Introduction

Injection molding is a cornerstone of modern manufacturing, offering efficiency and precision in producing a wide array of plastic components. However, understanding the various factors that contribute to injection molding price is essential for businesses looking to optimize production costs. From material selection to labor expenses, the intricacies of injection molding pricing can significantly influence overall profitability.

Understanding Injection Molding Cost Factors

When diving into the world of injection molding, one must consider several cost factors that play a crucial role in determining the final price. These include material costs, labor rates, and tooling expenses—each impacting how much does an injection mold cost? Additionally, geographical location can affect these costs substantially; for instance, how much does injection molding cost in China? The interplay between these elements creates a complex landscape that requires careful navigation for manufacturers aiming to maximize their budgets.

Why Injection Molding Pricing Matters

Understanding injection molding pricing is not just an academic exercise; it has real-world implications for businesses striving to remain competitive. Accurate knowledge of how much does injection molding cost per kg can help companies make informed decisions about production runs and material choices. Moreover, recognizing the nuances of pricing can lead to better negotiations with suppliers and ultimately result in significant savings.

The Importance of Cost Efficiency in Molding

Cost efficiency is paramount in the realm of injection molding; it directly affects a company's bottom line and market positioning. By mastering how to calculate injection mold cost accurately, manufacturers can identify areas where they can cut expenses without sacrificing quality or performance. Furthermore, understanding this aspect allows companies like PCBWay to offer competitive pricing while maintaining high standards—ensuring that clients receive value without compromising on their project goals.

Breakdown of Injection Molding Pricing

Understanding the various components that contribute to injection molding pricing is crucial for manufacturers and businesses alike. Each element plays a significant role in determining the overall cost, impacting both production efficiency and profit margins. Let’s delve into the intricacies of injection molding costs, starting with material expenses.

Material Costs and Their Impact

Material costs are often one of the most significant factors when discussing how much does injection molding cost? The type of resin used can drastically affect the injection molding price; high-performance materials tend to be more expensive than standard options. Additionally, fluctuations in raw material prices can lead to unpredictable costs, making it essential for companies to stay informed about market trends.

When considering how much does injection molding cost in China?, it's important to note that local suppliers may offer more competitive rates on materials due to lower production costs. However, importing specialized materials might negate those savings, so evaluating your specific needs is vital. Ultimately, selecting the right material not only influences immediate expenses but also impacts product quality and durability.

Labor and Overhead Considerations

Labor and overhead are other critical components influencing how much does an injection mold cost? Skilled labor is necessary for operating machinery and ensuring quality control, which can vary significantly based on geographic location. In regions with higher labor costs, such as North America or Western Europe, total production expenses will be noticeably elevated compared to manufacturing hubs like China.

Overhead considerations also include facility maintenance, utilities, and administrative expenses that support the production process. Companies must factor these ongoing costs into their pricing models when calculating their overall budget for injection molding projects. By understanding these elements thoroughly, businesses can better strategize around their operational expenditures.

Tooling Costs Explained

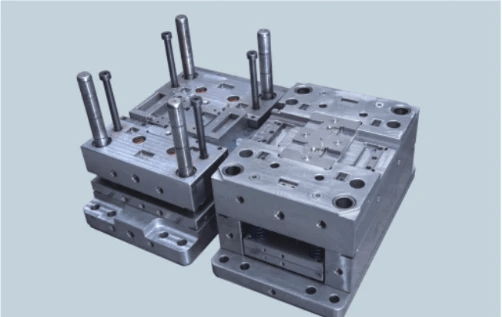

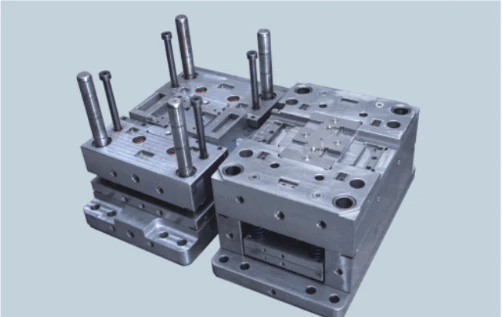

Tooling costs represent a substantial portion of initial investments in any injection molding project; thus asking how to calculate injection mold cost? becomes crucial for financial planning. The complexity of the mold design directly correlates with its price; intricate molds require more time and resources to produce than simpler designs do. This means that upfront tooling expenses can vary widely based on design specifications.

