Introduction

In the ever-evolving landscape of manufacturing, **PVC injection molding** stands out as a versatile and efficient process that has gained significant traction across various industries. This technique involves injecting molten PVC into molds to create a wide array of products, from everyday items to specialized components. Understanding what PVC injection molding entails is crucial for anyone looking to leverage its advantages in production.

Understanding PVC Injection Molding

So, what is PVC injection molding? At its core, it’s a method where polyvinyl chloride (PVC) is heated until it becomes liquid and then injected into a mold under high pressure. This process not only allows for intricate designs but also ensures consistency in product quality, making it an attractive option for manufacturers.

Key Applications of PVC Molding

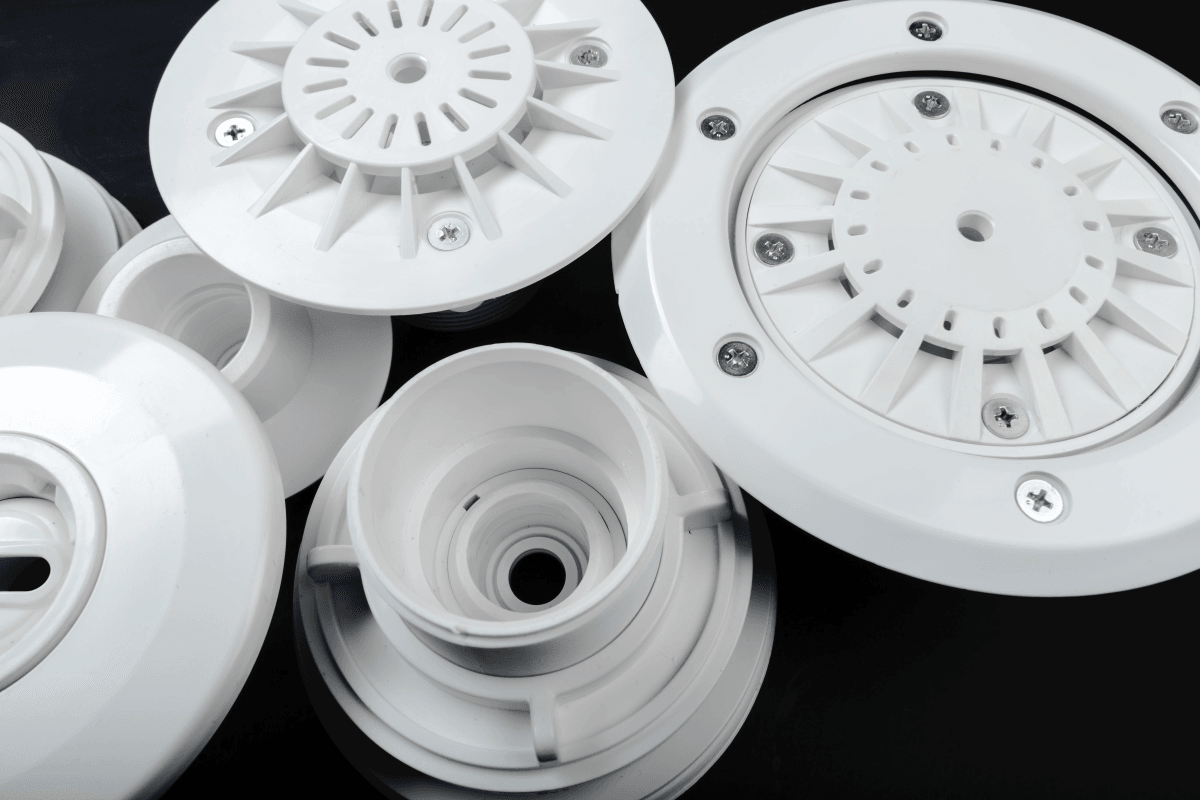

The applications of **PVC molding** are vast and varied; from consumer goods like containers and toys to essential automotive parts and construction materials, the possibilities are nearly endless. Industries have embraced this technology due to its adaptability, enabling the creation of both functional and aesthetic products with ease. With such versatility, it's no wonder that many companies are turning to PVC for their manufacturing needs.

The Benefits of Choosing PVC

Why choose PVC? The advantages of **PVC injection molding** are numerous: it offers cost-effectiveness due to lower material costs and shorter production times while maintaining durability against wear and environmental factors. Additionally, advancements in technology mean that manufacturers can produce high-quality products with reduced environmental impact—making it not just smart business but also a responsible choice.

What is PVC Injection Molding?

