Introduction

When it comes to custom injection molding, cost is a crucial consideration. Whether you're wondering How much does it cost to make an injection mold? or How much does injection molding cost per part? Baoyuan has the expertise in providing cost-effective solutions. Understanding the key factors in custom injection molding cost is essential for making informed decisions.

Understanding Custom Injection Molding Costs

Custom injection molding costs can vary based on factors such as material, design complexity, and production volume. It's important to calculate injection molding cost accurately to avoid unexpected expenses. Baoyuan specializes in offering transparent and competitive pricing for custom injection molding projects.

Baoyuan's Expertise in Cost-effective Solutions

Baoyuan has a proven track record of delivering high-quality yet affordable custom injection molding solutions. By optimizing production processes and leveraging efficient design techniques, Baoyuan ensures that clients receive the best value for their investment.

Key Factors in Custom Injection Molding Cost

Factors such as tooling costs, material selection, and part complexity can significantly impact custom injection molding cost. Baoyuan's team of experts understands how to navigate these variables to provide clients with the most cost-effective options without compromising on quality.

Calculating Custom Injection Molding Cost

When it comes to understanding custom injection molding cost, Baoyuan has developed a comprehensive method for calculating injection molding cost that takes into account all the necessary factors. By considering variables such as material costs, tooling expenses, and production time, Baoyuan ensures an accurate assessment of the total cost for each project.

Baoyuan's Method for Calculating Injection Molding Cost

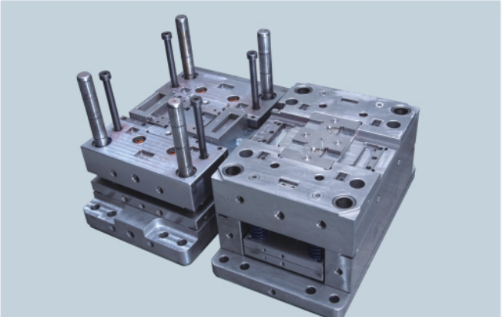

Baoyuan's method involves a detailed breakdown of all the components involved in the injection molding process. This includes evaluating the complexity of the part design, determining the type and quantity of materials required, and assessing the intricacy of the mold. By meticulously analyzing these elements, Baoyuan is able to provide clients with an accurate estimate of their custom injection molding cost.

Furthermore, Baoyuan's method takes into account the production volume and cycle time required for each part, as these factors can significantly impact the overall cost. By considering the number of units to be produced and the time it takes to manufacture each part, Baoyuan is able to provide a more comprehensive and accurate cost estimate for clients. This level of detail allows clients to make informed decisions about their injection molding projects and budget accordingly.

Factors Affecting Injection Molding Cost

Factors that can affect injection molding cost include part complexity, material selection, tooling requirements, and production volume. Baoyuan takes all these variables into consideration when calculating custom injection molding cost to ensure clients have a clear understanding of how each factor impacts overall pricing.

Common Misconceptions About Injection Molding Cost

One common misconception about injection molding cost is that it is solely determined by part volume. In reality, factors such as part design complexity and material selection can have a significant impact on overall cost. Baoyuan aims to debunk these misconceptions by providing transparent and detailed explanations of how various elements contribute to custom injection molding cost.

It's important to understand that part design complexity plays a crucial role in determining injection molding cost. Intricate designs with undercuts, threads, or complex geometries may require more complex tooling and longer production times, ultimately driving up the overall cost. Additionally, material selection can significantly impact cost as well. High-performance engineering resins or specialty materials may come with a higher price tag compared to standard commodity plastics, adding to the overall production cost. These factors need to be carefully considered and optimized for a cost-effective injection molding process.

Efficient Design for Cost-effective Injection Molding

When it comes to efficient mold design, Baoyuan's approach focuses on maximizing functionality while minimizing material and production costs. By leveraging cutting-edge design software and extensive industry experience, Baoyuan is able to create molds that are not only cost-effective but also highly efficient in producing high-quality parts.

