Introduction

When it comes to manufacturing car parts, Automotive Injection Molding plays a crucial role in creating high-quality, durable components. At Baoyuan, our team's expertise lies in understanding the intricate process of molding car parts to meet the demanding standards of the automotive industry. The importance of efficient molding in car parts cannot be overstated, as it directly impacts the performance and safety of vehicles on the road.

Understanding Automotive Injection Molding

Automotive Injection Molding is a manufacturing process that involves injecting molten material into a mold cavity to create car components with precision and consistency. This method offers key benefits such as cost-effectiveness, fast production cycles, and the ability to produce complex shapes and designs for various car parts.

The Baoyuan Team Expertise

At Baoyuan, our team brings years of experience and technical know-how in Plastic Automotive Mold Design & Manufacturing. We understand the intricacies of mold design and have an innovative approach that ensures efficient production and quality assurance for all our clients' needs.

Importance of Efficient Molding in Car Parts

Efficient molding is critical in ensuring that car components meet stringent performance and safety standards. From interior trims to exterior body panels, every detail matters when it comes to molding car parts that are durable, lightweight, and aesthetically appealing.

What is Automotive Injection Molding?

Automotive Injection Molding is a manufacturing process used to produce parts by injecting molten material into a mold. This process allows for the production of complex, high-quality, and cost-effective car components. The molten material is injected at high pressure into a mold cavity, where it cools and hardens to the configuration of the cavity.

Process Overview

The process begins with the melting of the plastic material, which is then injected into a mold under high pressure. Once inside the mold, the material takes on the shape of the cavity and cools to form the desired part. This method allows for intricate designs and precise dimensions in molding car parts, making it an ideal choice for automotive applications.

Additionally, the injection molding process allows for a high level of consistency and repeatability in producing car parts. This means that automotive manufacturers can rely on the same quality and performance in every part, leading to greater efficiency and cost savings in the production process. The ability to create complex shapes and features also opens up new possibilities for innovative car designs, giving automakers a competitive edge in the market.

Key Benefits

One of the key benefits of Automotive Injection Molding is its ability to produce large volumes of parts with high precision and consistency. It also enables cost-effective production due to reduced waste and faster cycle times. Additionally, this process offers design flexibility, allowing for complex geometries and efficient use of materials.

Furthermore, Automotive Injection Molding allows for the integration of multiple parts into a single component, reducing the need for assembly and minimizing potential points of failure. This results in improved product durability and reliability, which are crucial factors in car manufacturing. The ability to create intricate and functional parts in large quantities also makes this process ideal for producing components such as air intake manifolds, dashboards, and door panels with consistent quality.

Applications in Car Manufacturing

Automotive Injection Molding is widely used in car manufacturing for producing various components such as bumpers, dashboards, interior panels, door handles, and many more. The process's ability to create lightweight yet durable parts makes it an essential technique in modern automotive production.

One of the key advantages of automotive injection molding is its ability to produce complex shapes and designs with high precision and consistency. This makes it possible to create intricate parts that are essential for modern car designs, such as air vents, cup holders, and storage compartments. The versatility of this manufacturing process allows car manufacturers to meet the demands of consumers who value both functionality and aesthetics in their vehicles.

By incorporating these key points about Automotive Injection Molding into your content strategy you can effectively educate your audience about this crucial aspect of car manufacturing while showcasing Baoyuan's expertise in this field.

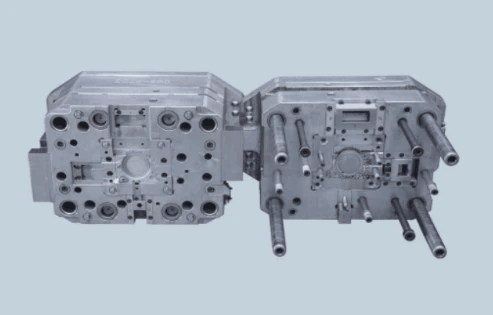

Plastic Automotive Mold Design & Manufacturing

Automotive Injection Molding plays a crucial role in the production of car parts, and the design and manufacturing of plastic automotive molds are essential factors to consider. The molds must be able to withstand high temperatures and pressures, while also being durable enough for long-term use in the manufacturing process.

Factors to Consider

When designing and manufacturing plastic automotive molds for molding car parts, several factors must be taken into account. These include the type of material being used, the complexity of the part, and the expected production volume. Baoyuan's team carefully considers these factors to ensure that the molds meet the specific requirements of each project.

Baoyuan's Innovative Approach

Baoyuan takes an innovative approach to plastic automotive mold design and manufacturing by utilizing advanced technologies and state-of-the-art equipment. This allows for precise and efficient mold production, resulting in high-quality car parts that meet industry standards.

Furthermore, Baoyuan's commitment to quality assurance in mold design ensures that every car part produced meets the highest standards. By implementing rigorous testing and inspection processes, Baoyuan guarantees that each mold is free from defects and capable of producing parts with precise dimensions and smooth finishes. This dedication to excellence sets Baoyuan apart in the automotive mold manufacturing industry, earning the trust of leading car manufacturers worldwide.

