Introduction

In the world of manufacturing, understanding plastic injection molding costs is crucial for businesses aiming to optimize production and maximize profits. As companies dive into this popular method of shaping plastics, they often find themselves asking, How much does plastic injection molding cost? This question opens the door to a myriad of factors that influence the overall price, from material selection to tooling expenses.

Understanding Plastic Injection Molding Costs

Plastic injection molding costs can vary significantly based on several key components. The process itself involves injecting molten plastic into a mold, which then cools and solidifies into the desired shape. However, determining how to calculate injection mold cost requires a clear grasp of each element involved—ranging from raw materials to labor and overhead expenses.

Key Factors Influencing Costs

Several factors play a pivotal role in shaping the overall injection molding cost. Material selection is one of the most significant influencers; different plastics come with varying price tags that can dramatically affect budget estimates. Additionally, tooling and mold design expenses must be considered—these initial investments can be substantial but are essential for achieving high-quality production runs.

Importance of Accurate Cost Estimation

Accurate cost estimation in plastic injection molding is not just beneficial; it's vital for sustainable business practices. Miscalculating these costs can lead to financial pitfalls or missed opportunities in competitive markets. By understanding how much does injection molding cost per kg or how much does injection molding cost in China, businesses can make informed decisions that enhance profitability while ensuring quality remains uncompromised.

Overview of Plastic Injection Molding

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to create various parts and products. This method allows for high-volume production with precision and efficiency, making it a popular choice for many industries. Understanding the intricacies of this process can illuminate how much does plastic injection molding cost and why accurate cost estimation is crucial.

Definition and Process

At its core, plastic injection molding is about transforming raw plastic material into finished goods through a series of steps. First, the selected thermoplastic resin is heated until it becomes molten, then injected into a precisely designed mold under high pressure. Once the material cools and solidifies, the mold opens to release the finished product—a process that can be repeated thousands of times with minimal variation in quality.

This method is not only efficient but also versatile; it can produce intricate designs that would be difficult or impossible with other manufacturing techniques. As industries increasingly seek to optimize production costs, understanding how to calculate injection mold cost becomes essential for businesses aiming to maximize profitability while maintaining quality standards.

Applications Across Industries

Plastic injection molding finds applications across a wide range of industries including automotive, consumer goods, medical devices, electronics, and more. From car dashboards to household items like containers and toys, almost every sector benefits from this technology's ability to produce complex shapes with high precision at scale. The question How much does injection molding cost? often varies depending on the specific application and industry requirements.

In sectors like healthcare where compliance with strict regulations is paramount, precision in design and production can significantly influence overall project costs—essentially highlighting how much does injection molding cost per kg when factoring in both materials and regulatory considerations.

Advantages of Plastic Injection Molding

The advantages of plastic injection molding are numerous; one primary benefit is its ability to produce large quantities at relatively low costs per unit as production scales up. Additionally, this method offers excellent repeatability—ensuring each part produced meets stringent specifications without significant variations in quality or performance over time.

Moreover, compared to alternative manufacturing processes like 3D printing or CNC machining, low volume injection molding cost tends to be more favorable when considering mass production scenarios where initial tooling investment pays off over time through reduced per-unit costs. Thus understanding these advantages helps businesses make informed decisions about their manufacturing strategies while keeping an eye on overall plastic injection molding costs.

Factors That Affect Plastic Injection Molding Cost

Understanding the factors that influence plastic injection molding cost is crucial for manufacturers and businesses alike. The interplay between material selection, tooling expenses, and production volume can significantly impact overall costs. By examining these elements closely, companies can better strategize their budgeting and production processes.

Material Selection Impact

When it comes to plastic injection molding cost, the choice of material is one of the most significant factors to consider. Different materials come with varying price tags; for instance, high-performance resins may cost more than standard plastics but offer superior durability and performance. Additionally, how much does injection molding cost per kg? This question often hinges on the specific material used, as some materials are heavier or more expensive than others.

Furthermore, understanding the properties of various materials can lead to better decisions that ultimately reduce costs in other areas—like tooling wear or post-processing requirements. For example, selecting a less abrasive material can lower mold maintenance expenses over time. Ultimately, a thoughtful approach to material selection not only addresses immediate financial concerns but also contributes to long-term savings in production efficiency.