Moreover, while some manufacturers may initially balk at high tooling prices, it’s essential to consider them as long-term investments—especially if you're looking at large-scale production runs where durability matters most. In this context, understanding PCBWay injection molding price can provide valuable insights into competitive tooling options available in global markets like China versus domestic alternatives elsewhere.

In summary, a thorough breakdown of these factors—material costs, labor overheads, and tooling expenses—can empower manufacturers to make informed decisions about their projects while keeping an eye on overall profitability within the realm of injection molding pricing strategies.

How Much Does an Injection Mold Cost?

Factors Influencing Mold Costs

Several key factors can significantly affect the cost of an injection mold. First and foremost is the complexity of the mold design; intricate designs require more time and expertise to create, thus increasing costs. Additionally, the choice of materials used for both the mold and the final product will impact pricing; high-quality steel molds are more durable but also pricier than aluminum alternatives.

Another important consideration is production volume; higher volumes may justify investing in a more expensive mold that lasts longer and produces parts faster. Labor costs also come into play, particularly if specialized skills are needed for setup or operation of complex machinery like an injection molding machine. Understanding these factors is essential when asking How to calculate injection mold cost? as they contribute directly to your budget.

Average Price Ranges for Molds

So how much does an injection mold typically cost? On average, simple molds can range from $1,000 to $5,000 while more complex designs can start at $5,000 and soar upwards of $100,000 or more depending on their specifications. For instance, molds used in high-volume production runs often command higher prices due to their durability and precision requirements.

If you’re curious about how much does injection molding cost per kg? It’s essential to factor in not just the initial mold price but also ongoing expenses such as material costs and labor for each unit produced. This holistic view gives you a clearer picture of your total investment in terms of both upfront costs and long-term financial commitments.

Cost Comparison Across Regions

When considering How much does injection molding cost in China?, it's vital to note that regional differences can lead to significant variations in pricing structures. Generally speaking, manufacturing costs are lower in China due to cheaper labor and raw material expenses compared to Western countries. However, this doesn't mean that quality should be sacrificed; many Chinese factories maintain high standards while offering competitive PCBWay injection molding prices.

Comparing prices across regions reveals that while initial mold costs may be lower in China—often ranging from 30% to 50% less than those in North America or Europe—shipping fees and potential tariffs must also be factored into your overall budget assessment. Thus, when evaluating where to produce your parts or how much you're willing to invest upfront for efficient production runs globally—knowledge is power!

Injection Molding Costs in China

When it comes to injection molding, many businesses are turning their eyes toward China for manufacturing. The injection molding price in China can be significantly lower than in other regions, making it an attractive option for companies looking to cut costs without compromising quality. Understanding how much does injection molding cost in China is essential for anyone considering this route.