When diving into the world of manufacturing, one might stumble upon the term PVC injection molding. This method is a highly efficient process used to create various products from polyvinyl chloride (PVC) plastic. By understanding what PVC injection molding entails, one can appreciate its versatility and effectiveness in producing durable and high-quality items.

Definition and Process Overview

So, what is PVC injection molding? At its core, it’s a manufacturing technique where melted PVC material is injected into a mold to form specific shapes. The process begins with heating the PVC until it becomes pliable, then injecting it under high pressure into a mold cavity where it cools and solidifies into the desired form. This method allows for intricate designs and precise dimensions, making it a go-to choice for many industries.

Differences Between PVC and Other Molding Methods

When considering what makes PVC injection molding stand out, it's essential to compare it with other molding methods like thermoplastic or thermosetting processes. Unlike traditional methods that may require longer curing times or additional steps, PVC injection molding offers rapid production cycles and lower labor costs due to automation capabilities. Additionally, while some plastics may warp or degrade over time, the durability of PVC gives it an edge in longevity compared to materials such as polystyrene or polyethylene.

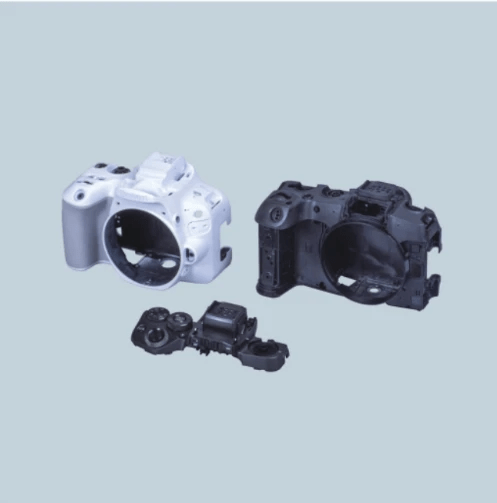

Common Uses in Various Industries

The versatility of what is PVC injection for can be seen across multiple sectors including consumer goods, automotive parts, and construction materials. In consumer goods, you might find everything from toys to household items made using this efficient method due to its ability to produce complex shapes at scale. In the automotive industry, components like dashboards and trims benefit from the strength of PVC while ensuring lightweight characteristics that enhance fuel efficiency.

What is PVC Molding?

PVC molding is a widely used manufacturing process that transforms polyvinyl chloride (PVC) resin into various shapes and products. This versatile technique, often referred to as PVC injection molding, allows for the production of complex geometries with high precision and efficiency. Understanding what PVC molding entails is crucial for industries looking to leverage its benefits in their applications.

The Fundamentals of PVC Molding

At its core, what is PVC molding? It involves heating PVC resin until it becomes pliable and then injecting it into a mold where it cools and solidifies into the desired shape. The process can be tailored to produce items ranging from simple components to intricate designs, making it an ideal choice for many industries. With the ability to create durable and lightweight products, this method stands out in the plastic manufacturing landscape.

The fundamentals of PVC injection molding also include considerations such as temperature control, mold design, and cycle time—each playing a pivotal role in determining the quality of the final product. Mastering these fundamentals ensures that manufacturers can consistently produce high-quality items that meet industry standards. Furthermore, understanding these elements helps businesses make informed decisions about their production processes.

Material Properties that Matter

When discussing what is PVC injection molding, it's essential to highlight the material properties that make PVC a popular choice among manufacturers. One significant advantage of using PVC is its excellent chemical resistance, which allows products made from this material to withstand harsh environments without deteriorating quickly. Additionally, PVC has good electrical insulation properties, making it suitable for various electronic applications.

Another critical property of PVC is its versatility; it can be formulated with additives that enhance its flexibility or rigidity based on specific needs. This adaptability means that manufacturers can tailor their products for particular applications while maintaining cost-effectiveness—a vital consideration in today's competitive market. Ultimately, understanding these material properties helps businesses maximize the advantages of using PVC in their projects.

Comparison with Other Plastic Materials

In comparing what is PVC molding with other plastic materials like polyethylene (PE) or polypropylene (PP), several distinctions emerge regarding performance and application suitability. While PE offers excellent flexibility and impact resistance, it lacks some chemical resistance characteristics found in PVC products—making them less ideal for certain industrial uses. On the other hand, PP may have better heat resistance but falls short when durability under stress is concerned compared to well-manufactured PVC items.

Moreover, when considering cost-effectiveness as an advantage of PVC molding over alternatives like ABS or nylon—PVC typically presents a more affordable option without compromising quality or longevity. Each material has unique strengths; however, those seeking durability combined with versatility often find themselves gravitating toward what is known about the benefits of using vinyl-based products like those produced through pvc injection molding techniques.

