Introduction

Navigating the world of plastic injection pricing can feel like trying to solve a Rubik's Cube blindfolded. With various factors influencing injection molding costs, understanding what drives these prices is essential for businesses looking to optimize their production processes. This guide aims to shed light on the value of plastic injection molding services and help you make informed decisions.

Understanding Plastic Injection Pricing

When it comes to plastic injection price, many variables come into play that can affect your bottom line. From the choice of materials to the complexity of mold designs, each aspect contributes significantly to the overall cost of your project. By grasping these elements, you can better strategize your investment in injection molding and potentially save money in the long run.

Factors Influencing Injection Molding Costs

Several key factors influence injection molding costs, making it crucial for businesses to be aware of them before diving into a project. Material choice plays a pivotal role; different types of injection moldable plastics come with varying price tags and performance characteristics. Additionally, the complexity of mold design and anticipated production volume can further sway plastic injection prices, impacting both initial investments and future scalability.

The Value of Plastic Injection Molding Services

Investing in high-quality plastic injection molding services is more than just a transaction; it's about establishing a partnership that adds value over time. A well-executed mould injection moulding process not only ensures precision but also enhances product durability and performance across various industries. Ultimately, understanding this value proposition will empower you to choose wisely when selecting a provider for your mold plastic injection needs.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that transforms raw plastic materials into finished products through the use of molds. This method involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired shape. It's a highly efficient technique that allows for mass production while ensuring precision and consistency in each part produced.

Overview of Injection Molding Process

The injection molding process begins with the selection of suitable injection moldable plastics, which are then heated until they become pliable. Once melted, the plastic is injected into a custom-designed mold, where it takes on the shape of the cavity. After cooling, the mold opens to release the finished product, ready for further processing or assembly.

This method is not only quick but also cost-effective when producing large volumes of parts, making it an attractive option for businesses looking to optimize their production costs without compromising quality. Understanding this process can help companies better navigate plastic injection price negotiations and appreciate the value offered by professional plastic injection molding services.

Types of Injection Moldable Plastics

There are several types of plastics used in injection molding, each offering unique properties that cater to different applications. Common materials include thermoplastics like ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and polypropylene; these can be heated and reshaped multiple times without losing their integrity. On the other hand, thermosetting plastics such as epoxy resins harden permanently after being molded and cannot be remelted.

Choosing the right type of plastic is crucial as it directly impacts both production efficiency and end-product performance. Factors such as strength requirements, temperature resistance, and flexibility all play significant roles in determining which injection moldable plastics are suitable for specific projects—ultimately influencing overall plastic injection price.

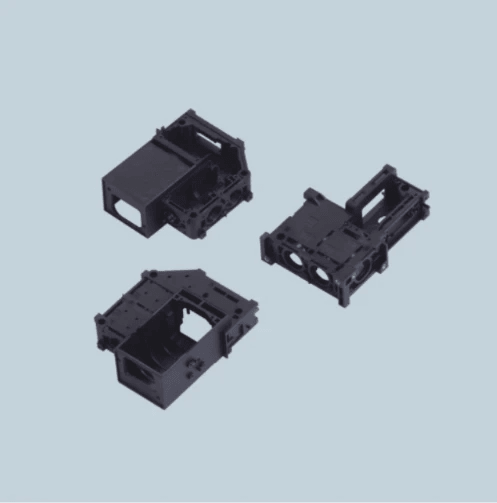

Common Uses in Various Industries

Plastic injection molding finds applications across numerous industries due to its versatility and efficiency in producing complex shapes at scale. In automotive manufacturing, it's used for everything from dashboard components to intricate exterior trims—providing durability while reducing weight compared to metal alternatives. The consumer goods sector also benefits significantly from this technology; everyday items like containers, toys, and household appliances are often produced using mould injection moulding techniques.

Moreover, medical devices rely heavily on precise plastic parts created through this method due to stringent safety standards that must be met. As industries continue evolving with new technologies and materials, understanding how various sectors utilize plastic injection molding will help businesses make informed decisions regarding their own manufacturing needs—and ultimately lead them towards finding competitive plastic injection prices.

Key Factors Affecting Plastic Injection Price

Material Choice and Its Impact

The selection of materials is one of the most crucial determinants in calculating plastic injection price. Different types of injection moldable plastics carry varying costs; for example, high-performance engineering plastics may command a premium compared to standard thermoplastics. Furthermore, the properties required from the final product—such as strength, flexibility, or temperature resistance—can dictate not only material choice but also the overall expenses associated with mould injection moulding processes.