Advantages of Manufacturing in China

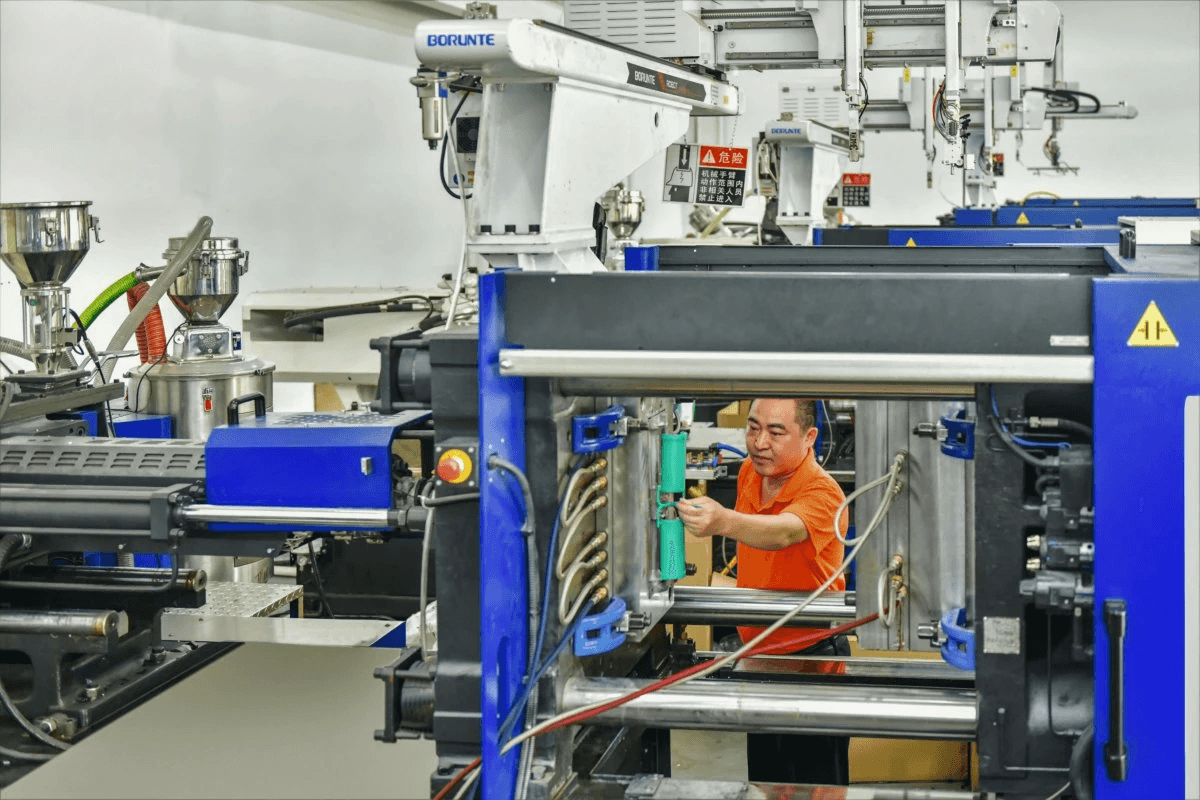

One of the primary advantages of manufacturing in China is the reduced labor costs, which directly influence the overall injection molding price. The vast workforce allows factories to operate at scale, leading to economies of scale that can dramatically lower production expenses. Additionally, China's established supply chains and infrastructure mean quicker turnaround times and increased efficiency—perfect for businesses eager to bring products to market swiftly.

