Introduction

Are you looking for cost-effective solutions in low-scale plastic moulding? Look no further! In this guide, we will explore the Baoyuan approach to plastic moulding and how it can benefit your business. Whether you're wondering about the cheapest type of plastic molding or how thin plastic can be molded, we've got you covered with expert insights and practical advice.

Understanding Low-Scale Plastic Injection Moulding

Low-scale plastic injection moulding is a versatile process that allows for the production of small to medium-sized plastic parts with precision and efficiency. It's a cost-effective solution for businesses looking to create custom components without breaking the bank. With Baoyuan's expertise in this area, you can trust that your moulding needs will be met with excellence and reliability.

Exploring Cost-Effective Solutions

When it comes to cost-effective solutions in plastic moulding, low volume injection molding is a game-changer. This method allows for small batches of parts to be produced at a fraction of the cost of traditional mass production techniques. Baoyuan specializes in small scale plastic manufacturing, offering competitive pricing without sacrificing quality or performance.

The Baoyuan Approach to Plastic Moulding

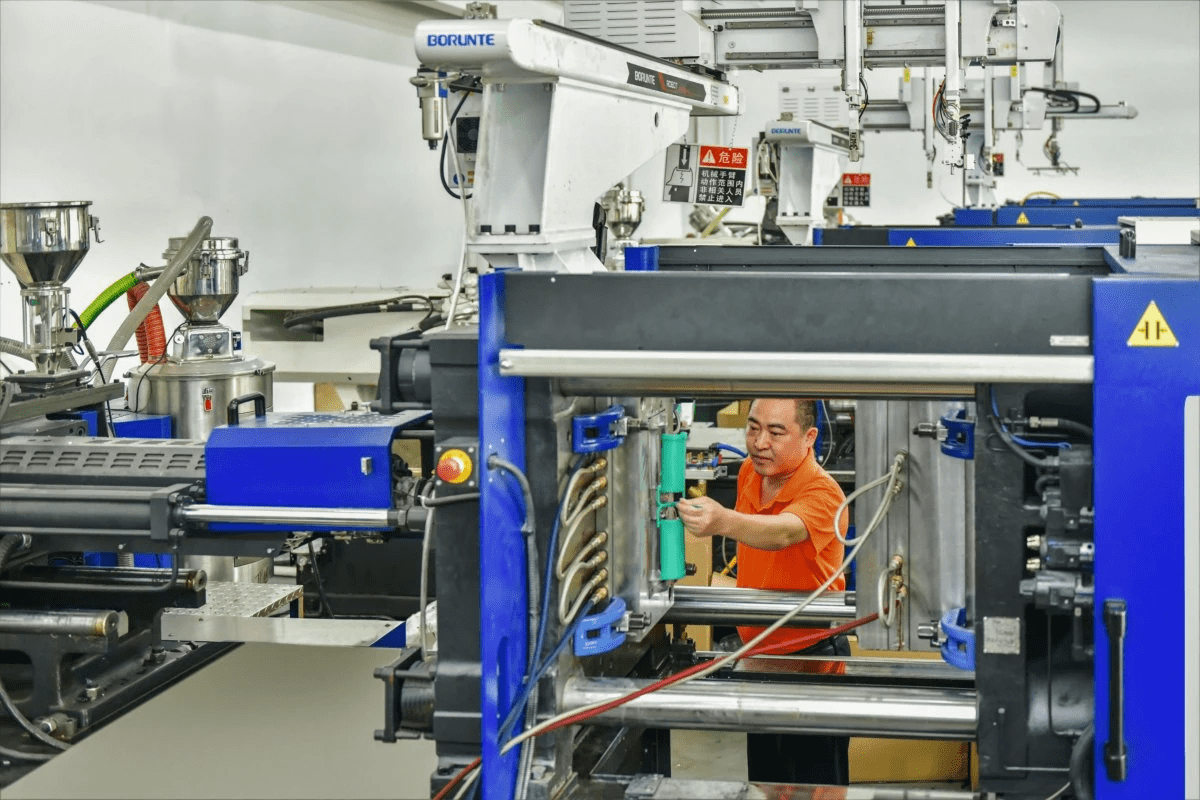

Baoyuan's approach to plastic moulding is centered around maximizing efficiency and minimizing waste. With state-of-the-art technology and innovative techniques, they are able to produce high-quality parts while keeping costs down. Their commitment to sustainable practices sets them apart as leaders in the industry, making them the ideal partner for all your low-scale plastic moulding needs.

The Basics of Low-Scale Plastic Moulding

Choosing the Right Materials

When it comes to low-scale plastic moulding, selecting the appropriate materials is crucial for achieving the desired product quality and cost-effectiveness. Baoyuan offers a wide range of materials, including thermoplastics and thermosetting plastics, to meet various manufacturing needs.

