Introduction

Plastic processing is a complex and intricate field that requires a deep understanding of efficient strategies to ensure optimal production. From selecting the right materials to implementing sustainable practices, the challenges in plastic processing are numerous. This is where Baoyuan shines as a leader in plastic processing techniques, offering innovative solutions and cutting-edge technology to streamline the entire process.

Understanding Efficient Plastic Processing Strategies

Efficient plastic processing strategies are essential for achieving high-quality results while maximizing productivity. Whether it's optimizing injection molding techniques or streamlining mold design and manufacturing, the key lies in finding the most effective methods for each stage of production.

Overcoming Challenges in Plastic Processing

From material selection to waste management, plastic processing presents a myriad of challenges that require careful navigation. Selecting the ideal plastic resins such as ABS, Polycarbonate (PC), Polyoxymethylene (POM), Polyvinyl chloride (PVC), Plexiglas (PMMA), and High-Density Polyethylene (HDPE) is crucial for ensuring the success of any plastic processing project.

Baoyuan: A Leader in Plastic Processing Techniques

Baoyuan has established itself as a trailblazer in the field of plastic processing, offering expertise in material choice, injection molding solutions, mold design software, sustainable production practices, and quality control measures. Their commitment to excellence sets them apart as an industry leader.

Choosing the Right Materials

When it comes to plastic processing, selecting the ideal plastic resins is crucial for achieving the desired product characteristics. ABS plastic, Polycarbonate (PC), Polyoxymethylene (POM), Polyvinyl chloride (PVC), Plexiglas (PMMA), and High-Density Polyethylene (HDPE) are some of the most commonly used materials for plastic processing. Each material has its own unique properties and applications, making it essential to carefully consider which one will best suit the specific requirements of a project.

Selecting the Ideal Plastic Resins

ABS plastic is known for its excellent impact resistance and toughness, making it a popular choice for products that require durability. Polycarbonate (PC) offers high heat resistance and transparency, making it suitable for applications such as safety goggles and electronic components. Polyoxymethylene (POM) is valued for its low friction and high stiffness, making it an ideal choice for precision parts in mechanical systems.

When selecting the ideal plastic resins, it is important to consider the specific requirements of the product in terms of durability, heat resistance, transparency, friction, and stiffness. ABS plastic is a popular choice for products that require impact resistance and toughness, making it suitable for items such as protective cases and automotive parts. On the other hand, polycarbonate (PC) is well-suited for applications where high heat resistance and transparency are essential, such as in safety goggles and electronic components. Meanwhile, polyoxymethylene (POM) stands out for its low friction and high stiffness, making it an ideal choice for precision parts in mechanical systems where minimal wear and precise movement are crucial.

Factors to Consider in Material Selection

When choosing materials for plastic processing, factors such as mechanical properties, chemical resistance, thermal stability, and cost must be taken into account. It's important to consider the specific requirements of the end product in order to select a material that will meet those needs effectively. Additionally, environmental impact and recyclability are becoming increasingly important considerations in material selection. Choosing materials that are eco-friendly and sustainable can enhance the overall appeal of the end product while also aligning with corporate social responsibility goals. Furthermore, ease of processing and compatibility with existing manufacturing equipment should also be factored in to ensure smooth production processes and efficient use of resources.

Baoyuan's Expertise in Material Choice

Baoyuan has extensive expertise in material selection for plastic processing projects. With a deep understanding of the properties and characteristics of various plastic resins, Baoyuan can provide valuable insights into choosing the right materials to achieve optimal results in terms of performance, cost-effectiveness, and sustainability.

Baoyuan's expertise in material choice extends beyond just selecting the right resin for a project. With a keen eye for detail and a thorough understanding of the manufacturing process, Baoyuan can also optimize injection molding techniques to ensure the highest quality and consistency in the final products. By fine-tuning parameters such as temperature, pressure, and cooling time, Baoyuan can help minimize defects and reduce production costs, ultimately leading to greater efficiency and competitiveness in the market.

Optimizing Injection Molding Techniques

Enhancing Efficiency in Injection Molding

When it comes to plastic processing, efficiency is key. Baoyuan specializes in enhancing efficiency in injection molding through the use of advanced machinery and streamlined production processes. By optimizing cycle times and minimizing material waste, Baoyuan ensures that the injection molding process is as cost-effective as possible.

