Introduction

In the world of manufacturing, understanding the costs associated with injection molding is crucial for businesses looking to optimize production and maximize profits. Injection molding cost estimation is the process of calculating all expenses related to producing parts through this method, which can significantly affect project budgets and timelines. With an accurate injection molding cost estimator, manufacturers can navigate the complexities of pricing and make informed decisions.

What is Injection Molding Cost Estimation?

Injection molding cost estimation involves assessing various factors that contribute to the overall expenses incurred during the production of molded parts. This includes material costs, labor expenses, mold design and manufacturing costs, as well as overheads associated with production facilities. By accurately estimating these costs, companies can better understand how to calculate the cost of injection molding and ensure their projects remain financially viable.

The Importance of Accurate Cost Estimations

Accurate cost estimations are vital for any business engaged in injection molding because they directly influence pricing strategies and profit margins. When companies fail to account for all variables—such as how much does it cost to make an injection mold or how much does injection molding cost per kg—they risk underpricing their products or facing unexpected financial challenges down the line. Therefore, leveraging tools like an Injection Molding Part Cost Calculator can provide invaluable insights into potential costs and help mitigate risks.

Overview of Injection Molding Cost Factors

The cost of injection molding is influenced by a multitude of factors that must be carefully considered during the estimation process. Key elements include material selection, mold complexity, production volume, labor rates in different regions (for instance, how much does injection molding cost in China?), and operational overheads. Understanding these factors allows manufacturers to create more accurate budgets while exploring strategies for reducing overall costs through efficient design and material choices.

Understanding Injection Molding Costs

When diving into the world of injection molding, understanding the costs involved is crucial. An injection molding cost estimator can provide insights into various factors that influence the overall expenses. By grasping these key elements, businesses can make informed decisions and optimize their production processes.

Key Variables Influencing Injection Molding Costs

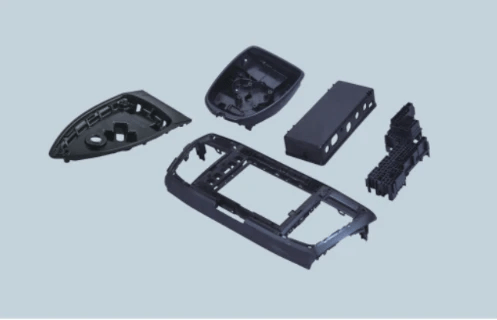

Several key variables significantly impact injection molding costs. First and foremost, the type of material selected plays a vital role; different materials have varying price points, affecting how much does injection molding cost per kg? Additionally, mold design complexity and manufacturing techniques contribute to the overall cost structure. Other factors include production volume, cycle time, and even geographic location—like how much does injection molding cost in China compared to other regions?

How to calculate the cost of injection molding?

Calculating the cost of injection molding involves multiple components that must be considered for accurate estimations. Start with raw material costs—this includes understanding how much does it cost to make an injection mold? Next, factor in labor costs associated with machine operation and maintenance. Finally, use an Injection Molding Part Cost Calculator to streamline this process; it will help you compile all relevant data and provide a clearer picture of your total expenses.

Common Misconceptions About Costs in Injection Molding

Many misconceptions surround the costs associated with injection molding that can lead businesses astray. One common myth is that lower initial mold costs always translate to savings; however, cheaper molds may lead to higher long-term production expenses if they wear out quickly or produce inferior parts. Additionally, some believe that overseas production is always cheaper without considering hidden fees or quality issues—understanding how much does injection molding cost in China versus local options is essential for making wise choices.

The Role of Material Selection

Impact of Material Choice on Costs

The type of material selected for a project is one of the most critical factors affecting the cost of injection molding. For instance, high-performance plastics like PEEK or Ultem may offer superior strength and thermal resistance but come with a hefty price tag compared to standard materials like ABS or polypropylene. Additionally, some materials require specific processing conditions or specialized molds, which can further inflate costs—making an injection molding cost estimator an essential tool for accurate budgeting.

Cost implications also extend to production volume; certain materials may be more economical at scale due to their properties or ease of processing. Therefore, when considering how much does injection molding cost per kg? it's crucial to factor in not just the raw material price but also its compatibility with your production needs and efficiency. Ultimately, choosing the right material involves balancing performance requirements with budget constraints.

How much does injection molding cost per kg?

On average, the cost of injection molding can vary widely depending on several factors—including material choice—leading many manufacturers to ask: how much does it cost per kg? Generally speaking, basic thermoplastics might range from $1 to $5 per kg while engineering-grade plastics could set you back anywhere from $5 up to $20 or more per kg. This variance highlights why utilizing an Injection Molding Part Cost Calculator is invaluable; it helps estimate costs based on specific project parameters.

