Introduction

Plastic injection moulded components have become an integral part of various industries, offering a wide range of applications and benefits. Baoyuan's expertise in plastic injection moulding ensures high-quality, precision components for diverse needs. Exploring the versatility of injection moulded parts showcases the endless possibilities in design and functionality.

Importance of Plastic Injection Moulded Components

Custom plastic injection molding plays a crucial role in manufacturing products for industries such as automotive, electronics, and medical devices. The components of plastic injection mold include cores, cavities, and cooling channels that contribute to the overall efficiency of the process.

Baoyuan's Expertise in Plastic Injection Moulding

Baoyuan's advanced capabilities in plastic injection moulding encompass a wide range of materials and production techniques, ensuring top-notch quality and performance. With extensive experience in custom plastic injection molding, Baoyuan is well-equipped to meet unique project requirements with precision and expertise.

Exploring the Versatility of Injection Moulded Parts

Injection moulded parts can be made from various types of plastics such as polypropylene, polystyrene, and polyethylene. The flexibility in material selection allows for customization based on specific project needs. This versatility extends to the design and functionality of injection moulded parts, making them ideal for a multitude of applications.

The Role of Plastic Injection Moulded Components

Plastic injection moulded components play a crucial role in various industries, providing custom solutions for a wide range of applications. These components are used in automotive, medical, consumer goods, and electronics industries, among others, to create durable and precise parts that meet specific requirements.

Custom Plastic Injection Molding for Various Industries

Custom plastic injection molding offers a versatile solution for industries with unique design and functionality needs. Baoyuan's expertise in producing custom plastic injection moulded components allows for the creation of tailored parts that meet the exact specifications of different sectors, ensuring high-quality and reliable products. With advanced technology and a skilled team, Baoyuan can handle complex designs and intricate details to deliver precise and efficient solutions for various industries. Whether it's automotive, medical, or consumer goods, custom plastic injection molding provides the flexibility to produce parts that are durable, cost-effective, and perfectly suited to each industry's requirements.

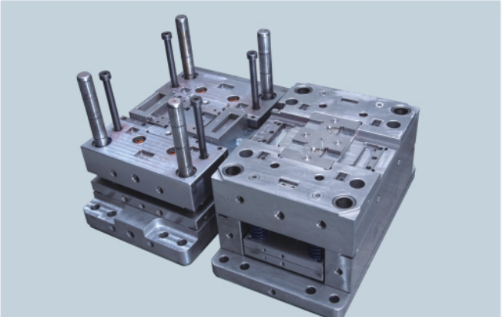

Understanding the Components of Plastic Injection Mold

The components of a plastic injection mold include the cavity, core, sprue, runner system, and ejection system. These elements work together to form the desired shape of the plastic part during the injection moulding process, ensuring accuracy and consistency in the final product.

The cavity and core are the primary components of a plastic injection mold, forming the interior and exterior surfaces of the part, respectively. The sprue is the channel through which molten plastic is injected into the mold, while the runner system distributes the plastic throughout the cavity. The ejection system then helps to remove the finished part from the mold once it has solidified, completing the injection moulding process.

Exploring Different Types of Injection Moulded Parts

Injection moulded parts can be made from a wide range of plastic materials, each with its own unique set of properties. For example, polypropylene (PP) is known for its high chemical resistance and thermal stability, making it ideal for use in the automotive and packaging industries. On the other hand, acrylonitrile butadiene styrene (ABS) offers excellent impact resistance and toughness, making it a popular choice for consumer electronics and medical devices. These different material options allow manufacturers to tailor their injection moulded parts to meet specific performance requirements for various applications.

Advantages of Using Injection Moulded Components

Plastic injection moulded components offer a range of advantages that make them an ideal choice for various industries. Firstly, the durability and strength of injection moulded products ensure that they can withstand the demands of everyday use, making them a reliable option for manufacturers and consumers alike. Additionally, the versatility and flexibility in design and functionality allow for endless possibilities in creating innovative and practical products that meet the specific needs of different applications. Finally, the cost-effectiveness of plastic injection moulded components makes them a budget-friendly option without sacrificing quality or performance, making it a win-win situation for businesses and consumers. With these advantages in mind, it's clear why plastic injection moulding continues to be a popular choice in manufacturing today.

Durability and Strength of Injection Moulded Products

Plastic injection moulding results in products that are incredibly durable and strong, capable of withstanding harsh conditions without compromising their integrity. This makes them suitable for a wide range of applications across industries such as automotive, aerospace, medical devices, consumer goods, and more. The ability to produce robust components through custom plastic injection molding ensures that manufacturers can rely on these parts for long-term use without concerns about premature failure.