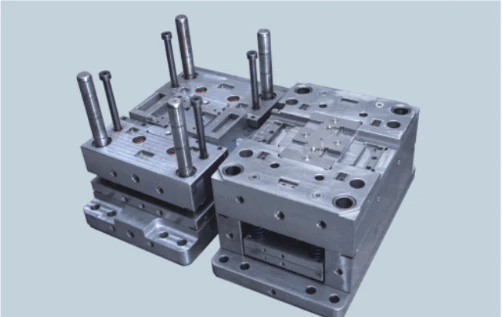

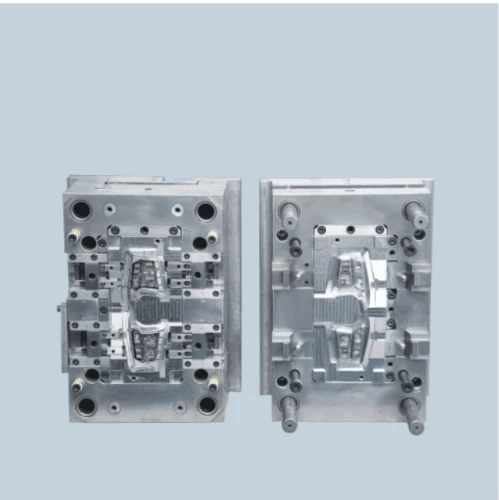

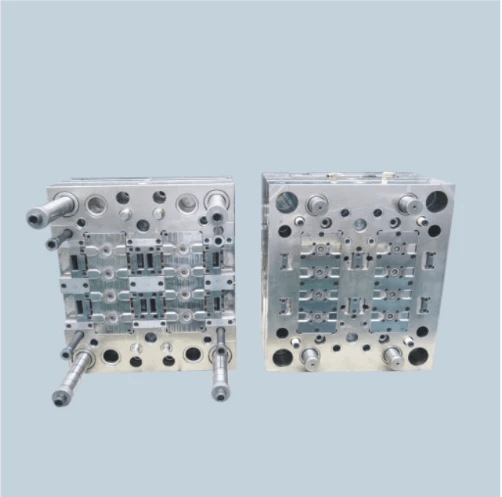

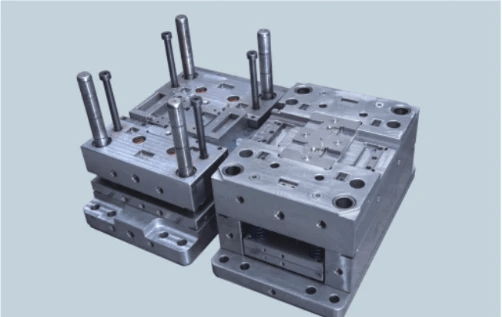

Tooling and Mold Design Expenses

Tooling and mold design expenses are another major contributor to overall injection molding costs. The complexity of the mold directly affects how much does plastic injection molding cost? A simple mold might be relatively inexpensive to produce, while intricate designs require advanced engineering and higher initial investment. This upfront expenditure can be daunting but is essential for achieving high-quality parts in larger quantities.

Moreover, investing in high-quality molds often pays off by reducing cycle times and minimizing defects during production runs—leading to better savings down the line. It's also worth noting that low volume injection molding costs may not justify elaborate designs; simpler molds can provide adequate results without breaking the bank when producing small quantities. Therefore, aligning mold design with production goals is key to optimizing both initial costs and long-term profitability.

Production Volume Considerations

Production volume plays a critical role in determining plastic injection molding costs as well; larger runs generally lower per-unit expenses due to economies of scale. How much does injection molding cost in China? Often lower than many Western countries due to cheaper labor and material sourcing options—this makes it an attractive choice for high-volume projects seeking competitive pricing without sacrificing quality.

However, when dealing with low volume injection molding costs, companies may face higher per-piece prices since fixed costs like tooling are spread over fewer units produced. This creates a unique challenge: balancing quality with quantity while keeping an eye on budget constraints is essential for success in this competitive landscape. Ultimately, understanding your production needs will guide you toward making informed decisions that align with both your financial goals and market demands.

