Introduction

Injection molding is a manufacturing process that has become integral to producing a wide variety of plastic products. Understanding injection molding costs is crucial for businesses looking to optimize their production budgets and ensure profitability. With the ever-evolving landscape of manufacturing, knowing what influences these costs can make all the difference between a successful project and a financial misstep.

Understanding Injection Molding Costs

When delving into the cost of injection molding, it's essential to grasp not just the raw numbers but also what they entail. The cost of injection molding encompasses various elements, including materials, labor, and machinery investments, each playing a significant role in the overall expense. By breaking down these costs, manufacturers can better assess their budgetary needs and strategize effectively for future projects.

Importance of Accurate Cost Breakdown

Accurate cost breakdowns are vital for any business aiming to stay competitive in today's market. Without understanding how much does injection molding cost in its entirety—including hidden fees—companies risk overspending or underestimating their financial commitments. Furthermore, an accurate breakdown allows for informed decision-making regarding production methods and supplier selection.

Factors Influencing Injection Molding Expenses

Many factors influence injection molding expenses, making it crucial to analyze them thoroughly before diving into production. From material selection to labor rates and machine efficiency, each aspect can significantly affect overall costs. Additionally, understanding regional differences—such as how much does injection molding cost in China compared to Western countries—can provide insights that lead to more economical choices in manufacturing strategies.

Overview of Injection Molding

Injection molding is a manufacturing process that allows for the efficient production of complex shapes and designs. By injecting molten material into a mold, manufacturers can create parts with high precision and repeatability. This method is particularly favored in industries where consistency and quality are paramount.

What is Injection Molding?

At its core, injection molding involves melting plastic or other materials and injecting them into a pre-designed mold cavity. Once cooled, the material solidifies into the desired shape, making it an ideal choice for mass production. The process not only minimizes waste but also allows for intricate designs that would be difficult to achieve through traditional manufacturing methods.

Common Industries Utilizing Injection Molding

Numerous industries rely on injection molding to produce their components, including automotive, consumer goods, medical devices, and electronics. In the automotive sector, for instance, manufacturers create everything from dashboard components to intricate engine parts using this technique. Similarly, consumer goods companies use injection molding to produce everyday items like toys and kitchenware efficiently.

Benefits of Injection Molding

The benefits of injection molding extend beyond just efficiency; it also offers cost-effectiveness when considering large-scale production runs. While one might wonder about the cost of injection molding upfront—especially when asking What is the average cost of an injection mold?—the long-term savings often outweigh initial investments. Additionally, this method provides excellent design flexibility and can accommodate various materials, making it a versatile option for many projects.

Key Components of Injection Molding Cost

When diving into the cost of injection molding, it's essential to break down the primary components that contribute to overall expenses. Understanding these key elements helps businesses plan budgets and optimize production processes. In this section, we will explore material expenses, labor costs, and equipment investments that shape the financial landscape of injection molding.

Material Expenses in Injection Molding

Material expenses are a significant portion of the overall cost of injection molding. The choice of resin or plastic can dramatically affect pricing; for instance, high-performance materials like PEEK or polycarbonate come at a premium compared to standard polyethylene or polypropylene. Additionally, fluctuations in raw material prices due to market demand can lead to unpredictable costs—making it crucial for manufacturers to stay informed about current trends when calculating injection mold costs.

Moreover, recycling options and bulk purchasing can help mitigate some material expenses. By optimizing material usage through design improvements and reducing waste during production, companies can further manage their costs effectively. Ultimately, understanding how much does injection molding cost in terms of materials is vital for maintaining competitive pricing without sacrificing quality.