In conclusion, understanding what is involved in both pvc injection molding processes and how they compare against other materials provides valuable insights for industries aiming to optimize their production capabilities while ensuring high-quality output at competitive prices.

What is PVC Injection For?

PVC injection molding is a versatile manufacturing process that caters to a wide range of applications across various industries. From everyday consumer goods to critical automotive components and vital construction materials, understanding what PVC injection is for can illuminate its significance in modern manufacturing. Let’s delve deeper into the specific applications of PVC injection molding.

Applications in Consumer Goods

The flexibility and durability of PVC make it an ideal choice for items that require both aesthetic appeal and functional resilience. Whether it's colorful kitchen utensils or intricate decorative pieces, the capability of PVC molding allows manufacturers to create diverse designs while maintaining cost-effectiveness.

Moreover, the ease of customization in PVC molding enables brands to cater to specific market demands quickly. This adaptability not only enhances product variety but also meets consumer expectations for quality and design. As a result, many companies are turning towards PVC injection molding as their go-to solution for creating high-demand consumer goods.

Use in Automotive Parts

In the automotive industry, understanding what is PVC injection for can significantly impact vehicle performance and safety features. Many automotive parts such as dashboards, paneling, and even wiring insulation utilize PVC due to its lightweight nature and resistance to wear and tear. The application of PVC injection molding ensures that these components are not only durable but also contribute positively to overall vehicle aesthetics.

Additionally, the cost-effectiveness of using PVC means that manufacturers can produce high-quality parts without breaking the bank—allowing them to pass savings onto consumers while maintaining safety standards. As vehicles continue evolving toward advanced technology integration, the role of PVC molded components becomes increasingly crucial in enhancing functionality without compromising on quality.

Role in Construction and Infrastructure

The construction sector has embraced what is PVC injection for by utilizing this method for pipes, fittings, and various building materials essential for infrastructure development. The inherent strength and resistance properties of PVC make it perfect for applications where durability is paramount—think plumbing systems or electrical conduits that need longevity under pressure or harsh conditions.

Moreover, with growing environmental concerns regarding traditional materials like metal or wood, using PVC offers an eco-friendlier alternative that still meets rigorous building codes and standards. As urbanization continues globally, relying on innovative solutions like PVC injection molding helps ensure sustainable growth while addressing infrastructure needs effectively.

What is the Advantage of PVC Molding?

When it comes to manufacturing, understanding the advantages of PVC molding can make all the difference in your project’s success. PVC injection molding stands out due to its cost-effectiveness, durability, and environmental considerations, making it a popular choice across various industries. Let’s dive into these benefits and see why many are asking, What is the advantage of PVC molding?

Cost-Effectiveness of PVC Injection Molding

One of the most compelling reasons businesses opt for PVC injection molding is its cost-effectiveness. The process allows for high-volume production with minimal waste, which translates to lower overall costs per unit. Moreover, materials used in what is PVC injection molding are often less expensive than alternatives like ABS or polycarbonate, making it an attractive option for budget-conscious projects.

Additionally, the efficiency of the PVC injection molding processing guide showcases how streamlined operations can further reduce labor and production costs. With quicker cycle times and reduced material expenses, manufacturers can maximize profits while maintaining product quality. Thus, when evaluating options for mass production, it's clear that choosing what is PVC injection for your needs can be financially savvy.

Durability and Longevity of PVC Products

Durability is another significant advantage that sets PVC products apart from other materials on the market. Products made using what is PVC molding exhibit excellent resistance to impact, chemicals, and moisture—qualities that ensure they stand the test of time in various applications. Whether used in consumer goods or construction components, these durable characteristics mean fewer replacements and repairs over time.

Moreover, this longevity contributes to overall customer satisfaction as consumers appreciate products that last longer without compromising performance. As industries increasingly seek reliable materials that do not wear out easily under stress or environmental factors, understanding what is PVC injection becomes crucial for making informed decisions about product design and materials selection. Investing in durable solutions means investing in your brand's reputation.

Environmental Considerations

As sustainability becomes a pressing concern globally, choosing eco-friendly materials has never been more important—and here’s where PVC shines brightly! While some may question its environmental impact initially associated with plastic production processes, advancements have made modern what is PVC injection molding much more sustainable than ever before. Manufacturers are now utilizing recycled content and implementing greener practices throughout their operations.