Selecting the right material is the foundation of successful low-scale plastic moulding. Baoyuan's wide range of materials, including thermoplastics and thermosetting plastics, ensures that manufacturers can find the perfect fit for their specific needs. Whether it's durability, flexibility, or heat resistance, Baoyuan has the materials to deliver high-quality products while keeping costs in check.

Understanding Moulding Techniques

Understanding different moulding techniques is essential for low-scale plastic moulding. Baoyuan specializes in injection moulding, blow moulding, and compression moulding, ensuring that each technique is utilized effectively to produce high-quality plastic products at a low cost.

Baoyuan's expertise in plastic moulding extends beyond just the technical aspects of the process. With a deep understanding of material properties and production efficiency, Baoyuan is able to optimize each moulding technique for maximum output and minimal waste. This comprehensive approach allows for the creation of durable, high-quality plastic products that meet the needs of diverse industries, from automotive to consumer goods.

Baoyuan's Expertise in Plastic Moulding

Baoyuan has extensive expertise in low-scale plastic moulding, providing innovative solutions for small scale plastic manufacturing. Their team of professionals is well-versed in the cheapest type of plastic molding, utilizing their knowledge to deliver cost-effective and efficient results.

Baoyuan's extensive expertise in low-scale plastic moulding allows them to offer innovative solutions for small scale plastic manufacturing. Their team of professionals is well-versed in the cheapest type of plastic molding, enabling them to deliver cost-effective and efficient results. With a focus on quality and precision, Baoyuan ensures that their moulding solutions meet the highest standards and specifications, providing clients with durable and reliable products.

Cost-Effective Moulding Solutions

Utilizing Low Volume Injection Molding

When it comes to low-scale plastic moulding, utilizing low volume injection molding can be a game-changer. This cost-effective method allows for the production of small quantities of plastic parts without sacrificing quality. Baoyuan's expertise in low volume injection molding ensures efficient and affordable solutions for your specific needs.

Furthermore, low volume injection molding allows for greater design flexibility, making it ideal for prototyping and small-scale production runs. Baoyuan's team of experienced engineers can work closely with you to optimize the design of your plastic parts, ensuring that they meet your specific requirements and quality standards. This collaborative approach ensures that you get the exact results you need, without compromising on quality or functionality.

Baoyuan's Small Scale Plastic Manufacturing Advantages

Baoyuan's small scale plastic manufacturing advantages lie in our ability to offer customized solutions at competitive prices. Our state-of-the-art equipment and skilled workforce enable us to produce high-quality plastic products in smaller quantities without compromising on quality or efficiency.

What is the Cheapest Type of Plastic Molding?

When considering cost-effective moulding solutions, it's essential to understand that low volume injection molding is often the cheapest type of plastic molding for small-scale production runs. This method allows for the production of precise and high-quality parts at a lower cost, making it an ideal choice for businesses looking to minimize expenses while maintaining product integrity.

Remember, when it comes to cost-effective moulding solutions, Baoyuan is your trusted partner in delivering high-quality products at competitive prices while utilizing innovative techniques such as low volume injection molding and small scale plastic manufacturing advantages.

Maximizing Efficiency in Plastic Moulding

How Thin Can Plastic Be Molded?

When it comes to low-scale plastic moulding, the thickness of the plastic can vary depending on the material and the moulding technique used. Baoyuan specializes in precision moulding, allowing for thin plastic parts to be produced with high accuracy and consistency. This expertise enables cost-effective production of intricate plastic components for various industries.

Baoyuan's innovative moulding technology allows for the production of ultra-thin plastic parts with exceptional precision. This advanced technology enables the manufacturing of intricate and delicate components that were previously thought to be impossible to produce. With Baoyuan's expertise in precision moulding, clients can expect consistent quality and cost-effective production of thin plastic parts for a wide range of applications.

Baoyuan's Innovative Moulding Technology

Baoyuan utilizes state-of-the-art moulding technology that maximizes efficiency and minimizes waste in the production process. Their innovative approach ensures that each moulded part meets strict quality standards while keeping costs low for small-scale manufacturing projects. This commitment to innovation sets them apart as leaders in the field of plastic moulding.

Baoyuan's commitment to innovation in moulding technology is evident in their continuous investment in research and development. By staying at the forefront of technological advancements, they are able to offer their clients the most cutting-edge solutions for their plastic moulding needs. This dedication to staying ahead of the curve not only benefits Baoyuan, but also ensures that their customers receive the highest quality products available on the market.

Baoyuan's Quality Assurance in Plastic Products

In low-scale plastic manufacturing, quality assurance is crucial to ensure that each part meets specifications and performs as intended. Baoyuan's rigorous quality control processes guarantee that every plastic product is free from defects and consistently meets customer requirements, providing peace of mind for clients seeking reliable and cost-effective solutions.

