mould's Impact on the Global Automotive Injection Moulding Landscape

As a key player in the global automotive injection moulding landscape, LK Mould has made significant contributions towards shaping the future of the industry. Their unwavering commitment to excellence has earned them recognition as an influential force driving progress within the sector. With an extensive portfolio of successful projects and satisfied clients, LK Mould continues to set new standards for quality, reliability, and innovation in automotive plastic manufacturing.

Conclusion

When it comes to choosing the right automotive injection moulding partner, it's essential to consider factors such as expertise, innovation, and commitment to quality. With the rapid advancements in technology, the future of automotive injection moulding is poised for exciting developments and breakthroughs. As advanced technologies continue to shape the landscape of automotive injection moulding, companies must adapt and embrace these innovations to stay ahead in this competitive industry.

Choosing the Right Automotive Injection Moulding Partner

Selecting a reliable partner for automotive plastic injection molding is crucial for ensuring high-quality products and efficient production processes. Look for companies that have a proven track record in delivering innovative solutions and meeting the specific needs of the automotive industry. It's essential to collaborate with injection moulding automotive companies that prioritize precision, reliability, and customer satisfaction.

The Future of Automotive Injection Moulding

The future of automotive plastic injection molding is set to witness remarkable advancements driven by cutting-edge technologies such as 3D printing, automation, and sustainable materials. These innovations will revolutionize manufacturing processes, resulting in more cost-effective production methods and environmentally friendly practices. As the industry continues to evolve, staying abreast of these developments will be crucial for success.

The Impact of Advanced Technologies on Automotive Injection Moulding

Advanced technologies are reshaping the landscape of automotive plastic parts manufacturing by enabling greater efficiency, accuracy, and customization capabilities. From smart molding machines to digital twin simulations, these innovations are enhancing productivity while reducing waste and energy consumption. Embracing these advanced technologies will be pivotal in driving progress within the automotive injection moulding industry.