Introduction

When it comes to plastic manufacturing, two popular methods are thermoforming and injection molding. Thermoforming involves heating a thermoplastic sheet and shaping it over a mold, while injection molding uses high pressure to inject molten material into a mold. Both processes have their pros and cons, and Baoyuan has extensive expertise in both.

Understanding Thermoforming and Injection Molding

Thermoforming is a cost-effective method for producing large, shallow parts with low tooling costs, while injection molding is ideal for high-volume production of complex, durable parts. Baoyuan's understanding of these methods allows them to offer tailored solutions for various plastic manufacturing needs.

Exploring the Pros and Cons

Thermoforming offers design flexibility and quick production turnaround, but it may have limitations in complexity and durability. On the other hand, injection molding provides precision and consistency but may require higher initial investment costs. Baoyuan's expertise ensures that clients are aware of the trade-offs involved in choosing the right method for their project.

Baoyuan's Expertise in Plastic Manufacturing

Baoyuan specializes in providing custom plastic solutions using advanced thermoforming and injection molding techniques. With a commitment to quality and innovation, they offer comprehensive support from design to production, ensuring that clients receive top-notch plastic products tailored to their specific needs.

Thermoforming vs. Injection Molding

When comparing thermoforming vs. injection molding, it's important to consider the process and cost differences. Thermoforming involves heating a plastic sheet and shaping it over a mold, making it a more cost-effective option for large parts with simple designs. On the other hand, injection molding uses melted plastic injected into a mold, making it ideal for intricate parts but with higher tooling costs.

The Process and Cost Comparison

Thermoforming is advantageous for its lower tooling costs and shorter production time compared to injection molding. This makes it a preferred method for prototypes or small production runs where cost efficiency is crucial. However, injection molding offers higher precision and consistency in part production, which may justify the higher initial investment for complex or high-volume projects.

While thermoforming may be more cost-efficient for prototypes and small production runs, injection molding offers greater design flexibility and material selection. This is because injection molding allows for the use of a wider range of materials, including high-performance engineering polymers, which can result in stronger and more durable parts. Additionally, the design flexibility of injection molding enables the production of complex geometries and intricate details that may not be achievable with thermoforming.

Material Selection and Design Flexibility

Thermoforming allows for greater design flexibility and material selection due to its ability to handle various thicknesses of plastic sheets and different types of thermoplastics. This versatility makes it suitable for creating products with unique shapes or textures that injection molding may struggle to achieve.

Thermoforming's ability to handle various thicknesses of plastic sheets and different types of thermoplastics opens up a world of possibilities for product designers. This means that unique shapes and textures can be achieved, giving companies a competitive edge in the market. With injection molding, there are limitations to the types of designs that can be produced, making thermoforming an attractive option for those looking to push the boundaries of creativity.

Baoyuan's Approach to Thermoforming and Injection Molding

At Baoyuan, we understand the benefits of both thermoforming and injection molding processes, which is why we offer expertise in both methods to provide our clients with tailored solutions that meet their specific project requirements.

Thermoforming offers several advantages, such as lower tooling costs and faster production times, but it also has its disadvantages. One of the main drawbacks of thermoforming is that it is not suitable for producing complex parts with intricate details. This process is better suited for creating simple shapes and designs, which may limit its use in certain projects. Additionally, thermoforming may result in thicker walls and reduced material strength compared to injection molding, which could be a concern for applications requiring high durability.

Disadvantages of Thermoforming

Thermoforming process has certain disadvantages compared to injection molding. One major drawback is the limitations in complexity, as thermoforming is not as suitable for intricate designs and detailed features as injection molding. This can restrict the types of products that can be produced using thermoforming, especially those with complex geometries and fine details.

Another disadvantage of thermoforming is the durability and longevity concerns associated with the process. Thermoformed products may not be as strong or durable as those made through injection molding, making them more susceptible to wear and tear over time. This can be a significant drawback for products that require high levels of strength and structural integrity.

Baoyuan has developed innovative solutions to address these challenges in thermoforming. By leveraging advanced techniques and materials, Baoyuan is able to overcome the limitations in complexity and enhance the durability of thermoformed products, ensuring that they meet high standards of quality and performance.

Now let's move on to explore why injection molding is considered better than vacuum forming.

Advantages of Injection Molding

When comparing thermoforming vs injection molding, one of the key advantages of injection molding is its precision and consistency. With the ability to create intricate and detailed parts with tight tolerances, injection molding offers a level of accuracy that is unmatched by thermoforming. This makes it an ideal choice for products that require high precision and uniformity in every piece.