By implementing cutting-edge technology and automation, Baoyuan is able to reduce human error and increase the precision of injection molding processes. This not only improves the quality of the final products but also minimizes the need for rework or corrections, saving time and resources in the long run. With state-of-the-art machinery and software, Baoyuan is at the forefront of injection molding innovation.

Baoyuan's Innovative Injection Molding Solutions

Baoyuan offers innovative solutions for injection molding, catering to a wide range of industries and product requirements. With expertise in working with various materials for plastic processing such as ABS plastic, Polycarbonate (PC), Polyoxymethylene (POM), Polyvinyl chloride (PVC), Plexiglas (PMMA), and High-Density Polyethylene (HDPE), Baoyuan can customize injection molding techniques to meet specific project needs.

In addition to its expertise in working with various materials, Baoyuan also utilizes cutting-edge technology to enhance its injection molding solutions. By incorporating advanced machinery and software, Baoyuan is able to achieve higher precision, faster production speeds, and overall improved quality in the finished products. This commitment to staying at the forefront of technological advancements ensures that clients receive the most efficient and effective injection molding solutions for their specific needs.

The Role of Technology in Injection Molding

Technology plays a crucial role in modern injection molding techniques, and Baoyuan stays ahead of the curve by leveraging cutting-edge equipment and software. From computer-aided design (CAD) tools for mold creation to real-time monitoring systems for quality control, technology is integrated into every step of the injection molding process at Baoyuan.

Streamlining Mold Design and Manufacturing

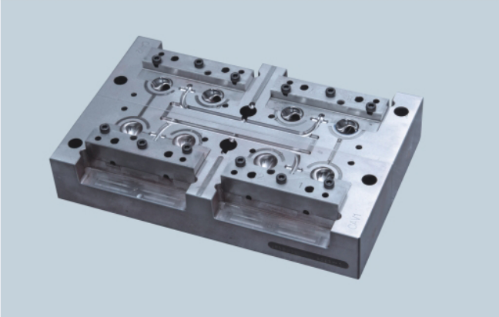

Baoyuan's Advanced Mold Design Software utilizes cutting-edge technology to create precise and efficient mold designs for plastic processing. This software allows for intricate detailing and customization, ensuring that molds are tailored to the specific requirements of each project. With a user-friendly interface, it enables seamless collaboration between design teams and production units, resulting in streamlined mold development processes.

Baoyuan's Advanced Mold Design Software

The advanced mold design software utilized by Baoyuan is equipped with a wide range of features that cater to various plastic processing needs. From complex geometries to intricate parting lines, this software can handle it all with ease, providing unparalleled flexibility in mold design. Its compatibility with a diverse range of materials for plastic processing, such as ABS plastic, Polycarbonate (PC), Polyoxymethylene (POM), Polyvinyl chloride (PVC), Plexiglas (PMMA), and High-Density Polyethylene (HDPE), ensures that the optimal material is selected for each project.

Precision Mold Opening and Closing Techniques

In addition to advanced mold design software, Baoyuan employs precision mold opening and closing techniques to ensure seamless production processes. By fine-tuning the movements of molds during the injection molding process, they minimize wear and tear on equipment while maximizing productivity. This attention to detail results in consistent part quality and reduced downtime due to maintenance or repairs.

Ensuring Quality Assurance in Mold Manufacturing

Baoyuan places great emphasis on quality assurance throughout the mold manufacturing process. From material selection to final inspection, every step is meticulously monitored to maintain high standards of precision and durability in the molds produced. Rigorous testing procedures are implemented to validate the structural integrity and performance of each mold before it is put into operation, guaranteeing reliable results in plastic processing.

Implementing Sustainable Production Practices

Baoyuan's Commitment to Sustainable Plastic Processing

Baoyuan is dedicated to sustainable plastic processing, striving to minimize environmental impact while maximizing efficiency. By utilizing cutting-edge technology and eco-friendly materials, Baoyuan ensures that their plastic processing techniques are both environmentally responsible and economically viable.