Types of Plastic Moulding

Exploring Different Types of Plastic Moulding

When it comes to low-scale plastic moulding, there are various techniques to consider. From injection moulding to blow moulding, each method has its own advantages and applications. Understanding the different types of plastic moulding can help you choose the best option for your specific needs.

The Cheapest Way to Make Plastic Parts

For cost-effective plastic moulding, low volume injection molding is often considered the cheapest option. This method allows for small batch production without sacrificing quality or precision. With Baoyuan's expertise in low volume injection molding, you can achieve high-quality plastic parts at a competitive price.

Baoyuan's Proficiency in Single-Color and Double-Color Plastic Products

Baoyuan is proficient in producing both single-color and double-color plastic products with precision and efficiency. Whether you need simple single-color parts or more complex double-color components, Baoyuan's advanced moulding technology can meet your requirements while maintaining cost-effectiveness.

Sustainable Practices in Plastic Moulding

Eco-Friendly Approaches to Moulding

When it comes to low-scale plastic moulding, eco-friendly practices are essential. Baoyuan is dedicated to using sustainable materials and reducing waste in their manufacturing process. By implementing energy-efficient machinery and recycling plastic waste, they minimize their environmental impact while still delivering high-quality products.

In addition to using sustainable materials and energy-efficient machinery, Baoyuan also focuses on reducing their carbon footprint by optimizing their production processes. By streamlining their operations and minimizing the use of resources, they are able to further decrease waste and energy consumption. This commitment to sustainable manufacturing not only benefits the environment but also demonstrates Baoyuan's dedication to responsible business practices.

Baoyuan's Commitment to Sustainable Manufacturing

Baoyuan's commitment to sustainable manufacturing extends beyond just the production process. They actively seek out innovative ways to reduce their carbon footprint and invest in eco-friendly initiatives within their community. By prioritizing sustainability, they set a new standard for low-scale plastic moulding that benefits both the industry and the environment.

Baoyuan's Skilled Use of Software for Mold Design and Injection Molding

Baoyuan leverages advanced software for mold design and injection molding, allowing them to optimize material usage and minimize waste during the production of plastic parts. This innovative approach not only enhances efficiency but also contributes to their eco-friendly practices, making them a leader in sustainable low-scale plastic moulding solutions.

Moreover, Baoyuan's use of advanced software for mold design and injection molding also allows for greater precision and accuracy in the production process. This results in higher quality plastic parts that meet strict industry standards, further solidifying their reputation as a top-tier manufacturer. By prioritizing both efficiency and quality, Baoyuan sets itself apart from competitors in the low-scale plastic moulding market.

Conclusion

When it comes to your moulding needs, it's crucial to choose a cost-effective solution that doesn't compromise on quality. Baoyuan's expertise in low-scale plastic moulding ensures that you get the best bang for your buck without sacrificing durability and precision. With their commitment to sustainable practices and innovative technology, Baoyuan is the partner you can rely on for all your small scale plastic manufacturing requirements.

Choosing the Right Solution for Your Moulding Needs

Understanding the different types of plastic moulding and the cheapest way to make plastic parts is essential in making an informed decision for your specific needs. Low volume injection molding is a cost-effective solution for small-scale production, while Baoyuan's proficiency in this area ensures top-notch results every time. When it comes to choosing the right solution for your moulding needs, it's important to consider factors such as material selection, design complexity, and production volume. Baoyuan's expertise in low volume injection molding allows for flexibility in meeting these criteria, ensuring that your specific requirements are met with precision and efficiency.

Baoyuan: Your Partner for Cost-Effective Moulding Solutions

Baoyuan's dedication to maximizing efficiency in plastic moulding means that they can mold plastics thinner than most, using their innovative technology and quality assurance processes. Their expertise in single-color and double-color plastic products makes them the go-to partner for all your cost-effective moulding solutions.

Baoyuan's commitment to staying ahead of the curve in plastic moulding technology means that they are constantly innovating and improving their processes. This dedication allows them to offer cost-effective solutions for low-scale plastic injection moulding, providing their clients with high-quality products at competitive prices. By leveraging their expertise in single-color and double-color plastic products, Baoyuan is able to meet the diverse needs of their customers, making them a reliable partner for all moulding requirements.

The Future of Low-Scale Plastic Injection Moulding

As the industry continues to evolve, Baoyuan remains at the forefront with their sustainable practices and skilled use of software for mold design and injection molding. The future of low-scale plastic injection moulding is bright with Baoyuan leading the way in providing high-quality, affordable solutions. With a focus on innovation, Baoyuan is constantly exploring new materials and technologies to improve the efficiency and environmental impact of their processes. Additionally, their commitment to research and development ensures that they stay ahead of industry trends and continue to offer cutting-edge solutions to their clients.