In addition to base material costs, additives or colorants can further inflate prices depending on specific project requirements. Therefore, understanding how different materials affect both performance and cost is vital for any business looking to optimize their investment in plastic injection molding. Ultimately, selecting the right material can lead to enhanced product quality and potential long-term savings.

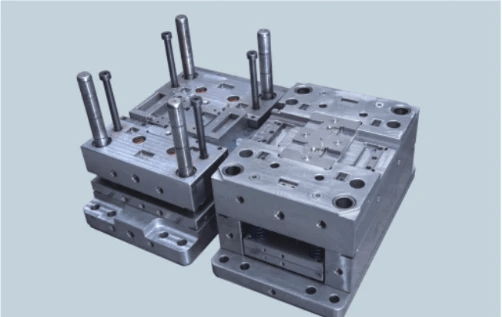

Complexity of the Mold Design

The intricacy of mold design plays a significant role in shaping plastic injection prices as well. Simple molds are generally less expensive due to reduced machining time and lower manufacturing complexity; however, more elaborate designs often require advanced features like undercuts or intricate cooling channels that drive up costs significantly. In this context, investing in a well-thought-out mold design can yield better results during production while impacting pricing structures.

Moreover, custom molds may necessitate additional iterations and testing before achieving optimal functionality—this adds time and expense that must be factored into the overall plastic injection molding price equation. Therefore, companies should consider collaborating closely with experienced teams who understand how design intricacies affect both performance outcomes and budget constraints when developing their mold plastic injection solutions.

Production Volume Considerations

Production volume is another critical factor influencing plastic injection pricing dynamics. Typically speaking, higher volumes lead to lower per-unit costs due to economies of scale; however, initial setup costs—including tooling—must still be accounted for when assessing total expenses associated with large-scale production runs. Conversely, smaller batches might incur higher per-unit prices because fixed costs are spread across fewer items.

Additionally, businesses must evaluate whether they plan on scaling production over time as this could impact initial investments in molds or machinery tailored specifically for particular volumes or product lines. Understanding these nuances helps companies navigate their options more effectively while ensuring they receive competitive quotes from various providers offering different levels of service within the realm of plastic injection molding services.

Comparing Plastic Injection Quotes

When it comes to plastic injection molding, comparing quotes can feel like deciphering a secret code. However, understanding how to request accurate quotes and what to look for in different services can save you both time and money. With the right approach, you can ensure that you’re getting the best value for your investment in plastic injection molding services.

How to Request Accurate Quotes

To get the most precise plastic injection price, start by providing detailed specifications of your project. This includes dimensions, tolerances, material requirements (like specific injection moldable plastics), and production volumes. The more information you provide upfront, the less chance there is for misunderstandings later on—leading to a smoother process and fewer surprises when it comes time to discuss costs.

Don't hesitate to ask potential suppliers about their experience with similar projects; this can give insight into their capabilities in mould injection moulding. Moreover, consider requesting samples or prototypes if possible; seeing their work firsthand will help gauge quality before making a commitment. By being thorough in your request for quotes, you'll be setting yourself up for success in finding the right plastic injection molding partner.

Evaluating Different Injection Molding Services

When evaluating different plastic injection molding services, it's crucial not just to focus on price alone but also on quality and reliability. Look at each company's track record—how long have they been in business? Do they specialize in certain types of mold plastic injection or industries? Customer reviews and testimonials can be invaluable resources here.

Consider also the technology they use; advanced machinery often leads to better precision and efficiency in producing molds. Additionally, inquire about their quality control processes; robust systems ensure that every piece meets stringent standards before it leaves the facility. Ultimately, balancing cost against these factors will help you choose a service that aligns with your expectations for both price and quality.

Understanding Quote Components

Diving into a quote without understanding its components is like reading a menu without knowing what any of the dishes are! A typical quote for plastic injection molding should break down costs associated with materials (like specific types of injection moldable plastics), labor, machine time, and any additional fees such as design or prototyping services.