Quality Assurance in Mold Design

Quality assurance is a top priority at Baoyuan, especially when it comes to mold design. Rigorous testing and inspection processes are implemented to ensure that every mold meets strict quality standards before being used in the injection molding process. This commitment to quality not only ensures the durability and reliability of the molds but also leads to cost savings by reducing the need for rework or replacement. By catching any potential issues early in the design phase, Baoyuan is able to deliver high-quality molds that meet or exceed customer expectations.

Injection-molded Car Components

Common Applications

Automotive injection molding is widely used in creating a variety of car components, including bumpers, dashboards, interior trims, and even engine components. This process allows for the production of complex shapes and designs that are crucial for modern car manufacturing.

Automotive injection molding offers several advantages over traditional methods of car component manufacturing. One major benefit is the ability to produce parts with a high level of precision and consistency, resulting in improved quality and reliability. Additionally, this process allows for faster production times, reducing overall manufacturing costs and increasing efficiency. With the capability to create intricate designs and shapes, automotive injection molding is essential for meeting the demands of modern car manufacturing.

Advantages Over Traditional Methods

Compared to traditional methods such as metal fabrication or glass blowing, automotive injection molding offers several advantages. It enables faster production times, lower costs, and greater design flexibility. Additionally, the lightweight nature of plastic parts contributes to improved fuel efficiency in vehicles.

Furthermore, automotive injection molding allows for the creation of more complex and intricate parts that would be difficult or impossible to produce using traditional methods. This opens up new possibilities for innovative designs and advanced engineering in the automotive industry. The ability to incorporate multiple materials into a single part also adds to the versatility of injection molding, providing even more options for creating high-performance components.

Baoyuan's Specialization in Complex Parts

Baoyuan excels in producing intricate and complex injection-molded car components that require high precision and quality. From intricate interior panels to durable exterior parts, Baoyuan's expertise ensures that every component meets the rigorous standards of the automotive industry.

Baoyuan's specialization in complex parts extends beyond just the manufacturing process. Their team of engineers and designers work closely with clients to understand their specific needs and requirements, ensuring that every component is not only precise and high-quality but also tailored to the unique specifications of each car model. This level of customization sets Baoyuan apart in the industry, as they are able to deliver components that seamlessly integrate into the overall design and functionality of the vehicle.

Efficient Production and Quality Assurance

Automotive Injection Molding is a complex process that requires expertise and precision. Baoyuan's senior management team boasts years of experience in the industry, ensuring efficient production and quality assurance for molding car parts. Their technical expertise allows for innovative solutions to any molding challenges, guaranteeing top-notch results.

Baoyuan's Senior Management and Technical Expertise

Baoyuan's team of senior managers and technical experts are well-versed in the intricacies of Automotive Injection Molding. With a deep understanding of mold design, manufacturing, and production processes, they oversee every aspect of the operation to ensure optimal results. Their expertise is a key factor in delivering high-quality, durable car parts through efficient molding techniques.

Software Utilization for Molding Process

In the modern automotive industry, technology plays a crucial role in enhancing efficiency and precision in the molding process. Baoyuan leverages cutting-edge software to streamline mold design and manufacturing, reducing lead times and minimizing errors. This approach not only speeds up production but also ensures that each part meets the highest standards of quality.

Single-color and Double-color Plastic Products

Molding car parts often involves creating single-color or double-color plastic products with intricate designs. Baoyuan specializes in producing these complex components with utmost precision, offering a wide range of options for automotive applications. Whether it's a simple bumper or a multi-functional dashboard panel, Baoyuan excels in delivering high-quality single-color and double-color plastic products tailored to specific requirements.

Conclusion

Automotive Injection Molding plays a crucial role in producing high-quality car parts, and Baoyuan's expertise in Plastic Automotive Mold Design & Manufacturing has revolutionized the industry. The future of molding in the automotive industry is bright, with advancements in technology and materials paving the way for more efficient and sustainable production processes.

Key Considerations for Molding Car Parts

When it comes to molding car parts, precision and durability are key considerations. The molding process in automotive requires meticulous attention to detail to ensure that each component meets the highest standards of quality and performance. Baoyuan's dedication to excellence in mold design and manufacturing sets a new benchmark for the industry.

Baoyuan's Role in Advancing Automotive Injection Molding

Baoyuan's commitment to innovation and continuous improvement has positioned them as leaders in advancing Automotive Injection Molding. Their specialized knowledge and cutting-edge technology enable them to produce complex injection-molded car components with unmatched efficiency and precision, setting new standards for the industry.

Future of Molding in Automotive Industry

The future of molding in the automotive industry is poised for remarkable growth, driven by advancements in materials, technology, and design capabilities. As demand for lightweight, durable, and eco-friendly car components continues to rise, injection-molded parts are set to play an increasingly integral role in shaping the vehicles of tomorrow.