Labor Costs in the Injection Molding Process

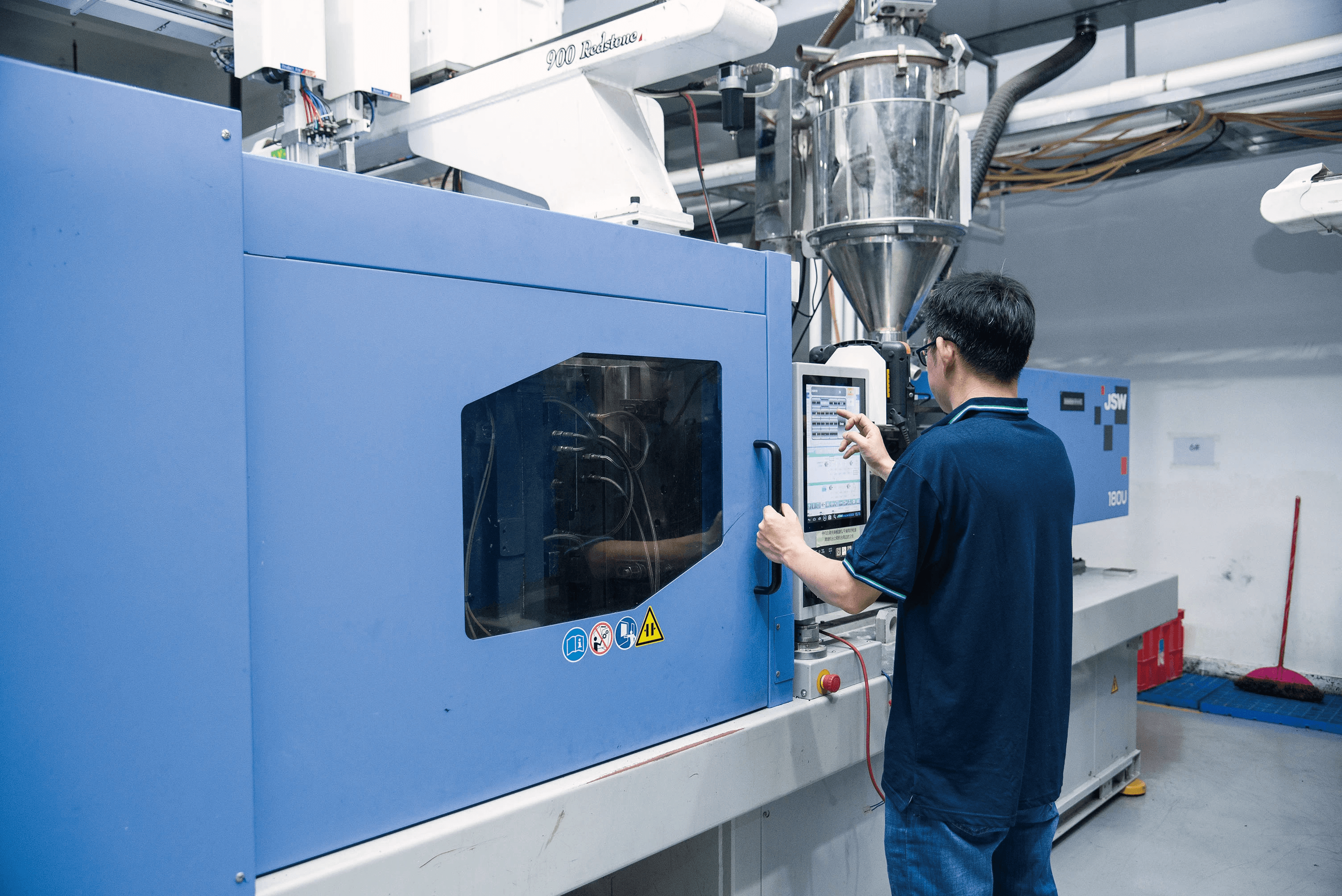

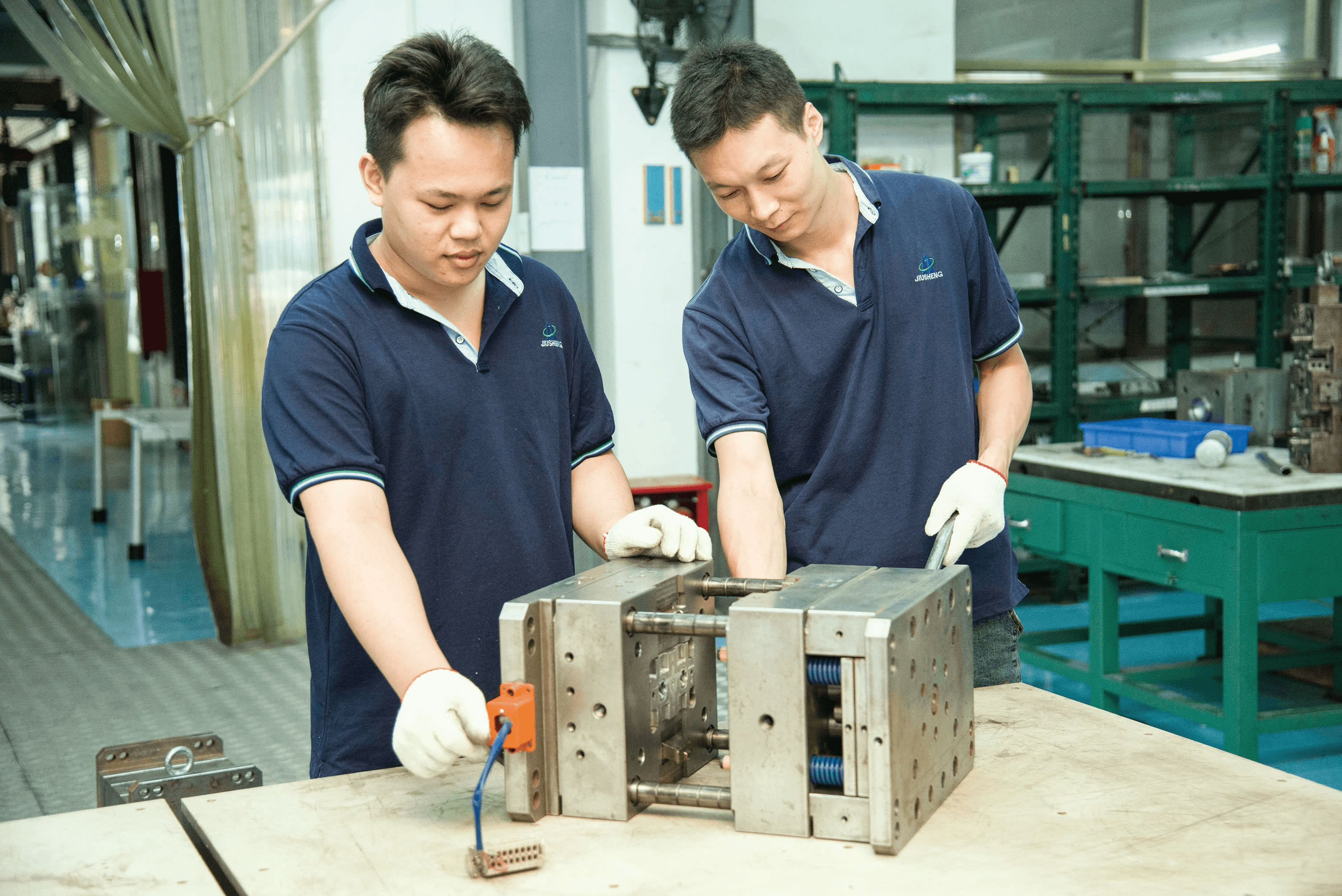

Labor costs represent another critical factor influencing the total cost of injection molding. Skilled technicians are required for operating machinery and ensuring that production runs smoothly; their expertise comes with a price tag that varies by region and industry standards. When evaluating how to calculate injection mold cost accurately, it's essential to factor in not just wages but also training and benefits associated with skilled labor.

Additionally, automation has started playing a more prominent role in reducing labor-related expenses within the industry. Automated systems can improve efficiency while minimizing human error—ultimately leading to lower