Precision and Consistency

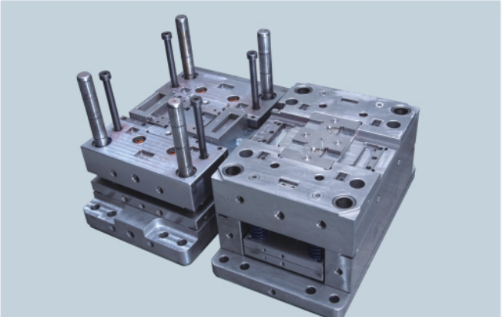

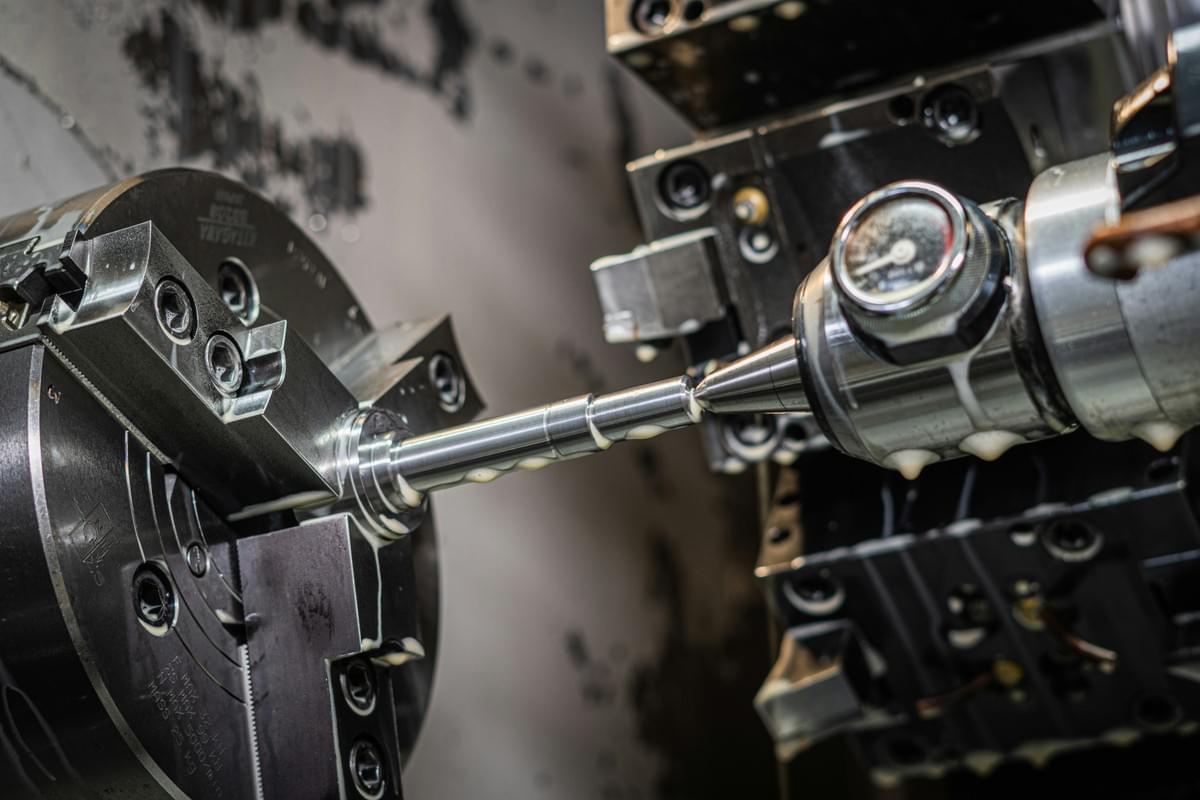

Injection molding excels in producing parts with consistent dimensions and intricate details, making it the preferred method for manufacturing complex components such as gears, medical devices, and electronic enclosures. The process involves injecting molten material into a mold cavity under high pressure, resulting in precise replication of the mold's design with minimal variation between parts.

Strength and Structural Integrity

Another advantage of injection molding over thermoforming is its ability to produce parts with superior strength and structural integrity. The high pressure used in the injection molding process ensures that the material fills every nook and cranny of the mold, resulting in dense, solid parts that exhibit excellent mechanical properties. This makes injection-molded parts ideal for applications where durability and robustness are crucial.

Furthermore, injection molding allows for the use of a wide range of materials, including engineering-grade thermoplastics and even metal. This versatility means that manufacturers can choose the most suitable material for their specific application, further enhancing the strength and structural integrity of the final parts. Additionally, the ability to incorporate features such as ribs, gussets, and other reinforcements during the injection molding process further contributes to the overall robustness of the parts.

Baoyuan's Expertise in Injection Molding Techniques

With decades of experience in plastic manufacturing, Baoyuan has honed its expertise in injection molding techniques to deliver high-quality, precision-engineered plastic components for a wide range of industries. From automotive to consumer electronics, Baoyuan's mastery of injection molding enables them to meet the most demanding requirements with exceptional quality and reliability.