How to Calculate Injection Mold Cost

Calculating the cost of injection molding can feel like navigating a maze, but fear not! With a clear understanding of the cost components and the right tools, you can unveil the mystery behind plastic injection molding cost. This section will guide you through how to calculate injection mold cost accurately, ensuring you're prepared for any project.

Breakdown of Cost Components

To grasp how much does plastic injection molding cost, it’s essential to break down its various components. The primary costs include material expenses, tooling costs (which involve designing and manufacturing molds), labor fees, and overheads related to production facilities. Each of these factors contributes significantly to the overall injection molding cost, making it crucial to evaluate them carefully.

Material selection plays a vital role in determining how much does injection molding cost per kg; different materials have varying price points that can impact your budget significantly. Tooling costs are often one of the largest expenses upfront; creating a high-quality mold requires precision and expertise. Additionally, labor costs can fluctuate based on regional wage differences and production volume—especially relevant when considering low volume injection molding costs.

Utilizing Software for Accurate Estimates

In today’s digital age, utilizing software for accurate estimates is no longer optional but essential for anyone looking into plastic injection molding costs. There are specialized programs designed to streamline the calculation process by factoring in all relevant variables—material types, production volumes, and even regional pricing differences like how much does injection molding cost in China? These tools help provide a more precise estimate than manual calculations ever could.

Moreover, advanced software solutions often come equipped with features that allow users to simulate different scenarios—changing materials or adjusting production volumes—to see how these changes affect overall costs. This capability is invaluable when trying to optimize your budget while maintaining quality standards in your projects. It also assists manufacturers in providing clients with realistic quotes that reflect true market conditions.

Case Study: Baoyuan's Approach to Cost Calculation

Let’s take a closer look at Baoyuan's approach as an illustrative case study on how they calculate their injection mold costs effectively. By employing both traditional methods and modern software tools, Baoyuan has managed to streamline their estimation process significantly while keeping their prices competitive within the industry landscape. Their meticulous breakdown includes examining each component's contribution toward overall plastic injection molding cost.

Baoyuan also emphasizes transparency with clients by providing detailed quotes that outline every aspect of their calculations—from material selection down to labor rates—which helps clients understand why certain choices may increase or decrease their final bill. This kind of clarity is crucial for building trust and ensuring satisfaction among customers who frequently ask questions like “how much does plastic injection molding cost?” or “what about low volume injection molding costs?”

Through this case study, it becomes evident that accurate calculations hinge on thorough analysis combined with innovative technology—a winning formula for success in today's competitive market!

Regional Cost Variations

How Much Does Injection Molding Cost in China?

In China, the plastic injection molding cost is often lower than in many Western countries due to reduced labor expenses and efficient manufacturing processes. On average, businesses might find that how much does injection molding cost per kg can be surprisingly economical compared to other regions. However, it's essential to factor in shipping costs and potential tariffs when calculating the total expense of outsourcing production to China.

Chinese manufacturers offer competitive pricing structures that attract companies from various industries; however, quality control can sometimes be an issue. This means that while initial costs may be lower, additional investments might be necessary for quality assurance measures. Ultimately, understanding how much does injection molding cost in China involves not just looking at base prices but also considering the complete supply chain.

Comparing Costs Globally

When comparing global costs for injection molding, one must consider several factors that influence pricing across different regions. For example, North America and Europe typically have higher labor rates and stricter regulations, which can drive up the plastic injection molding cost significantly compared to Asia. In contrast, countries like India and Vietnam are emerging as competitive alternatives due to their growing capabilities and lower operational costs.

It's also important to note that while some regions may offer lower base prices for low volume injection molding cost projects, hidden fees or longer lead times could offset those savings. Therefore, businesses should perform a comprehensive analysis of how much does plastic injection molding cost globally before making decisions on where to source their production needs. This approach ensures a more accurate picture of total expenditures involved in the process.