Green Initiatives in Plastic Manufacturing

In line with their commitment to sustainability, Baoyuan has implemented various green initiatives in their plastic manufacturing processes. From utilizing recyclable and biodegradable materials like ABS plastic and High-Density Polyethylene (HDPE) to reducing energy consumption through innovative production methods, Baoyuan is at the forefront of environmentally conscious plastic manufacturing.

Efficient Waste Management Strategies

Baoyuan has also developed efficient waste management strategies to minimize the environmental impact of their plastic processing operations. Through the implementation of recycling programs and waste reduction measures, Baoyuan ensures that any waste generated during production is handled responsibly and sustainably.

Now that we have explored Baoyuan's commitment to sustainable production practices in plastic processing, let's delve into their rigorous quality control measures in the next section.

Quality Control and Assurance

In the competitive world of plastic processing, Baoyuan stands out for its rigorous quality control measures. Every step of the production process is closely monitored to ensure that only the highest quality materials are used. This commitment to excellence is evident in the consistent performance of ABS plastic, Polycarbonate (PC), and Polyoxymethylene (POM) products.

Baoyuan's Rigorous Quality Control Measures

Baoyuan's state-of-the-art facilities are equipped with advanced technology to conduct thorough quality checks at every stage of plastic processing. From raw material inspection to final product testing, their quality control measures leave no room for error. This meticulous attention to detail guarantees that only top-notch materials like Polyvinyl chloride (PVC), Plexiglas (PMMA), and High-Density Polyethylene (HDPE) are used in production.

Ensuring Consistency in Plastic Product Quality

Consistency is key in plastic product manufacturing, and Baoyuan excels in maintaining uniformity across its range of offerings. By adhering to strict quality standards and implementing stringent testing protocols, they ensure that each batch of products meets the same high standards as the last. This unwavering commitment to consistency sets them apart as a trusted provider of reliable plastic solutions.

Importance of Quality Assurance in Plastic Processing

Quality assurance is paramount in plastic processing, as it directly impacts product performance and customer satisfaction. With Baoyuan's emphasis on quality control and assurance, clients can have full confidence in the durability and reliability of their plastic products. By prioritizing excellence at every stage, Baoyuan reinforces the importance of maintaining high standards in the industry.

Conclusion

Achieving Operational Excellence in Plastic Processing

In conclusion, achieving operational excellence in plastic processing requires a combination of efficient material selection, innovative manufacturing techniques, and a commitment to sustainability. Baoyuan's expertise in plastic processing has set the standard for operational excellence in the industry, ensuring high-quality products and minimal waste.

Baoyuan's commitment to sustainability is evident in their innovative approach to plastic manufacturing. By utilizing eco-friendly materials and implementing energy-efficient production processes, they have significantly reduced their environmental impact. This dedication to sustainability not only benefits the planet but also aligns with the growing consumer demand for environmentally responsible products. As a result, Baoyuan has solidified its position as a leader in operational excellence within the plastic processing industry.

Baoyuan's Ongoing Innovations in Plastic Manufacturing

Baoyuan continues to lead the way in plastic manufacturing through ongoing innovations in injection molding, mold design, and sustainable production practices. With a focus on advanced technology and continuous improvement, Baoyuan remains at the forefront of the industry, delivering cutting-edge solutions for efficient plastic processing.

With a commitment to staying ahead of the curve, Baoyuan invests in cutting-edge technology to enhance its injection molding processes. By incorporating the latest equipment and software, Baoyuan ensures precision, speed, and quality in every plastic product it manufactures. This dedication to innovation allows Baoyuan to meet the evolving demands of the industry and provide customers with efficient and reliable solutions.

The Future of Efficient Plastic Processing

As the demand for sustainable and high-quality plastic products continues to grow, the future of efficient plastic processing lies in advanced materials, streamlined production techniques, and a focus on environmental responsibility. Baoyuan is poised to drive this future with its dedication to innovation and excellence. By investing in research and development, Baoyuan is constantly exploring new materials that are both durable and eco-friendly, reducing the environmental impact of plastic production. Additionally, the implementation of cutting-edge production techniques allows for greater efficiency and precision in manufacturing processes, leading to higher quality end products while minimizing waste.