With a keen understanding of the unique requirements of different industries, Baoyuan's injection molding techniques are tailored to deliver precise and customized plastic components. This level of customization allows Baoyuan to meet the specific needs of each client, ensuring that every product is perfectly suited for its intended application. By leveraging their expertise in injection molding, Baoyuan is able to offer cost-effective solutions without compromising on quality or performance.

Difference Between Thermoforming and Injection Molding

Material Behavior and Production Efficiency

When comparing thermoforming vs injection molding, it's important to consider the material behavior and production efficiency. Thermoforming relies on heating a thermoplastic sheet until it becomes pliable, then shaping it over a mold before cooling. This process is less efficient than injection molding, which involves injecting molten plastic into a mold at high pressure for faster production. Baoyuan's expertise in both methods ensures that clients receive the most efficient and cost-effective manufacturing solution for their specific needs.

Environmental Impact and Sustainability

The environmental impact and sustainability of thermoforming vs injection molding is another crucial factor to consider. Thermoforming often generates more waste due to excess material trimmings, while injection molding produces less waste and can use recycled materials for a more sustainable approach. Baoyuan's commitment to sustainable plastic manufacturing includes implementing eco-friendly practices and utilizing recycled materials whenever possible to reduce environmental impact.

Furthermore, Baoyuan is dedicated to exploring innovative ways to minimize waste in thermoforming processes, such as implementing efficient material usage and recycling initiatives. By reducing excess material trimmings and finding creative solutions for waste management, Baoyuan aims to lower its environmental footprint and contribute to a more sustainable plastic manufacturing industry. Additionally, the company is constantly researching and investing in new technologies that align with its commitment to eco-friendly practices, ensuring that its manufacturing processes remain environmentally conscious.

Baoyuan's Commitment to Sustainable Plastic Manufacturing

Baoyuan's dedication to sustainable plastic manufacturing sets them apart in the industry. They prioritize eco-friendly solutions by minimizing waste, reducing energy consumption, and implementing recycling initiatives throughout their manufacturing processes. By choosing Baoyuan as your plastic manufacturing partner, you can be confident in receiving high-quality products that align with your sustainability goals.

Comparing Injection Molding with Vacuum Thermoforming

Speed and Production Volume

When it comes to speed and production volume, injection molding takes the lead. With its ability to create intricate designs at a rapid pace, injection molding is ideal for high-volume production. On the other hand, vacuum thermoforming is better suited for smaller production runs due to its slower cycle times and limited output capacity.

Surface Finish and Detail Accuracy

Injection molding offers superior surface finish and detail accuracy compared to vacuum thermoforming. The precise control over temperature and pressure in injection molding results in smooth, flawless surfaces with intricate details, making it the preferred choice for products requiring a high level of precision.

Baoyuan's Advanced Techniques for Plastic Product Quality

At Baoyuan, we leverage advanced techniques in both injection molding and vacuum thermoforming to ensure top-notch plastic product quality. Our state-of-the-art machinery and skilled technicians enable us to achieve exceptional results in terms of surface finish, detail accuracy, and overall product quality.

Conclusion

Choosing the Right Manufacturing Method for Your Project

When considering thermoforming vs injection molding, it's important to weigh the advantages and disadvantages of each process to determine which is better suited for your specific project. Thermoforming offers cost-effectiveness and design flexibility, but it comes with limitations in complexity and durability concerns. On the other hand, injection molding provides precision, consistency, and structural integrity, making it better than thermoforming for intricate and durable products.

Baoyuan's Specialization in Custom Plastic Solutions

At Baoyuan, we specialize in providing custom plastic solutions that meet the unique needs of our clients. With expertise in both thermoforming and injection molding techniques, we can offer tailored manufacturing methods to ensure the highest quality and functionality for your plastic products. Our commitment to excellence drives us to continuously improve our processes and deliver outstanding results.

Making Informed Decisions for Quality Plastic Production

When deciding between thermoplastic vs injection molding or injection molding vs vacuum forming, it's crucial to make informed decisions that align with your project goals. Consider factors such as material behavior, production efficiency, environmental impact, and sustainability to determine the most suitable manufacturing method. By partnering with Baoyuan, you can trust that you're making a well-informed choice for top-notch plastic production.

When deciding between thermoplastic vs injection molding or injection molding vs vacuum forming, it's crucial to make informed decisions that align with your project goals. Consider factors such as material behavior, production efficiency, environmental impact, and sustainability to determine the most suitable manufacturing method. By partnering with Baoyuan, you can trust that you're making a well-informed choice for top-notch plastic production.