Baoyuan's Approach to Efficient Mold Design

Baoyuan's approach to mold design involves meticulous attention to detail, ensuring that every aspect of the mold is optimized for cost-effectiveness. From the selection of materials to the intricacies of part geometry, Baoyuan's expert designers prioritize efficiency without compromising on quality. This results in molds that deliver exceptional performance at a fraction of the cost.

Baoyuan's meticulous approach to mold design also involves a keen understanding of the production process, allowing for the identification of potential bottlenecks and areas for improvement. By addressing these issues early in the design phase, Baoyuan's team can streamline the manufacturing process, reducing lead times and minimizing overall production costs. This proactive approach not only saves time and money but also ensures that the final product meets or exceeds quality standards.

Design Considerations for Minimizing Injection Molding Cost

In order to minimize injection molding cost, there are several key design considerations that must be taken into account. These include part complexity, wall thickness, draft angles, and undercuts. By carefully evaluating these factors during the design phase, manufacturers can significantly reduce material usage and production time, ultimately driving down overall costs.

Another important design consideration for minimizing injection molding cost is the choice of material. Selecting the right material for the specific application can have a significant impact on cost, as some materials are more expensive than others. By carefully evaluating the performance requirements of the part and choosing a material that meets those requirements at the lowest cost, manufacturers can effectively reduce overall production expenses.

Balancing Cost and Quality in Mold Design

Balancing cost and quality in mold design is a delicate art that Baoyuan has mastered through years of experience. By strategically optimizing designs for manufacturability and performance, Baoyuan ensures that every mold strikes the perfect balance between cost-effectiveness and exceptional quality. This approach not only reduces upfront expenses but also minimizes long-term maintenance and replacement costs.

By leveraging advanced technology and innovative materials, Baoyuan is able to create molds that are not only cost-effective but also highly durable and efficient. This means that clients can benefit from reduced production downtime and increased output, ultimately leading to greater profitability. Additionally, the use of high-quality materials ensures that the molds have a longer lifespan, further contributing to cost savings in the long run.

Optimizing Production for Cost-effective Injection Molding

In order to optimize production for cost-effective injection molding, Baoyuan employs several key strategies. By utilizing advanced technology and automation, they are able to increase production efficiency and reduce labor costs. Additionally, Baoyuan focuses on minimizing material waste through precise control and monitoring of the injection molding process, ultimately lowering overall production costs.

Baoyuan's Strategies for Optimizing Injection Molding Production

Baoyuan's strategies for optimizing injection molding production include implementing cutting-edge machinery and robotics to streamline the manufacturing process. By automating repetitive tasks, they are able to significantly reduce labor costs while increasing output efficiency. This approach not only saves time but also minimizes the risk of human error, resulting in higher quality products at a lower cost.

In addition to implementing cutting-edge machinery and robotics, Baoyuan also focuses on optimizing the design of molds and tooling to further reduce injection molding costs. By utilizing advanced computer-aided design (CAD) software and simulation tools, they are able to create more efficient molds that require less material and energy to produce. This not only lowers production costs but also contributes to a more sustainable manufacturing process, aligning with Baoyuan's commitment to environmental responsibility.

Streamlining Processes to Reduce Injection Molding Cost

To reduce injection molding cost, Baoyuan places a strong emphasis on streamlining processes throughout the entire production cycle. This includes optimizing mold design and tooling to minimize cycle times and maximize productivity. By identifying and eliminating inefficiencies in the manufacturing process, they are able to achieve significant cost savings without sacrificing product quality.

Quality Assurance Techniques for Cost-effective Production

In addition to optimizing production processes, Baoyuan implements rigorous quality assurance techniques to ensure cost-effective production without compromising on quality. Through advanced inspection methods and stringent quality control measures, they are able to identify potential issues early on in the manufacturing process, reducing the risk of costly errors and rework. This proactive approach not only saves time and money but also ensures that each part meets the highest standards of quality.

Furthermore, Baoyuan invests in state-of-the-art technology and equipment to support their quality assurance efforts. By utilizing cutting-edge machinery and software, they are able to conduct thorough inspections and analysis, ensuring that every product meets the required specifications. This commitment to technological innovation not only enhances the accuracy of their quality control processes but also allows for greater efficiency in identifying and addressing any potential issues.