operational costs over time. However, initial investments in technology may raise upfront expenditures; thus, weighing long-term savings against immediate labor costs is crucial when considering why does injection molding cost so much.

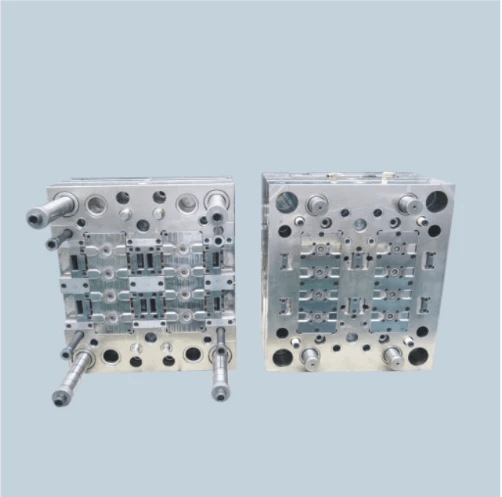

Equipment and Machinery Investments

Investing in high-quality equipment and machinery is paramount for successful injection molding operations but comes at a considerable expense—often one of the largest components impacting the average cost of an injection mold. Advanced machines equipped with cutting-edge technology not only enhance production speed but also improve precision and reduce waste during manufacturing processes. This investment pays off over time as improved efficiency translates into better profit margins.

