Introduction

In the ever-evolving world of healthcare, the manufacturing of medical devices plays a crucial role. At the heart of this process lies medical plastic injection molding, a method that ensures precision and efficiency in creating essential components. Selecting the right medical plastic injection molding producer is vital, as it directly impacts product quality, compliance with regulations, and ultimately patient safety.

Understanding Medical Plastic Injection Molding

Medical plastic injection molding is a specialized process that involves shaping molten plastic into desired forms through a mold. This technique is particularly important for producing intricate and high-quality parts required in the medical field, such as syringes, surgical instruments, and various other critical components. Companies involved in medical injection molding must adhere to stringent guidelines to ensure that their products meet industry standards and safety requirements.

Importance of Choosing the Right Producer

Choosing the right medical injection molding company can be a game changer for your project’s success. A reliable producer not only guarantees quality but also brings expertise in navigating regulatory landscapes that govern medical device production. Partnering with an established producer can lead to better outcomes in terms of innovation, efficiency, and cost-effectiveness.

Key Factors to Consider

When evaluating potential medical plastic injection molding companies, several key factors come into play. First and foremost is industry experience; understanding how long a company has been operating gives insight into its reliability and capabilities. Additionally, quality assurance practices are paramount; you’ll want to ensure that any producer you consider maintains high standards throughout their manufacturing processes—after all, we’re talking about products that impact lives!

Industry Experience

Evaluating Company History

Evaluating the company history of potential medical plastic injection molding producers is essential for making an informed decision. Look for companies that have established themselves over several years, demonstrating stability and resilience in an ever-evolving industry. A rich history often correlates with accumulated knowledge and expertise in producing high-quality medical device injection molding solutions.

Additionally, consider how these companies have adapted to technological advancements and regulatory changes within the sector. This adaptability not only showcases their commitment to growth but also indicates their ability to deliver Injection Molded Parts for Medical & Pharmaceutical applications that meet stringent standards. Ultimately, a thorough evaluation of a company's history will reveal whether they are equipped to handle your specific needs.

Importance of Proven Track Record

A proven track record is vital when selecting among various medical injection molding companies because it reflects both reliability and quality assurance. Companies with successful past projects can demonstrate their capability to produce consistent results while adhering to regulatory requirements specific to the healthcare industry. This track record acts as a safety net; knowing other clients have successfully partnered with them provides peace of mind.

Moreover, proven success stories often translate into innovation within production processes—something crucial for meeting the demanding standards of medical device injection molding. You want a producer who has not only delivered on promises but has also evolved with market needs over time. When looking at potential partners, ask about their previous projects; if they’ve tackled complex challenges successfully before, chances are they’ll do it again for you.

Case Studies of Leading Producers

Examining case studies from leading producers in the field can offer invaluable insights into what makes them stand out among other medical plastic injection molding producers. For instance, Ensinger Injection Molding has carved out its niche by focusing on high-performance polymers tailored specifically for medical applications. Their case studies highlight successful collaborations that resulted in innovative solutions while maintaining compliance with regulatory standards.

Another noteworthy example involves Baoyuan's work with major hospitals where they provided customized solutions that enhanced operational efficiency through tailored Injection Molded Parts for Medical & Pharmaceutical use cases. These real-world applications showcase how experienced producers navigate complex project demands while ensuring product integrity and safety—key factors when choosing your partner in this critical industry.

In summary, diving deep into industry experience—including evaluating company history, understanding the importance of proven track records, and reviewing relevant case studies—will empower you to select the right medical plastic injection molding producer for your needs.

Quality Assurance Practices

Standards and Certifications

In the realm of medical injection molding, adherence to industry standards is non-negotiable. Certification from recognized bodies such as ISO 13485 demonstrates that a company has established an effective quality management system specifically for medical devices. Medical injection molding companies that hold these certifications not only enhance their credibility but also reassure clients about their commitment to delivering safe, reliable products.

Moreover, compliance with regulations such as FDA guidelines is crucial for any producer involved in Medical Device Injection Molding. These certifications often involve regular audits and assessments, ensuring continuous improvement in processes and products. When evaluating potential partners for injection molded parts for medical & pharmaceutical applications, checking their standards and certifications should be at the top of your list.

Role of Quality Control in Medical Products

Quality control plays a pivotal role in ensuring that every batch of products meets predetermined specifications before reaching the market. In the context of medical plastic injection molding, this means rigorous testing at various stages—from raw material selection to final product inspection. A thorough quality control process helps identify defects early on, minimizing risks associated with faulty products.