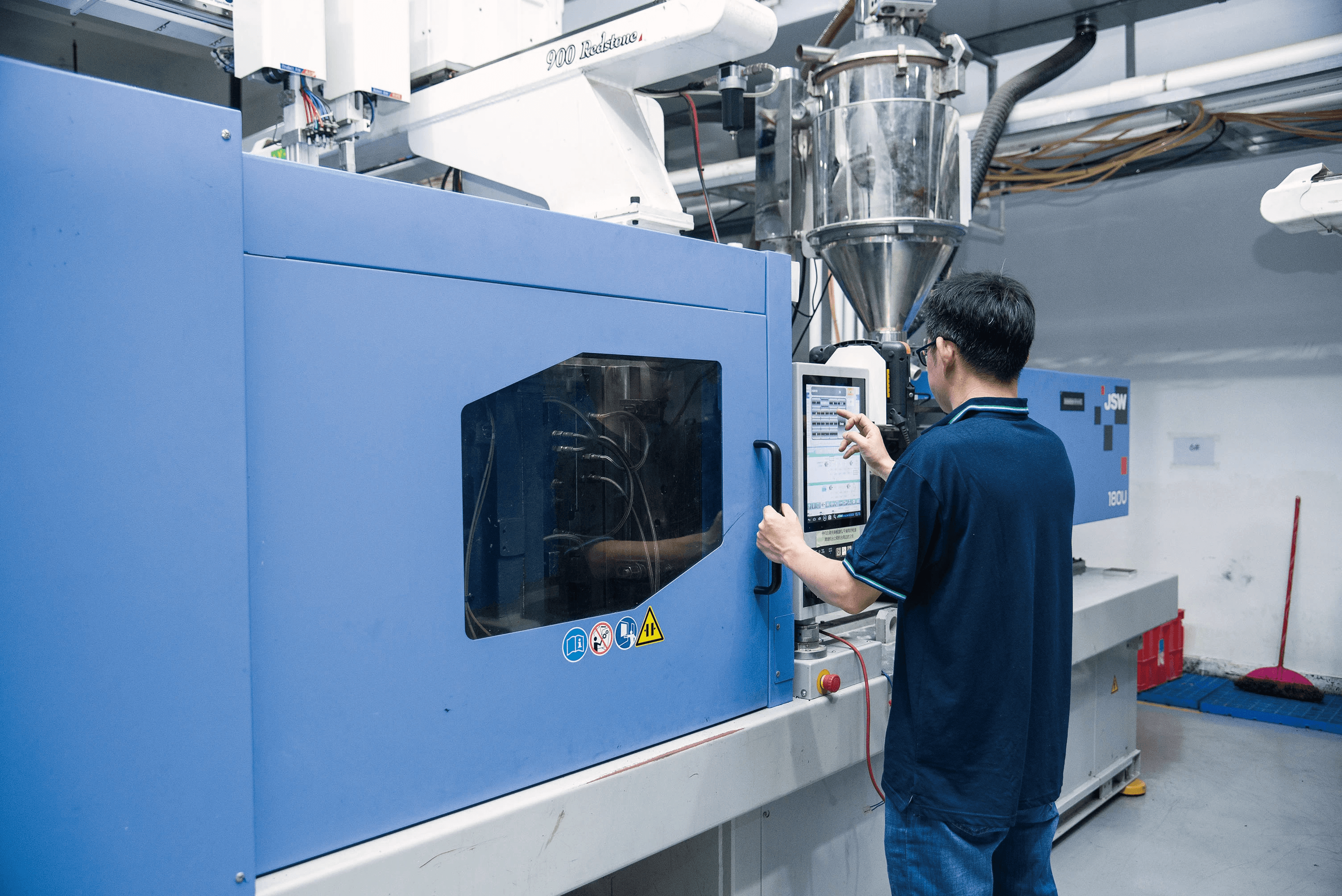

Another perk is the access to advanced technology and machinery at competitive prices, including high-quality injection molding machines. This means that companies can benefit from modern techniques without breaking the bank on equipment costs. Moreover, many Chinese manufacturers have a wealth of experience and expertise when it comes to injection molding, ensuring that even complex designs can be produced effectively.

Typical Costs in Chinese Factories

So how much does injection molding cost per kg when produced in Chinese factories? Generally speaking, prices can vary widely based on several factors including material type, mold complexity, and order volume. However, typical costs often range from $1 to $5 per kg depending on these variables.

For those asking how much does an injection mold cost specifically within China, initial tooling investments can start around $3,000 but may climb higher for more intricate designs or larger molds. It's also worth noting that while upfront costs might seem lower compared to other countries, hidden fees such as shipping and tariffs could impact your overall budget—making it essential to factor these into your calculations.

Case Study: PCBWay Injection Molding Pricing

To illustrate these points further, let’s take a closer look at PCBWay's injection molding pricing structure as a case study. PCBWay offers competitive rates with a starting price around $0.50 per kg for basic plastic parts using common materials like ABS or PP—a steal compared to many Western manufacturers!

Their transparent pricing model allows clients not only to see how much does injection molding cost but also helps them understand what influences these prices—such as design complexity or production volume adjustments over time. By collaborating with experts like PCBWay who provide clear insights into how to calculate injection mold cost accurately while offering flexibility in production runs, companies stand a better chance of managing their budgets effectively.

Per Kilogram Cost Analysis

Understanding the per kilogram cost of injection molding is crucial for businesses looking to optimize their production budgets. This metric provides a clear view of how material and processing costs impact the overall injection molding price. By analyzing these costs, manufacturers can make informed decisions that enhance profitability while maintaining quality.

How Much Does Injection Molding Cost Per Kg?

The question How much does injection molding cost per kg? often arises in discussions about manufacturing budgets. Generally, the cost can range from $2 to $5 per kilogram depending on factors like material type and complexity of the mold design. It's essential to note that this pricing can fluctuate based on market conditions, including resin prices and labor rates, impacting the overall injection molding price.

When considering how much does an injection mold cost in terms of weight, remember that heavier parts typically incur higher costs due to increased material usage and longer cycle times. Additionally, custom designs may elevate these figures further, so precise calculations are vital for accurate budgeting. Ultimately, understanding these dynamics helps businesses gauge their expected expenses effectively.

Volume Pricing and Its Effects

Volume pricing plays a significant role in determining how much injection molding costs overall. As production volumes increase, manufacturers often benefit from lower per-kilogram prices due to economies of scale—essentially getting more bang for their buck as they produce larger quantities. This is particularly relevant when assessing how much does injection molding cost in China compared to other regions where labor and materials may be pricier.

For instance, companies like PCBWay offer competitive pricing models that reward larger orders with reduced rates per kg. Therefore, it’s wise for businesses to consider their projected production volumes when negotiating contracts or calculating total expenses for an injection mold project. In doing so, they can maximize savings while ensuring product availability meets market demands.