The Role of Experienced Teams

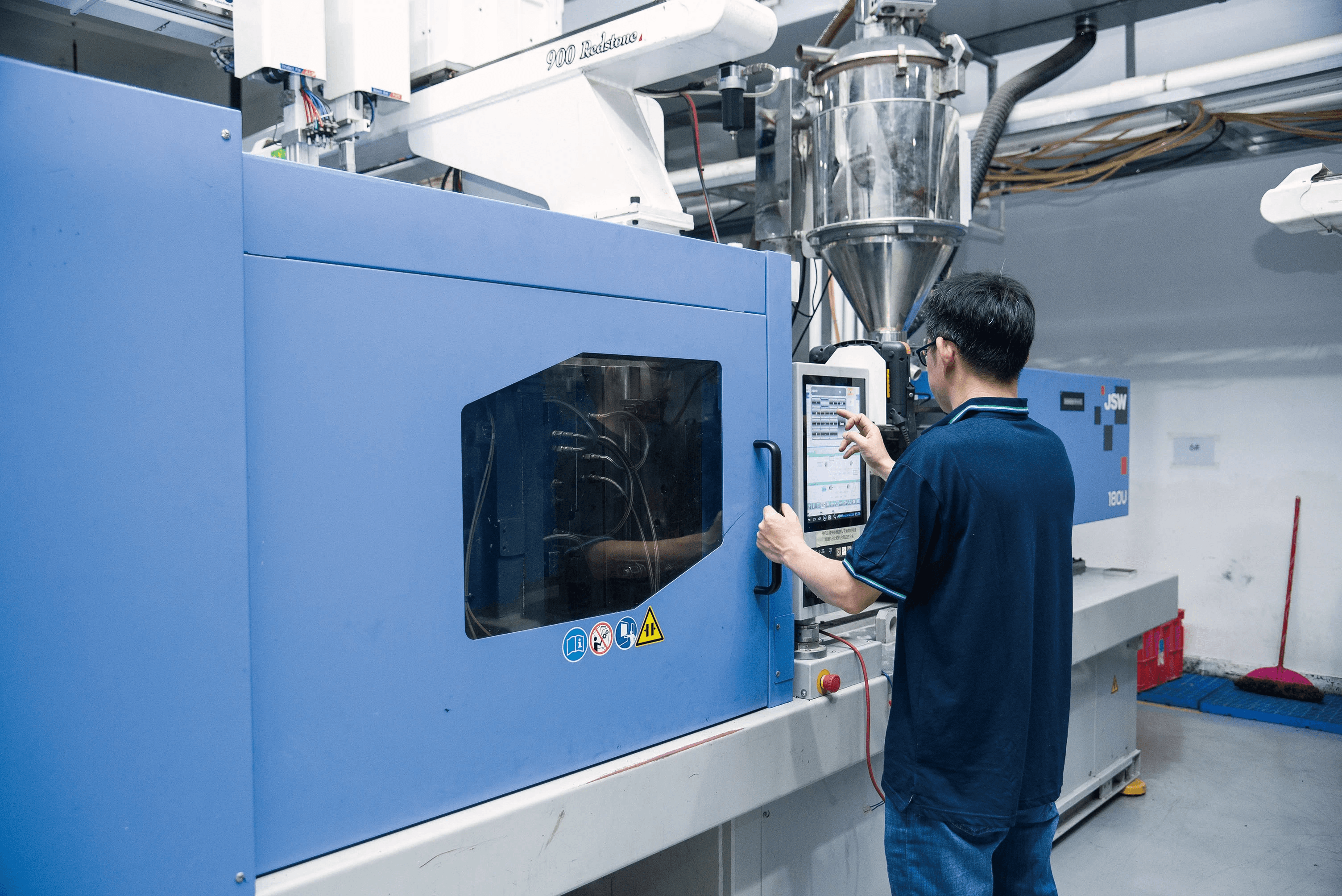

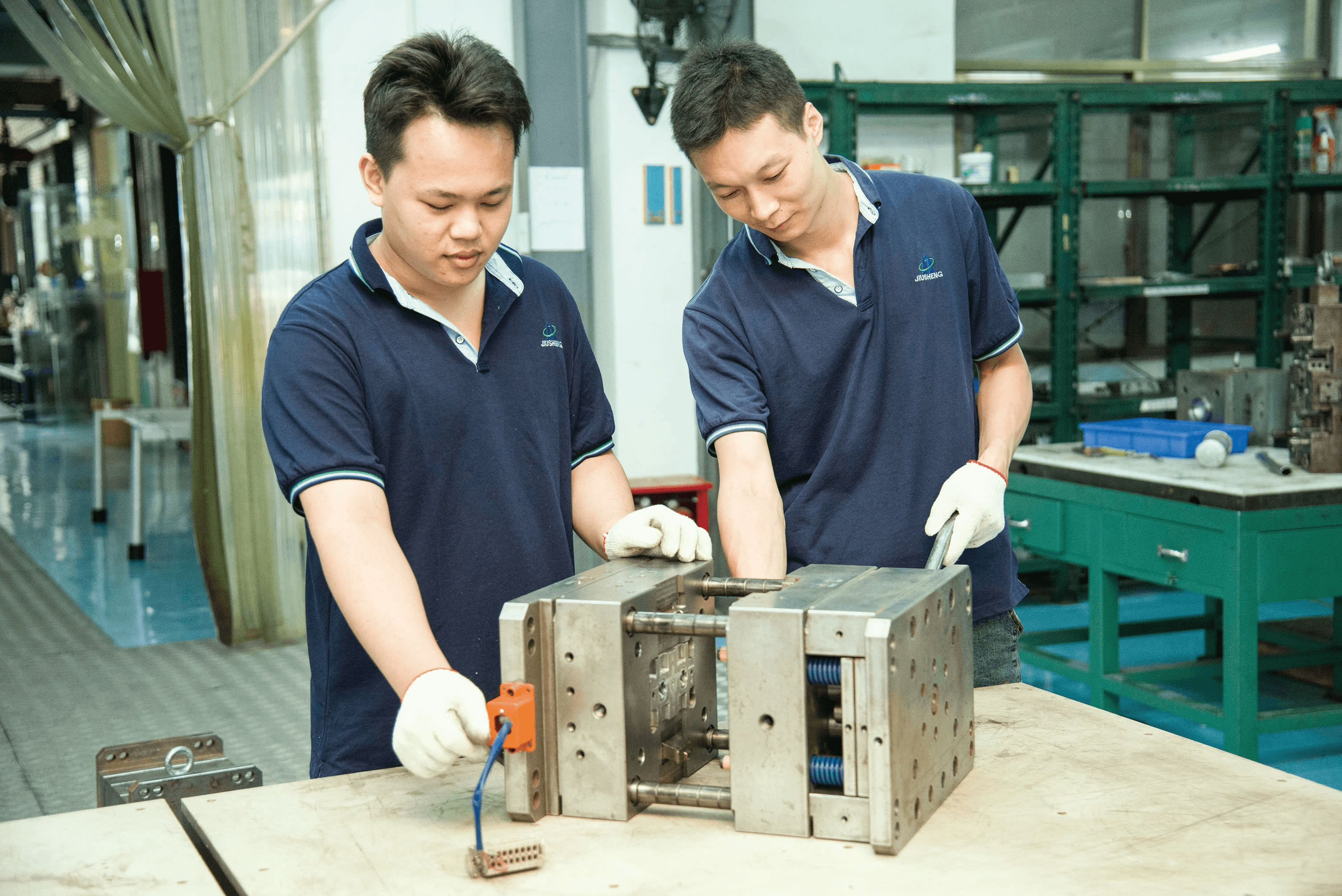

Importance of Skilled Technicians

Skilled technicians bring a wealth of knowledge to the table, ensuring that every aspect of the injection molding process runs smoothly. From selecting the right injection moldable plastics to fine-tuning machine settings, their expertise minimizes errors and waste. This proficiency not only enhances product quality but also helps in reducing overall costs associated with mould injection moulding.

Moreover, experienced teams can quickly troubleshoot issues that arise during production, preventing delays that could inflate plastic injection prices. Their familiarity with various materials allows them to make informed decisions on which plastics will best suit specific applications. In a competitive market where precision is key, having skilled technicians can set a company apart from its competitors.

Highlighting Baoyuan's Expertise

At Baoyuan, we pride ourselves on our dedicated team of professionals who excel in all facets of plastic injection molding services. Our technicians undergo continuous training to stay updated with industry advancements and best practices in mold plastic injection techniques. This commitment to excellence ensures that our clients receive high-quality products at competitive prices.

Baoyuan's extensive experience means we can handle complex projects with ease while maintaining efficiency and accuracy throughout the production process. Our team’s ability to adapt and innovate is crucial for meeting diverse customer needs without compromising on quality or increasing costs unnecessarily. By choosing Baoyuan, you’re partnering with experts who prioritize your success.

Quality Assurance in Injection Molding

Quality assurance is a cornerstone of our approach at Baoyuan when it comes to injection molding services. We implement rigorous testing protocols at every stage—from initial design through production—to ensure that each item meets stringent quality standards before it leaves our facility. This thoroughness helps mitigate risks associated with defects that could lead to higher plastic injection prices down the line.

Our commitment to quality extends beyond just meeting specifications; we aim for excellence in every product we produce using state-of-the-art technology and techniques in mould injection moulding. By investing time and resources into quality assurance processes, we ensure consistent results for our clients across various industries using different types of injection moldable plastics. Ultimately, this dedication translates into cost savings for customers seeking reliable solutions without sacrificing craftsmanship.