The implications of inadequate quality control can be severe; they range from regulatory penalties to catastrophic failures in critical healthcare settings. Thus, understanding how a potential partner manages its quality control processes is essential when selecting among various Medical injection molding companies. By prioritizing those with robust QC measures, you ensure that your projects will yield reliable results time after time.

Spotlight on Baoyuan's Quality Assurance

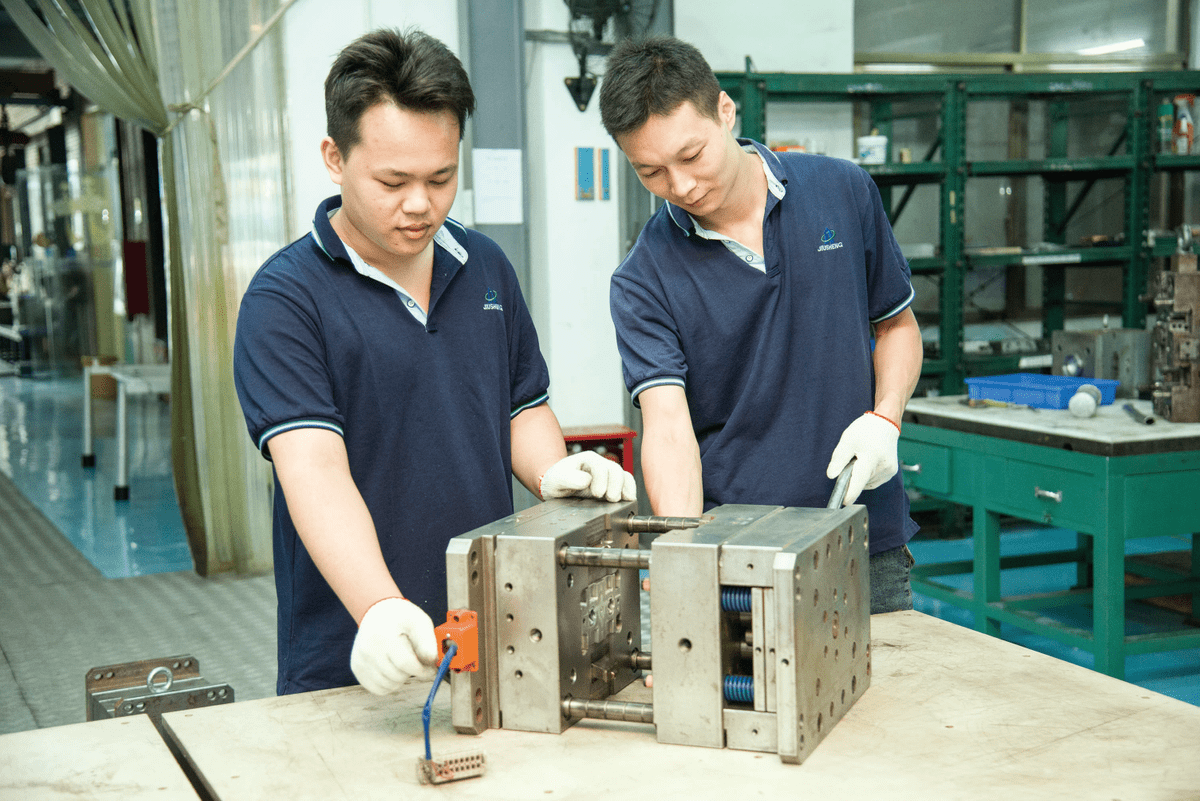

Baoyuan stands out among other medical plastic injection molding producers due to its uncompromising approach to quality assurance practices. The company boasts multiple industry-standard certifications that validate its commitment to excellence in Medical Device Injection Molding processes. By integrating advanced technology into their production lines and adhering strictly to regulatory requirements, Baoyuan ensures that every component meets or exceeds expectations.

What sets Baoyuan apart is its proactive stance on maintaining high-quality standards through continuous training programs for staff and regular audits of production processes. Their comprehensive approach means they don’t just meet minimum requirements; they strive for excellence at every stage—from design through delivery of injection molded parts for medical & pharmaceutical uses. Choosing Baoyuan as your partner means aligning with a producer who genuinely prioritizes safety and quality above all else.

Technical Expertise

In the realm of medical plastic injection molding, technical expertise is not just a luxury; it’s a necessity. The complexity of medical device production demands manufacturers who possess advanced engineering skills, as these capabilities directly influence the quality and precision of the final products. A proficient medical plastic injection molding producer can navigate intricate design requirements and ensure that every molded part meets stringent industry standards.