Furthermore, products created through what is PVC molding are often recyclable at their end-of-life stage—an essential factor contributing to a circular economy approach within industries today. By opting for environmentally conscious practices in production processes like those found in leading pvc injection molding manufacturers’ strategies—companies can significantly reduce their carbon footprint while still delivering quality products to consumers who care about sustainability.

PVC Injection Molding Processing Guide

When it comes to understanding the intricacies of PVC injection molding, a structured approach is essential. This section will walk you through the key components of the process, from its step-by-step execution to the equipment involved and common challenges faced by manufacturers. By gaining insights into this PVC injection molding processing guide, you’ll be well-equipped to appreciate its significance in various industries.

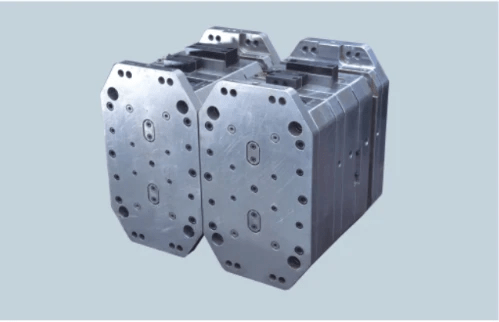

Step-by-Step Overview of the Process

What is PVC injection molding? It begins with heating raw PVC material until it reaches a molten state suitable for shaping. The molten plastic is then injected into a precisely designed mold under high pressure, allowing it to fill every cavity and detail. Once cooled, the mold opens, and the newly formed product is ejected, ready for finishing touches or assembly.

This process is not just about speed; it’s also about precision. Each step in PVC injection molding must be carefully controlled to ensure that the final product meets stringent quality standards. The ability to create complex shapes with high accuracy makes this method particularly appealing for industries ranging from consumer goods to automotive parts.

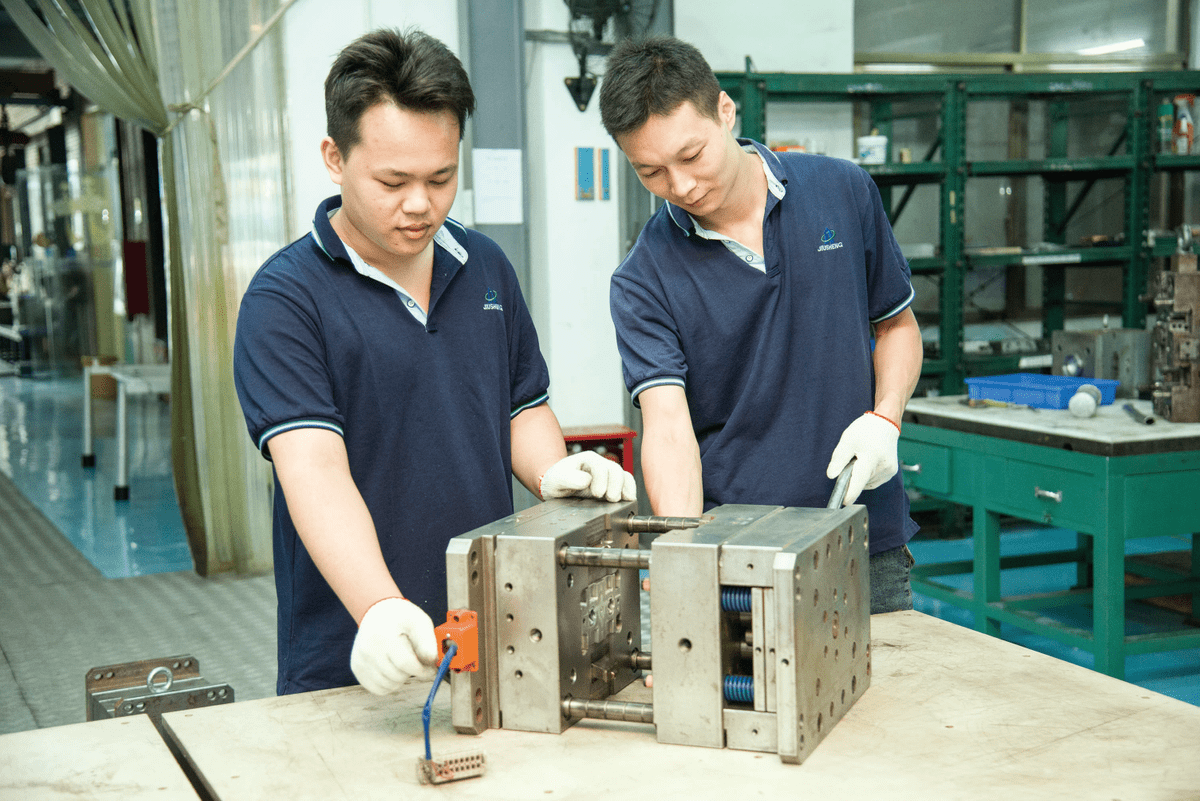

Key Equipment and Technology Used

The heart of what is PVC molding lies in its specialized machinery and technology. Key equipment includes injection molding machines, which are designed specifically for processing thermoplastics like PVC. These machines consist of a hopper for feeding raw materials, a heated barrel for melting them, and an injection unit that forces the molten material into molds.