Cost-Saving Tips for Customers

Strategies for Reducing Injection Molding Expenses

One effective strategy for reducing plastic injection molding expenses is to carefully select your materials. The choice of injection moldable plastics can significantly impact both the initial costs and long-term durability of your products. Opting for standard materials that are readily available may save you money compared to specialized or custom materials that often come with a higher price tag.

Another way to cut costs is by simplifying your mold design as much as possible. Complex designs may require more intricate mould injection moulding processes, which can increase both production time and costs. Collaborating closely with your plastic injection molding service provider early in the design phase allows for efficient adjustments that streamline production and minimize expenses.

Lastly, consider increasing your production volume if feasible; larger orders typically lead to lower per-unit costs due to economies of scale in manufacturing. While this approach requires careful forecasting and planning, it can yield significant savings in the long run when dealing with plastic injection prices.

Benefits of Long-Term Partnerships

Establishing a long-term partnership with a reliable plastic injection molding company can yield numerous benefits beyond just cost savings. When you work consistently with one provider, they become familiar with your specific needs and preferences, allowing them to optimize processes tailored specifically for you—often resulting in lower prices over time due to decreased setup times and improved efficiency.

Moreover, loyal customers often gain access to exclusive discounts or pricing structures not available to new clients seeking one-off projects. This loyalty translates into better rates on future orders as well as priority service during peak times—both essential factors when considering overall plastic injection price management.

Additionally, a strong relationship fosters open communication about potential cost-saving measures or innovations that could enhance product quality while reducing expenses across multiple production runs—making it a win-win situation for everyone involved!

Choosing the Right Plastic Injection Company

Selecting the right company for your plastic injection molding needs plays a pivotal role in managing costs effectively while ensuring high-quality results. Start by researching various providers’ reputations; look out for reviews or testimonials from previous clients focusing on their experiences regarding both pricing transparency and product quality—essential elements when evaluating any potential partner.

Next, don't hesitate to ask potential partners about their capabilities concerning different types of moulds and materials used in their processes; this information will help determine whether they align well with your project requirements at competitive prices. A good provider should be willing not only to discuss their services but also offer insights into how they could help optimize designs or material choices that could ultimately lead towards reduced overall costs.

Finally, ensure that any prospective company has robust quality assurance measures in place; cutting corners here might save money upfront but could lead down costly roads later on if defects arise within produced items—a risk no one wants when navigating through varying plastic injection prices!

Conclusion

Navigating the world of plastic injection price can feel like wandering through a maze, but understanding the key components can simplify the journey. Injection molding is not just about cost; it's about value and quality. By grasping what influences these prices, you can make informed decisions that benefit your project and bottom line.

Making Sense of Plastic Injection Prices

From the choice of injection moldable plastics to the complexity of the mold design, each element contributes to the final figure on your quote. Understanding these aspects will empower you to negotiate better deals and optimize your production process.

By evaluating different quotes based on their components—such as material costs and production volume—you'll gain insights into what makes one service provider more appealing than another. Remember, while a lower price might be tempting, it’s essential to consider what you're sacrificing in terms of quality and reliability. Ultimately, making sense of plastic injection prices involves balancing cost with long-term value.

Importance of Quality in Molding Services

Quality in plastic injection molding services is paramount for achieving durable products that meet industry standards. A well-crafted plastic injection molding mold ensures precision and consistency in every piece produced, which directly affects your product's performance and marketability. Cutting corners on quality may save money upfront but could lead to costly defects or recalls down the line.

Investing in high-quality mould injection moulding processes not only enhances product reliability but also boosts customer satisfaction—an invaluable asset for any business. Skilled technicians who understand the intricacies of injection molding are essential for maintaining these high standards throughout production runs. Therefore, prioritizing quality when selecting a service provider will pay off handsomely over time.

Finding the Best Injection Molding Partner

Choosing the right partner for your plastic injection molding needs is crucial for success in today's competitive landscape. Look for companies that demonstrate expertise in various types of injection moldable plastics and have a solid track record with complex projects similar to yours. A reliable partner will not only understand how to manage costs effectively but also focus on delivering superior results.

Long-term partnerships with experienced teams can provide significant advantages, such as reduced rates over time due to consistent business relationships or shared knowledge about best practices in mould design and production efficiency. As you search for an ideal fit, prioritize those who emphasize both cost-effectiveness and unwavering commitment to quality assurance throughout their processes. With careful consideration, you'll find a partner capable of elevating your projects while keeping an eye on that all-important plastic injection price.