However, it’s important to recognize that maintenance costs should also be included when assessing overall machinery investments; neglecting this aspect may lead to unexpected downtimes that further inflate production costs down the line. Moreover, companies need to stay abreast of technological advancements as outdated equipment could hinder competitiveness within an ever-evolving market landscape—especially when comparing how much does injection molding cost in China versus Western manufacturing environments where innovation may be prioritized differently.

In conclusion, understanding these key components—material expenses, labor costs, and equipment investments—is vital for any business involved in or considering entering the world of injection molding. By dissecting these factors clearly while keeping an eye on market trends and technological advancements will empower manufacturers with insights necessary for making informed decisions regarding their projects’ financial viability.

What is the Average Cost of an Injection Mold?

When it comes to understanding the cost of injection molding, one of the first questions that arise is, What is the average cost of an injection mold? The answer isn't straightforward as it varies widely based on several factors. However, a general understanding can help businesses budget more effectively and make informed decisions.

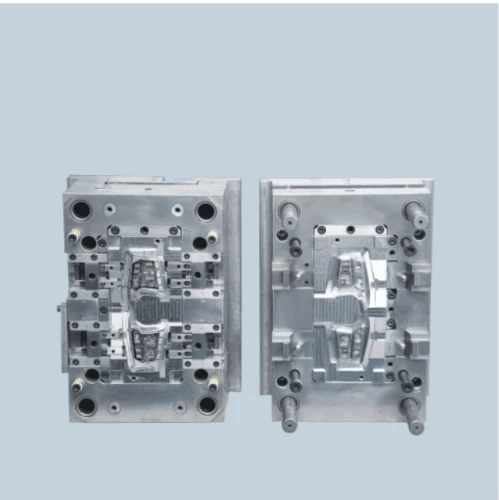

Factors Affecting Mold Pricing

Several key factors influence mold pricing in the injection molding industry. First and foremost, the complexity of the design plays a significant role; intricate designs require more detailed molds, which naturally drive up costs. Additionally, material selection for both the mold and the final product can impact pricing—high-performance materials come with higher price tags, impacting how much does injection molding cost overall.

Another crucial factor is production volume; molds designed for high-volume production typically have higher upfront costs but lower per-unit costs over time. The geographical location of manufacturing also affects prices; different regions have varying labor rates and overhead costs that contribute to overall expenses. Lastly, lead times and project timelines can influence costs; expedited services often come at a premium.

Typical Price Ranges in Injection Molding

So just how much does injection molding cost? Typically, basic molds can range from $1,000 to $5,000 for simple designs intended for low-volume production runs. On the other hand, more complex molds used for high-volume production can easily exceed $50,000 or even reach upwards of $100,000 depending on their intricacies and specifications.

For instance, industries such as automotive or medical devices often require highly specialized molds that fall into that higher price bracket due to stringent quality standards and advanced features needed. It's essential to remember that while initial investment may seem steep when considering What is the average cost of an injection mold?, these expenses are often offset by long-term savings through efficiency in mass production.

Comparison of Mold Costs Across Regions

When comparing mold costs across regions globally—especially when considering how much does injection molding cost in China—it becomes evident there are significant differences influenced by labor rates and material availability. In countries like China, where manufacturing processes are optimized for efficiency and labor rates are generally lower than in Western nations, companies might find substantial savings on both initial mold costs and ongoing production expenses.

However, this doesn't mean that quality should be compromised; many manufacturers in China adhere to high standards comparable with those found in Europe or North America. It’s crucial to evaluate not only price but also quality when assessing regional options because cheaper doesn’t always mean better value in terms of durability or precision—a common misconception about why does injection molding cost so much arises from this very notion.

How Much Does Injection Molding Cost in China?

When it comes to the cost of injection molding, China has become a go-to destination for many businesses looking to optimize their manufacturing expenses. The allure of lower labor costs, reduced overhead, and economies of scale makes it an attractive option for companies worldwide. However, understanding the nuances of how much injection molding costs in China requires a closer look at various factors that influence pricing.