Managing Costs for Large Production Runs

Managing costs effectively during large production runs is crucial for maintaining profitability in any manufacturing operation involving injection molding machines. Companies must carefully assess all associated expenses—material costs, labor rates, overheads—to achieve a comprehensive understanding of the total investment required for each run. Knowing how to calculate injection mold cost accurately will help streamline this process significantly.

Additionally, leveraging technology such as advanced software tools can provide insights into potential savings during large-scale projects by analyzing historical data and predicting future trends in pricing structures. This proactive approach allows manufacturers not only to control current spending but also plan strategically for future projects based on fluctuating market conditions affecting the cost of injection molding machine operations and materials used.

Ultimately, keeping a close eye on these factors ensures businesses remain competitive while producing high-quality products at favorable prices without sacrificing efficiency or effectiveness.

Calculating Injection Mold Costs

Understanding how to calculate injection mold costs is crucial for any business looking to optimize their production process. The cost of injection molding can vary significantly based on several factors, including the complexity of the part, material selection, and production volume. So, how much does an injection mold cost? Let’s dive into the nitty-gritty.

How to Calculate Injection Mold Cost?

To determine the total cost of an injection mold, you need to consider several key elements: tooling costs, material expenses, and labor rates. Tooling costs typically account for a significant portion of the overall injection molding price; this includes design and fabrication of the mold itself. Additionally, understanding how much does injection molding cost in China can help you compare these expenses against domestic manufacturing options.

When calculating your mold cost, factor in not just initial expenses but also ongoing maintenance and potential modifications over time. This comprehensive approach ensures that you have a realistic view of your long-term investment in injection molding capabilities. Ultimately, accurate calculations will empower you to make informed decisions about production runs and budget allocations.

Tools and Software for Cost Estimation

In today's digital age, there are numerous tools and software programs designed specifically for estimating costs associated with injection molding projects. These resources can streamline your budgeting process by providing estimates based on input variables like part geometry and material type. Popular software options often include advanced features that allow users to simulate different scenarios—making it easier to grasp how much does injection molding cost per kg or per unit.

Many manufacturers also offer online calculators tailored to specific needs; simply input your project details and receive instant estimates for both tooling costs and production expenses. Utilizing these tools not only saves time but also enhances accuracy when determining overall project viability—especially when considering factors like the cost of an injection molding machine or changes in material prices over time.

Tips for Accurate Budgeting

Accurate budgeting is essential when working with injection molds; unexpected costs can derail even the best-laid plans if you're not prepared! One effective strategy is conducting thorough market research on current pricing trends—including insights into PCBWay injection molding price points—to gauge where your project stands relative to industry standards.

Additionally, it's wise to include a contingency fund within your budget; this helps cover unforeseen expenses that may arise during production or post-production phases. Finally, regularly reviewing your budget against actual expenditures allows you to adjust future projects more accurately—ensuring you remain competitive while keeping an eye on profitability.

Conclusion

In conclusion, understanding the various factors that influence injection molding costs is crucial for businesses looking to optimize their production processes. The injection molding price can vary significantly depending on materials, labor, tooling, and regional manufacturing capabilities. By being informed about these elements, companies can make strategic decisions that enhance cost efficiency while maintaining product quality.

Strategies for Reducing Injection Molding Costs

To effectively reduce injection molding costs, companies should start by analyzing their material choices and exploring alternatives that may offer better pricing without compromising quality. Additionally, optimizing the design of parts can lead to decreased tooling costs and improved production efficiency. Regularly reviewing supplier contracts and negotiating better terms can also play a significant role in lowering the overall cost of injection molding.

The Role of Technology in Cost Efficiency

Technology plays an increasingly vital role in enhancing cost efficiency within the injection molding industry. Advanced software tools allow manufacturers to calculate injection mold costs more accurately and forecast expenses associated with each production run. Furthermore, automation in manufacturing processes can significantly decrease labor costs while improving precision—ultimately leading to a more favorable injection molding price.

Working with Experts like Baoyuan for Success

Partnering with experienced professionals like Baoyuan can provide invaluable insights into how much does an injection mold cost? Their expertise extends beyond just pricing; they understand the nuances of global manufacturing landscapes—including how much does injection molding cost in China? Collaborating with experts ensures you not only get competitive PCBWay injection molding prices but also receive guidance on best practices for managing your overall production budget.