Moreover, understanding these costs is crucial for businesses looking to optimize their budgets without compromising quality. By inputting different materials into an injection molding cost estimator, manufacturers can quickly see how changes in material selection impact overall pricing—allowing for informed decisions that align with both financial goals and product specifications.

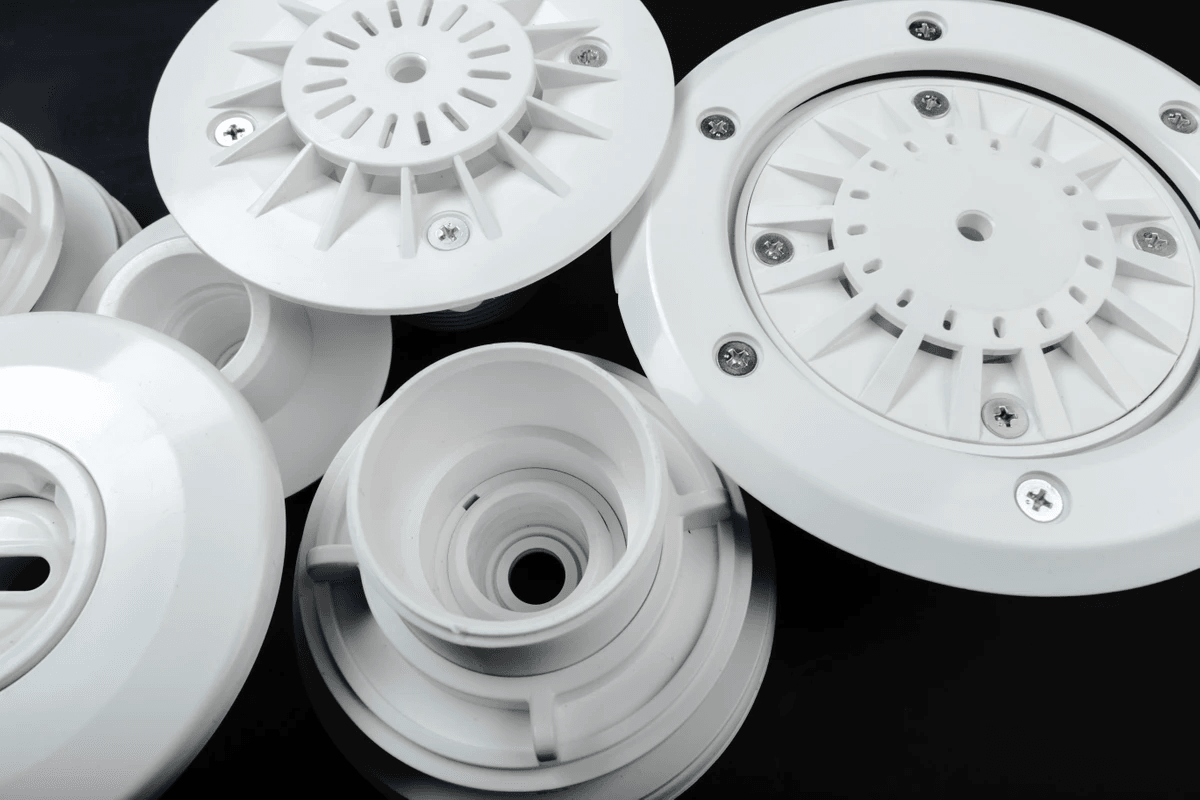

Popular Materials Used in Injection Molding

When discussing popular materials used in injection molding, a few stand out due to their versatility and affordability: ABS (Acrylonitrile Butadiene Styrene), Polypropylene (PP), and Nylon (PA) are among the favorites for various applications. ABS is celebrated for its toughness and ease of machining while polypropylene offers excellent chemical resistance at a lower price point—ideal for consumer products and packaging solutions alike.

In contrast, Nylon’s durability makes it perfect for applications requiring high strength-to-weight ratios but often at a higher initial investment—raising questions like how much does it cost to make an injection mold specifically designed for such materials? These considerations highlight why careful selection based on application needs is vital; after all, what works best isn’t always what’s cheapest upfront!

In summary, understanding material selection's role in your project's success will pay dividends not only when calculating costs but also when striving for quality outcomes in your final products.

Mold Design and Manufacturing Costs

How much does it cost to make an injection mold?

The cost of making an injection mold can range from a few thousand dollars to over a hundred thousand dollars based on several factors. Generally, simple molds may start around $1,000 to $5,000, while more complex designs could easily exceed $50,000 or more. To accurately gauge these expenses, it's wise to consider using an injection molding part cost calculator that takes into account all relevant variables.

Factors Affecting Mold Production Expenses

Several key factors influence mold production expenses beyond just the initial design complexity. Material selection plays a pivotal role; high-quality steel or aluminum molds typically come at a premium price but offer better durability and longevity. Additionally, labor costs—especially if you're considering how much does injection molding cost in China versus other regions—can significantly impact overall expenses.