Cost Advantages of Manufacturing in China

One of the most significant cost advantages of manufacturing in China is the remarkably low labor rates compared to Western countries. This reduction in labor costs can lead to substantial savings on overall production expenses, making it easier for businesses to maintain competitive pricing. Additionally, China's robust supply chain infrastructure and access to a wide range of materials contribute significantly to lowering the cost of injection molding.

Moreover, large-scale production capabilities allow Chinese manufacturers to achieve economies of scale that further decrease per-unit costs. This means that as your order volume increases, the average cost per item decreases due to more efficient use of resources and machinery. Therefore, if you’re asking yourself what is the average cost of an injection mold produced in China compared to other regions, you may find it significantly lower due to these advantages.

Quality vs. Cost in Chinese Injection Molding

While cost is a major factor when considering how much does injection molding cost in China, quality cannot be overlooked. Many businesses fear that lower prices equate with reduced quality; however, this isn't always true when working with reputable manufacturers who adhere to international standards. It’s essential for companies seeking quality assurance alongside affordability to conduct thorough research on potential partners.

In some cases, Chinese manufacturers have made considerable investments in technology and training that rival Western counterparts—resulting in high-quality products at competitive prices. Nevertheless, it's crucial for companies looking into how to calculate injection mold costs from Chinese sources also consider potential hidden costs associated with quality control measures or rework if standards are not met initially. Thus arises the need for diligence when assessing both price and quality.

Case Studies of China vs. Western Manufacturing

To illustrate the differences between manufacturing costs across regions effectively, let's consider a few case studies highlighting both sides' strengths and weaknesses regarding injection molding expenses. Company A opted for Chinese manufacturing due primarily to lower labor costs; they reported savings upwards of 40% compared with their previous U.S.-based supplier while maintaining product quality through rigorous testing procedures.

Conversely, Company B decided against outsourcing their injection molding needs despite higher upfront costs because they valued proximity and quicker turnaround times offered by local manufacturers—something often lost when dealing with overseas suppliers like those found in China. These real-world examples demonstrate why understanding why does injection molding cost so much involves more than just examining price tags; it encompasses evaluating all aspects related to time efficiency and product integrity as well.

How to Calculate Injection Mold Cost?

Calculating the cost of injection molding can seem daunting, but breaking it down into manageable parts makes the process much more straightforward. Understanding how to calculate injection mold cost helps manufacturers and businesses budget effectively for their projects. This section will guide you through the formula, essential variables, and insights from industry professionals.

Formula for Calculating Mold Costs

To determine the cost of an injection mold, you can use a basic formula that incorporates various factors like material costs, labor rates, and machine time. The general formula is: **Mold Cost = (Material Cost + Labor Cost + Machine Time) x Overhead Rate**. By using this formula, you can get a clearer picture of what is the average cost of an injection mold in your specific situation.

In practice, this means that if you're trying to figure out how much does injection molding cost in China versus other regions, you'll need to plug in local rates for each component of your calculation. Remember that while this formula provides a solid foundation, adjustments may be necessary based on unique project requirements or specific industry standards.

Essential Variables to Consider

When calculating injection mold costs, several essential variables come into play that can significantly affect your final price tag. First and foremost are material expenses; different plastics have varying costs per pound or kilogram which directly impacts your overall budget. Additionally, labor costs can fluctuate based on location and skill levels required for production.

Another critical variable is the complexity of the mold design itself—more intricate designs typically require more time and resources to produce, thus increasing costs. Furthermore, factors such as production volume also influence pricing; higher volumes often lead to lower per-unit costs due to economies of scale. Understanding these variables ensures you have a comprehensive view when exploring why does injection molding cost so much.

Insights from the Baoyuan Team on Cost Calculations

The Baoyuan team emphasizes that accurate calculations hinge on thorough planning and clear communication with all stakeholders involved in the project. They recommend conducting market research to understand regional differences—especially when considering how much does injection molding cost in China compared to Western manufacturing options. By gathering data from multiple sources and consulting with experts who specialize in mold creation, you’ll be better equipped to estimate realistic budgets.