Significance of Advanced Engineering Skills

Advanced engineering skills are crucial for any successful medical injection molding company, especially when it comes to creating intricate designs that are often required in the healthcare sector. These skills help in optimizing processes and minimizing errors during production, which is vital for maintaining compliance with regulatory standards. Companies like Ensinger injection molding have established themselves by employing highly skilled engineers who understand both the technical and regulatory landscapes of medical device manufacturing.

The ability to innovate while adhering to strict guidelines sets apart top-tier medical injection molding companies from their competitors. Engineers must be adept at problem-solving, able to foresee potential issues before they arise during the production process. This foresight not only saves time but also significantly reduces costs associated with rework or product recalls.

The Role of Software in Design and Production

Software plays an integral role in modern medical device injection molding processes, streamlining everything from initial design to final production stages. Advanced software tools facilitate precise modeling and simulation, allowing engineers to visualize how their designs will perform under various conditions before physical prototypes are created. This capability is particularly beneficial for producing Injection Molded Parts for Medical & Pharmaceutical applications where accuracy is paramount.

Moreover, software aids in automating various aspects of production, enhancing efficiency while minimizing human error—an essential factor in maintaining quality control within this highly regulated industry. With robust software systems in place, a medical plastic injection molding producer can effectively manage complex projects that involve multiple stakeholders and intricate timelines.

How Baoyuan Leverages Technical Knowledge

Baoyuan stands out among leading medical injection molding companies due to its commitment to leveraging technical knowledge at every stage of its operations. By combining advanced engineering skills with state-of-the-art software solutions, Baoyuan ensures that its products meet or exceed industry standards for safety and efficacy. Their team continuously invests in training and development programs to keep pace with evolving technologies and practices within the field.

Additionally, Baoyuan's focus on collaboration between departments enhances innovation while ensuring seamless communication throughout the project lifecycle—from concept through delivery of Injection Molded Parts for Medical & Pharmaceutical needs. This holistic approach not only solidifies their reputation as a reliable partner but also helps clients achieve their goals efficiently and effectively.