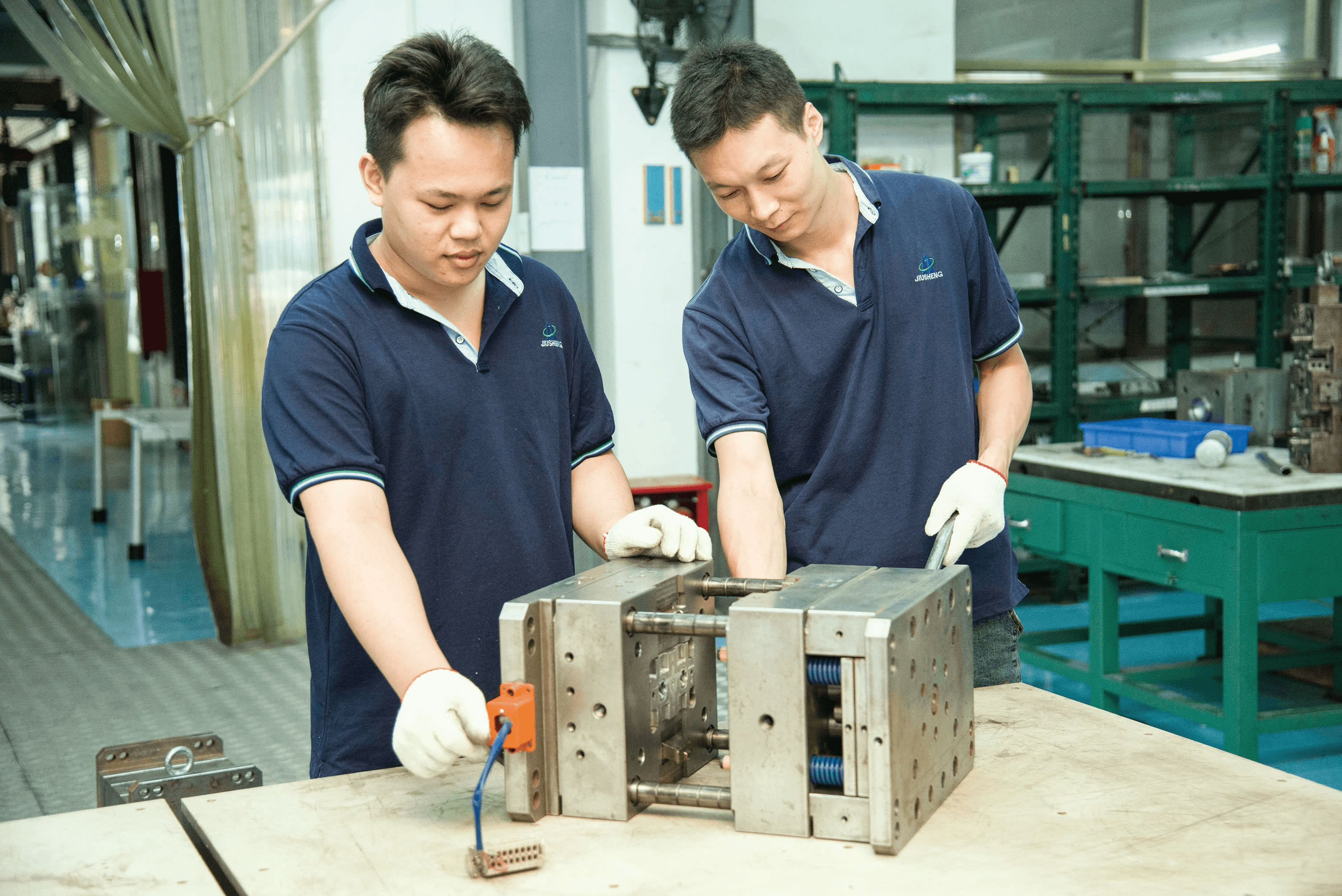

The Importance of Design Efficiency

Design efficiency is not just a buzzword; it's a critical component that can greatly affect the overall cost of injection molding. A well-designed mold reduces cycle time and minimizes defects during production, ultimately lowering costs per unit produced. By focusing on efficient designs from the outset and utilizing tools like an injection molding cost estimator early in the process, companies can ensure they remain within budget while maximizing output quality.

Location and Labor Costs

When it comes to injection molding, location and labor costs can significantly influence the overall cost of production. Different regions have varying wage scales, operational expenses, and logistical considerations that all play a role in determining how much it will cost to manufacture your parts. Understanding these factors is crucial for anyone looking to optimize their injection molding budget.

How much does injection molding cost in China?