In addition to traditional machinery, advancements in technology have introduced automation and robotics into the process. This enhances efficiency while reducing human error—making it easier than ever for manufacturers to produce high-quality products consistently. Understanding these tools provides insight into why many companies are turning towards reputable PVC injection molding manufacturers for their production needs.

Common Challenges and Solutions

Like any manufacturing process, what is PVC injection for can come with its own set of challenges—ranging from material inconsistencies to machine malfunctions. One common issue is warping or shrinkage during cooling; this can affect product dimensions adversely if not managed correctly during production planning stages.

To combat these challenges effectively, manufacturers often employ precise temperature controls and advanced monitoring systems throughout the production cycle. Additionally, working closely with experienced suppliers can help identify potential pitfalls before they become costly problems down the line. By being proactive rather than reactive when addressing these issues, companies can capitalize on what is the advantage of PVC molding: cost-effectiveness paired with durability.

Leading PVC Injection Molding Manufacturers

When diving into the world of PVC injection molding, it's essential to recognize the key players shaping the industry. Notable companies in this field are not just manufacturers; they are innovators pushing the boundaries of what is possible with PVC molding. From large multinational corporations to specialized local businesses, these manufacturers are pivotal in advancing technology and sustainability in PVC injection processes.

Notable Companies in the Industry

Several notable companies dominate the PVC injection molding landscape, each bringing unique strengths to the table. Companies like BASF and Westlake Chemical have established themselves as leaders by consistently delivering high-quality materials and innovative solutions for various applications.

Innovations from Top Manufacturers

The innovations emerging from top manufacturers in PVC injection molding are nothing short of remarkable. Many companies are investing heavily in research and development to enhance material properties, improve processing techniques, and reduce environmental impact. For instance, advancements in bio-based PVC formulations and more energy-efficient machinery have revolutionized how we think about what is PVC injection for? These innovations not only improve product performance but also align with growing consumer demands for sustainability.

Conclusion

As we wrap up our exploration of PVC injection molding, it’s clear that this versatile process plays a pivotal role in various industries. From consumer goods to automotive components, the applications are as diverse as the products themselves. Understanding what PVC injection molding is and its benefits can help businesses make informed decisions about their manufacturing needs.

Recap of PVC Injection Molding Basics

What is PVC injection molding? It’s a manufacturing process that involves injecting molten polyvinyl chloride (PVC) into a mold to create customized parts and products. This method stands out for its ability to produce high-quality, durable items quickly and efficiently, which is why many industries rely on it for their production needs.

In addition to understanding what PVC molding entails, it's essential to recognize the advantages it offers over other plastic materials. The unique properties of PVC make it suitable for various applications, from flexible consumer goods to rigid construction components. With a focus on cost-effectiveness and durability, PVC injection molding continues to be a preferred choice among manufacturers.

Future Trends in PVC Molding

Looking ahead, the future of PVC injection molding appears promising with ongoing innovations in material science and processing technologies. As sustainability becomes increasingly important, more manufacturers are exploring eco-friendly formulations of PVC that maintain performance while reducing environmental impact. This aligns with global trends toward greener manufacturing practices and can enhance the appeal of products made through this process.

Moreover, advancements in automation and smart manufacturing are set to revolutionize how we approach what is PVC injection for? Enhanced precision and efficiency will likely lead to even greater applications across different sectors—paving the way for more complex designs and improved product quality. As technology evolves, so too will the capabilities of PVC injection molding.

Final Thoughts on Choosing PVC Products

When considering what is the advantage of PVC molding? Cost-effectiveness, durability, and versatility stand out as key factors that make it an attractive option for manufacturers across various industries. The decision to choose PVC products should also take into account specific application requirements—ensuring they align with performance expectations.

For those looking into sourcing or working with pvc injection molding manufacturers, it's crucial to evaluate their expertise and innovations within the field. Selecting a reputable manufacturer can significantly impact product quality and project success rates—so do your homework! Ultimately, embracing the benefits of PVC can lead your business toward sustainable growth while delivering high-quality results.