Production Capacity and Flexibility

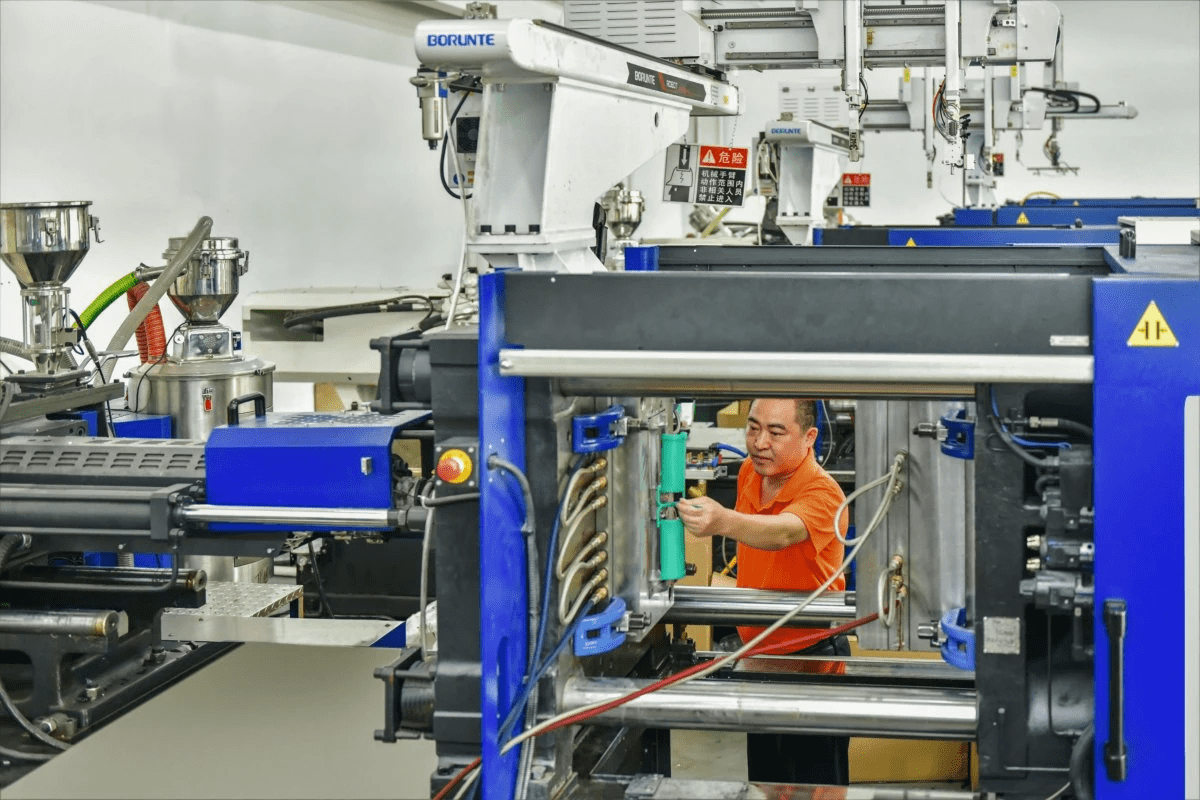

In the fast-paced world of medical plastic injection molding, production capacity and flexibility are paramount. A capable medical plastic injection molding producer must not only meet current demands but also adapt to future needs. This adaptability ensures that clients receive timely deliveries without compromising on quality, a critical factor in the medical device industry.

Understanding Production Scalability

Production scalability is essential for any medical injection molding company aiming to thrive in a competitive market. It refers to the ability to increase or decrease production levels based on demand, which is particularly important for projects that may require rapid scaling up or down due to regulatory changes or market fluctuations. A producer with robust scalability can handle everything from small batch runs of specialized components to large-scale production of injection molded parts for medical and pharmaceutical applications.

Customization Options for Medical Needs

Customization is often a key requirement when selecting a medical device injection molding partner. Each project may have unique specifications, from material selection to dimensions and design intricacies that cater specifically to medical applications. Leading companies in the field, including those specializing in Ensinger injection molding, offer tailored solutions that address these specific needs while ensuring compliance with stringent industry standards.

Examining Baoyuan’s Capability

When evaluating Baoyuan as a potential partner, it’s crucial to consider their production capacity and flexibility within the realm of medical plastic injection molding. Baoyuan has demonstrated an impressive ability to scale operations efficiently while providing customization options tailored specifically for the healthcare sector. Their state-of-the-art facilities and experienced team ensure they can deliver high-quality products consistently, making them a formidable choice among leading medical injection molding companies.

Cost Considerations

Balancing Quality and Affordability

Finding the sweet spot between quality and affordability can feel like navigating a minefield in the world of medical injection molding companies. While it's tempting to go for lower prices, remember that the materials and processes used directly impact product safety and efficacy. A reputable medical plastic injection molding producer will provide transparent pricing structures that reflect their commitment to quality without breaking your budget.

Hidden Costs to Watch Out For

Hidden costs can sneak up on you like an unexpected bill after a night out; they can turn what seemed like an affordable deal into a financial headache. When evaluating potential medical injection molding producers, be sure to inquire about additional fees that may not be immediately apparent—think tooling costs, design modifications, or shipping expenses. Understanding these potential pitfalls ensures you won’t be blindsided later on when you're knee-deep in production of your injection molded parts for medical & pharmaceutical applications.

Value Proposition of Top Producers

Top-tier medical plastic injection molding companies offer more than just competitive pricing; they provide value through reliability, expertise, and innovation. By investing in advanced technologies and skilled professionals, these producers ensure high-quality outcomes while maintaining reasonable costs over time. For instance, Ensinger injection molding stands out by delivering exceptional precision and durability in their products—an investment well worth considering for those serious about their medical device injection molding needs.

Conclusion

In the world of medical plastic injection molding, making an informed decision is crucial for the success of your projects. The right medical plastic injection molding producer can significantly impact not only the quality of your products but also their market viability. By carefully considering factors such as industry experience, quality assurance practices, and technical expertise, you can select a partner that aligns with your vision and operational needs.

Making an Informed Decision

When it comes to choosing a medical injection molding company, knowledge is power. Delve into their history and track record; after all, experience counts in a field where precision and compliance are paramount. A thorough evaluation will help you avoid pitfalls and ensure that you're working with a credible producer who understands the intricacies of medical device injection molding.

The Long-Term Impact of Your Choice

Your choice of a medical plastic injection molding producer will have lasting implications on product quality and business reputation. Selecting a reliable partner can lead to consistent production of high-quality injection molded parts for medical & pharmaceutical applications, fostering trust among stakeholders and consumers alike. Conversely, opting for subpar producers may result in costly recalls or compliance issues down the line—an outcome no one wants to face.

Next Steps in Partnering with a Producer

Once you've narrowed down your options among various medical injection molding companies, it's time to take actionable steps toward partnership. Initiate discussions with potential producers about their capabilities in Ensinger injection molding or other specialized techniques relevant to your needs. Finally, consider conducting site visits or requesting samples to ensure that the producer's offerings align perfectly with your project's requirements.