China has become a dominant player in the injection molding industry due to its competitive pricing and established manufacturing infrastructure. On average, the cost of injection molding in China can range from $0.50 to $3.00 per kg, depending on material choice and complexity of the mold design. To get a precise figure tailored to your project, using an injection molding cost estimator can provide valuable insights into specific costs involved.

Comparing Labor Costs Across Different Regions

Labor costs are a key variable when calculating the overall expense of injection molding projects. For instance, countries like China offer lower labor rates compared to Western nations such as the United States or Germany, which can lead to substantial savings on large-scale production runs. However, it's essential not just to focus on labor costs; other factors like quality control and shipping logistics also contribute significantly to the total cost of injection molding.

Cost Implications of Local vs. Overseas Production

Deciding between local and overseas production for your injection molded parts involves weighing several factors beyond just initial costs. While overseas production might offer lower prices—often calculated through an injection molding part cost calculator—there may be hidden expenses such as longer lead times, potential tariffs, and shipping fees that can erode those savings quickly. Ultimately, understanding how much does it cost to make an injection mold in different locations will help you make informed decisions that align with your budgetary constraints.

Using Cost Calculators

In the world of injection molding, having a reliable injection molding cost estimator at your disposal can be a game changer. These calculators streamline the process of estimating costs, saving you time and reducing the risk of errors. By inputting various parameters, you can get a clearer picture of what to expect when it comes to the cost of injection molding.

Benefits of an Injection Molding Part Cost Calculator

One major benefit of using an injection molding part cost calculator is its ability to provide quick estimates based on real-time data. You can easily adjust variables like material type, mold complexity, and production volume to see how they affect overall costs. Additionally, these calculators often incorporate industry standards and benchmarks that help ensure your estimates are grounded in reality.

Another advantage is that they allow for scenario planning; by tweaking different parameters, you can explore how changes impact your budget. For instance, if you're curious about how much does injection molding cost per kg for different materials, a good calculator will provide that insight instantly. Ultimately, using an injection molding cost estimator helps you make informed decisions while minimizing financial risks.

How to Use the Cost Calculator Effectively

To make the most out of your injection molding part cost calculator, start by gathering all relevant data before entering it into the tool. This includes specifics about the design specifications and material choices as well as any additional features or requirements for your project. The more accurate and comprehensive your input data is, the better your output estimates will be.

Next, familiarize yourself with all available features within the calculator; many tools offer advanced options like automatic updates on market prices or historical data comparisons. This allows you not only to calculate costs but also to analyze trends over time—essentially answering questions like how much does it cost to make an injection mold in today's market? Finally, always double-check your results against other sources or expert opinions for added validation.

Key Metrics to Measure with Cost Calculators

When utilizing an injection molding part cost calculator, there are several key metrics you should focus on for effective budgeting and planning purposes. First and foremost is total estimated production costs; this figure gives you a baseline understanding of what you'll need financially before moving forward with manufacturing decisions.

Next up is per-unit pricing—this metric helps answer crucial questions like how much does injection molding cost in China compared to local production? Understanding labor costs across different regions can significantly influence where you decide to manufacture parts for optimum profitability.

Lastly, keep track of material costs per kg as this directly impacts overall expenses in any project involving plastic components. By measuring these key metrics consistently through your calculations, you'll be better equipped to strategize for both immediate needs and long-term goals in your manufacturing processes.

Conclusion

In the world of manufacturing, understanding injection molding costs is crucial for businesses aiming to optimize production and maximize profit margins. The journey through cost estimation reveals that various factors, from material selection to labor costs, play significant roles in determining the overall expenses involved. By employing strategies such as using an injection molding cost estimator and engaging with experts, companies can navigate these waters more effectively.

Final Thoughts on Injection Molding Costs

Cost estimation in injection molding is not just about crunching numbers; it’s about making informed decisions that affect product quality and profitability. As we’ve explored, knowing how to calculate the cost of injection molding involves considering multiple variables—from mold design to material choice. Ultimately, having a clear picture of these costs can empower manufacturers to make strategic choices that enhance their competitive edge.

Strategies for Cost Optimization

To optimize the cost of injection molding, businesses should first leverage tools like the Injection Molding Part Cost Calculator. This calculator provides valuable insights into how much does it cost to make an injection mold and helps identify areas where savings can be made. Additionally, regular reviews of supplier contracts and exploring alternative materials can significantly lower how much does injection molding cost per kg without sacrificing quality.

Working with Experts Like Baoyuan for Success

Partnering with experts like Baoyuan can streamline the process of estimating costs and enhance overall production efficiency. Their experience allows companies to better understand how much does injection molding cost in China compared to local options while ensuring high-quality output at competitive prices. By collaborating with professionals who specialize in this field, businesses can focus on innovation while leaving intricate details like precise cost estimations in capable hands.