Moreover, they suggest utilizing software tools designed specifically for estimating manufacturing costs; these tools can help streamline calculations while ensuring all relevant factors are accounted for efficiently. Ultimately, investing time into understanding how to calculate injection mold cost not only aids in budgeting but also sets up projects for success by avoiding unexpected financial pitfalls down the line.

Why Does Injection Molding Cost So Much?

When diving into the world of injection molding, one question looms large: why does injection molding cost so much? The costs associated with this manufacturing process can be daunting for newcomers and seasoned professionals alike. Understanding the breakdown of these expenses is crucial to making informed decisions about your production needs.

Breakdown of High Costs in Injection Molding

The cost of injection molding is influenced by several key factors, starting with the materials used. High-quality thermoplastics and additives can significantly impact material expenses, which often account for a substantial portion of the overall budget. Additionally, labor costs play a vital role; skilled technicians are required to operate machinery and ensure quality control, further driving up expenses.

Another significant contributor to high costs is the initial investment in equipment and tooling. The average cost of an injection mold can range widely based on complexity and size, often requiring thousands to tens of thousands of dollars upfront. Moreover, ongoing maintenance and operational costs for machinery add another layer that manufacturers must navigate when considering their budget.

Lastly, design intricacies cannot be overlooked—complex parts require more sophisticated molds that elevate production costs. This leads many businesses to ponder not just what is the average cost of an injection mold but also how those costs will affect their bottom line over time.

Long-term Benefits vs. Initial Investment

While the initial outlay for injection molding might seem exorbitant at first glance, it’s essential to weigh these expenditures against long-term benefits. For instance, once a mold is created, it can produce thousands or even millions of parts with minimal additional cost per unit—a significant advantage for high-volume production runs. This scalability makes injection molding particularly attractive for businesses looking to ramp up production without incurring proportional increases in manufacturing expenses.

Moreover, investing in quality molds ensures durability and precision in each part produced, leading to fewer defects and lower rework rates down the line—ultimately saving money in post-production processes. Thus, while many may wonder how much does injection molding cost initially, they should also consider potential savings from enhanced efficiency over time.

In regions like China where manufacturing costs are lower—how much does injection molding cost in China?—the long-term benefits remain consistent despite varying initial investments across different geographical locations.

Addressing Common Misconceptions

There are numerous misconceptions surrounding why does injection molding cost so much that deserve clarification. One common belief is that cheaper materials always lead to reduced overall expenses; however, using subpar materials can result in higher rejection rates due to defects or failures during use—leading to increased waste and re-manufacturing costs later on.

Another misconception revolves around mold reuse; while it's true that molds can be reused multiple times, they do wear down over time requiring repairs or replacements which add unforeseen expenses back into your budget equation. Therefore understanding how to calculate injection mold cost accurately includes factoring potential future repairs as part of your financial planning process.

In conclusion, recognizing these nuances helps demystify the pricing structure behind injection molding services and empowers businesses with knowledge about what influences their overall expenditures—from material selection all the way through operational practices.

Conclusion

In wrapping up our exploration of injection molding costs, it's clear that understanding the financial landscape is crucial for any business considering this manufacturing method. The cost of injection molding can vary significantly based on factors such as materials, labor, and equipment investments. By breaking down these components, manufacturers can make informed decisions that align with their budget and project goals.

Summarizing Injection Molding Costs

The cost of injection molding encompasses a variety of elements, including the average cost of an injection mold itself and ongoing production expenses. Typically, businesses must consider not just the initial mold price but also recurring costs like material and labor to get a full picture. This multifaceted approach helps ensure that companies are not caught off guard by hidden expenses down the line.

Finding the Best Value for Your Project

When seeking the best value for your project, it’s essential to weigh both quality and cost in your decision-making process. Understanding how much does injection molding cost in China can provide significant insights into potential savings while maintaining acceptable quality levels. Moreover, knowing how to calculate injection mold cost accurately allows businesses to evaluate various suppliers effectively and negotiate better deals.

Future Trends in Injection Molding Pricing

Looking ahead, we can anticipate several trends influencing the future pricing landscape of injection molding. As technology advances and automation becomes more prevalent, we may see a shift in why does injection molding cost so much today; efficiency could lead to lower costs overall. Additionally, environmental considerations will likely play a role in shaping pricing structures as sustainable practices gain traction in manufacturing processes.