Baoyuan's Case Studies in Cost-effective Injection Molding

At Baoyuan, we pride ourselves on providing successful cost-effective solutions for custom injection molding projects. By leveraging our expertise in efficient design and production optimization, we have consistently delivered high-quality parts at competitive prices for our clients. Our commitment to cost efficiency has earned us a reputation as a trusted partner in the industry.

Successful Cost-effective Solutions by Baoyuan

One of our notable success stories involves a client who needed a large volume of precision parts within a tight budget. Through careful analysis and innovative mold design, we were able to significantly reduce the per-part cost without compromising quality. This not only met the client's financial expectations but also exceeded their performance requirements, showcasing our ability to deliver value-driven solutions.

After proving our ability to deliver cost-effective solutions without sacrificing quality, we continued to work with the client to optimize the production process. By implementing lean manufacturing principles and streamlining the supply chain, we were able to further reduce lead times and minimize waste, resulting in additional cost savings for the client. This collaborative approach not only strengthened our partnership with the client but also demonstrated our commitment to continuous improvement and long-term value creation.

Real-world Examples of Cost-effective Injection Molding

In another instance, we worked with a startup company looking to bring their product to market without breaking the bank. By optimizing production processes and utilizing advanced materials, we were able to minimize injection molding costs per part while maintaining excellent surface finish and dimensional accuracy. This allowed the client to launch their product successfully while staying within their budget constraints.

In addition, we collaborated with a well-established company in the automotive industry to help them reduce injection molding costs for a new line of interior components. By re-evaluating the design and material selection, we were able to streamline the production process and achieve significant cost savings without sacrificing quality. This allowed our client to remain competitive in the market and allocate resources to other areas of their business.

Baoyuan's Innovative Approaches to Minimizing Injection Molding Cost

Our team continuously explores innovative approaches to minimizing injection molding costs, such as implementing lightweighting techniques and material substitution strategies without sacrificing structural integrity or performance. These forward-thinking methods enable us to offer competitive pricing while ensuring that our clients receive top-notch products that meet their specifications.

By showcasing real-world case studies and success stories, Baoyuan demonstrates its proficiency in delivering cost-effective solutions for custom injection molding projects. Our innovative approaches and commitment to excellence make us the go-to partner for businesses seeking high-quality parts at competitive prices.

Conclusion

When it comes to achieving cost-effective custom injection molding, Baoyuan's expertise in minimizing custom injection molding costs is unmatched. With a proven track record in injection molding cost efficiency, Baoyuan has consistently delivered innovative and cost-effective solutions for their clients. Embracing cost-effective solutions for injection molding is essential for businesses looking to minimize custom injection molding costs and maximize their bottom line.

Achieving Cost-effective Custom Injection Molding

Understanding how much does it cost to make an injection mold is crucial in achieving cost-effective custom injection molding. By partnering with Baoyuan, businesses can benefit from their method for calculating injection molding cost and gain insights into factors affecting injection molding cost. This knowledge empowers businesses to make informed decisions that result in efficient design and production processes, ultimately leading to significant savings on custom injection molding costs.

Baoyuan's Proven Track Record in Injection Molding Cost Efficiency

Baoyuan's proven track record in injection molding cost efficiency is evident through their successful case studies in delivering cost-effective solutions for their clients. Real-world examples of cost-effective injection molding demonstrate Baoyuan's innovative approaches to minimizing custom injection molding costs while maintaining high-quality standards. By leveraging Baoyuan's expertise, businesses can achieve significant savings on custom injection molding costs without compromising on quality.

Embracing Cost-effective Solutions for Injection Molding

Embracing cost-effective solutions for injection molding is the key to optimizing production and achieving substantial savings on custom injection molding costs. Through efficient mold design, streamlined production processes, and quality assurance techniques, businesses can minimize the overall injection moulding cost per part and per hour. By embracing these strategies, companies can effectively reduce plastic injection moulding costs and enhance their competitive edge in the market.