Versatility and Flexibility in Design and Functionality

One of the key advantages of using injection moulded components is their versatility in design and functionality. The process allows for intricate designs with varying thicknesses, textures, colors, and finishes to be achieved with precision. This level of flexibility ensures that manufacturers can create highly customized parts tailored to specific requirements, enabling innovative solutions to be developed across different sectors.

The ability to create intricate designs with varying thicknesses, textures, colors, and finishes through injection moulding not only allows for highly customized parts but also opens up opportunities for innovative solutions in a wide range of industries. Whether it's creating unique shapes for consumer products or developing specialized components for industrial machinery, the versatility of design and functionality offered by injection moulded components provides endless possibilities for manufacturers to explore.

Cost-Effectiveness of Plastic Injection Moulded Components

The cost-effectiveness of plastic injection moulded components is a significant advantage for businesses looking to optimize their production processes. Injection moulding offers high production output rates while minimizing material waste, resulting in lower overall manufacturing costs per unit produced. This efficiency makes it an attractive option for companies seeking to maximize their return on investment while maintaining high-quality standards.

Furthermore, the versatility of plastic injection moulding allows for the production of complex and intricate components with ease. This means that businesses can create a wide range of products using the same manufacturing process, reducing the need for multiple production methods and equipment. As a result, companies can streamline their operations and achieve cost savings through economies of scale.

Baoyuan's Advanced Mould Design and Injection Moulding Process

Baoyuan has honed its expertise in designing and manufacturing both single-color and double-color plastic products. With a keen eye for detail and precision, Baoyuan ensures that every plastic injection moulded component meets the highest standards of quality. Whether it's a simple or complex design, Baoyuan's skilled team is capable of delivering outstanding results.

Expertise in Designing and Manufacturing Single-Color and Double-Color Plastic Products

Baoyuan excels in creating single-color and double-color plastic products that cater to a wide range of industries. The company's extensive experience allows them to understand the specific requirements of each project, ensuring that the final product is not only visually appealing but also highly functional. From intricate designs to simple shapes, Baoyuan's expertise shines through in every plastic injection moulded component they produce.

Baoyuan's commitment to quality assurance and precision in injection moulding sets them apart from their competitors. Their state-of-the-art manufacturing processes and strict quality control measures ensure that each product meets the highest standards of durability and performance. Whether it's a single-color or double-color plastic product, clients can trust Baoyuan to deliver flawless results every time.

Quality Assurance and Precision in Injection Moulding

Quality assurance is at the core of Baoyuan's injection moulding process. Each step of the manufacturing process is carefully monitored to ensure that the final product meets the highest standards of durability, strength, and performance. With a keen focus on precision, Baoyuan guarantees that every plastic injection moulded component is free from defects and inconsistencies, providing customers with reliable and long-lasting solutions.

Baoyuan's commitment to quality assurance extends beyond the manufacturing process. The company also utilizes advanced software for mould design and production, ensuring that each component is precisely engineered to meet the exact specifications of the customer. By leveraging cutting-edge technology, Baoyuan is able to optimize the efficiency and accuracy of its injection moulding process, resulting in products that consistently exceed industry standards.

Baoyuan's Skilled Use of Software for Mould Design and Production

Baoyuan leverages advanced software tools for mould design and production, allowing them to create intricate designs with unparalleled accuracy. By utilizing cutting-edge technology, Baoyuan can bring even the most complex concepts to life while maintaining cost-effectiveness throughout the production process. This commitment to innovation sets Baoyuan apart as a leader in the field of plastic injection moulding.

Baoyuan's skilled use of software for mould design and production not only allows for intricate designs with unparalleled accuracy, but also streamlines the production process by reducing the margin for error. With the ability to visualize and test designs before production begins, Baoyuan can ensure that each mould meets the highest standards of quality and functionality. This dedication to precision and efficiency has solidified Baoyuan's reputation as an industry leader in plastic injection moulding.

Conclusion

Plastic injection moulded components are revolutionizing the manufacturing industry with their versatility and durability. As industries continue to demand custom plastic injection moulding for their specific needs, Baoyuan remains committed to excellence in producing high-quality components.

The Future of Plastic Injection Moulded Components

The future of plastic injection moulded components is bright, with endless possibilities for innovation and advancement. As technology continues to evolve, we can expect even more complex and intricate designs that push the boundaries of what is possible with injection moulding.

Baoyuan's Commitment to Excellence in Injection Moulding

Baoyuan's dedication to excellence in injection moulding is unwavering, as they continue to invest in advanced mould design and precision manufacturing processes. With a focus on quality assurance and customer satisfaction, Baoyuan sets the standard for superior plastic injection moulded components.

Embracing the Potential of Injection Moulded Components

It's time for industries to fully embrace the potential of injection moulded components and harness their benefits for enhanced product performance and cost-effectiveness. By leveraging the expertise of manufacturers like Baoyuan, businesses can unlock new opportunities for innovation and growth.