Low Volume Injection Molding Cost Insights

Low volume injection molding presents unique challenges when it comes to understanding overall costs associated with this manufacturing method. Generally speaking, low volume projects tend to have higher per-unit expenses due to fixed tooling costs being spread over fewer units produced—this makes knowing how much does injection molding cost per kg particularly important for budgeting purposes.

For companies looking into low volume production runs, it's crucial to evaluate whether investing in custom molds is viable or if alternative methods like 3D printing could provide better financial outcomes without sacrificing quality. Additionally, exploring regional differences can help identify areas where low volume injection molding cost might be minimized through strategic partnerships or localized sourcing options.

Ultimately, grasping these insights allows manufacturers and designers alike to navigate the complexities of pricing effectively while maintaining high standards of quality and efficiency throughout their projects.

Understanding Injection Molding Cost per Kilogram

How Much Does Injection Molding Cost per kg?

The average cost of plastic injection molding can vary significantly based on several factors, but generally speaking, how much does injection molding cost per kg? Prices typically range from $2 to $15 per kilogram depending on material choice, complexity of the mold design, and production volume. For instance, low volume injection molding costs might be on the higher end due to setup expenses that don’t scale down with smaller production runs.

Understanding these costs is vital for any business planning to engage in plastic manufacturing. If you're asking yourself how to calculate injection mold cost accurately, consider not just raw materials but also labor and overhead associated with each kilogram produced. Moreover, geographic factors play a role; for example, how much does injection molding cost in China? Often lower than in Western countries due to cheaper labor and materials.

Material Weight and Pricing Strategies

Material weight significantly influences the overall plastic injection molding cost. Different plastics have varying densities; thus understanding how material weight affects your pricing strategy is crucial for accurate budgeting. For example, lighter materials may reduce shipping costs while heavier materials could enhance durability but increase overall expenses.

When calculating costs based on weight, always factor in not just the price of raw materials but also their performance characteristics which could affect long-term value. Companies often find themselves strategizing around these weights: should they opt for a cheaper material that may compromise quality or invest more upfront for durability? The decision ultimately hinges on balancing short-term costs against long-term gains—an essential consideration when evaluating low volume injection molding cost versus high-volume runs.

Real World Examples of Cost Efficiency

To illustrate effective pricing strategies related to plastic injection molding cost, let’s look at some real-world examples that highlight efficiency gains through smart decisions about material use and process optimization. One company shifted from using a standard ABS material that was costing them around $10/kg to a more efficient polycarbonate blend at $8/kg without sacrificing quality or performance—resulting in significant savings over time.

Another case involved redesigning molds which reduced waste during production; this adjustment led to lower overall material consumption and helped decrease their average how much does plastic injection molding cost metric substantially. In essence, these examples show that businesses must continually assess both their processes and choices in materials—not only do they affect immediate costs like how much does injection molding cost per kg, but they also influence overall profitability in the long run.

Conclusion

In the world of plastic injection molding, understanding and managing costs is crucial for manufacturers and businesses alike. With various factors influencing plastic injection molding cost, it's essential to adopt strategies that can lead to significant savings. By knowing how to calculate injection mold cost accurately, companies can optimize their production processes and enhance profitability.

Strategies for Reducing Injection Molding Costs

To effectively reduce injection molding costs, businesses should start by selecting the right materials that balance quality and expense. Additionally, investing in efficient tooling and mold design can significantly decrease long-term expenses associated with production. For those dealing with low volume injection molding costs, considering alternative manufacturing methods or negotiating bulk material purchases can also yield substantial savings.

The Role of Sophisticated Software in Estimation

Sophisticated software plays a pivotal role in estimating plastic injection molding costs accurately. These tools allow manufacturers to input various parameters such as material type, production volume, and design complexity to generate precise estimates. By utilizing technology for cost estimation, companies can better understand how much does plastic injection molding cost in different scenarios and make informed decisions about their projects.

Final Thoughts on Cost Accuracy and Quality

Ultimately, achieving a balance between cost accuracy and quality is vital in the realm of plastic injection molding. Companies must continually evaluate their processes to ensure they are not sacrificing quality for lower costs or vice versa. As the industry evolves, staying informed about trends like how much does injection molding cost per kg will empower manufacturers to remain competitive while delivering high-quality products.