Introduction

Are you curious about the world of plastic injection molding? This fascinating process involves creating intricate and durable plastic products through the use of an injection mold. Understanding the basics of plastic injection molding is crucial for anyone interested in this industry. From the cost considerations to quality solutions, it's a complex yet rewarding field to explore.

The Basics of Plastic Injection Molding

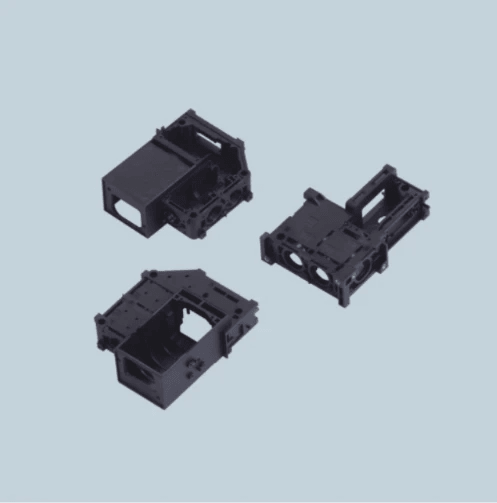

Plastic injection molding is a manufacturing process that involves injecting molten material into a mold, which then cools and solidifies into the desired shape. This versatile method is used to create a wide range of products, from small components to large automotive parts.

Understanding Injection Molding Costs

One common question in the industry is, How much does injection molding cost per hour? The answer depends on various factors such as the complexity of the mold, material used, and machine efficiency. It's essential for businesses to carefully consider custom injection molding costs to ensure profitability.

Quality Plastic Injection Molding Solutions

When it comes to plastic injection molding services, quality is paramount. From designing molds to delivering high-quality products, finding a reliable partner is crucial for businesses in this industry. Whether it's single-color or double-color plastic products, quality assurance should never be compromised.

The Baoyuan Advantage

At Baoyuan, our team is comprised of seasoned professionals with extensive experience in injection molding. Our senior management and technical personnel bring a wealth of knowledge and expertise to the table, ensuring that every project is handled with precision and care. With their guidance, we are able to consistently deliver high-quality plastic products that meet our clients' exact specifications.

Expertise of Baoyuan's Senior Management and Technical Personnel

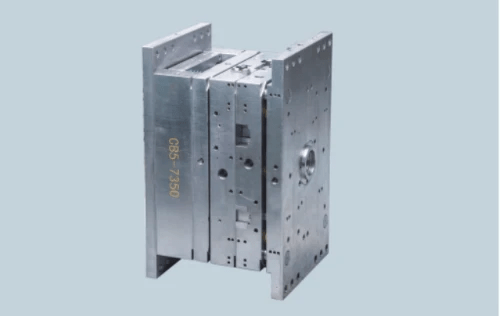

Our senior management and technical personnel have a deep understanding of the intricacies involved in injection molding. They possess the skills and knowledge necessary to oversee the entire process, from mold design to final product inspection. Their expertise allows us to tackle even the most complex projects with confidence, ensuring that our clients receive top-notch results every time.

In addition to their expertise in injection molding, our senior management and technical personnel are also proficient in designing molds that meet the specific requirements of each project. Their keen eye for detail and innovative approach ensure that the molds are not only functional but also efficient, resulting in cost-effective production processes. This level of proficiency allows us to deliver high-quality products to our clients within the agreed-upon timelines.

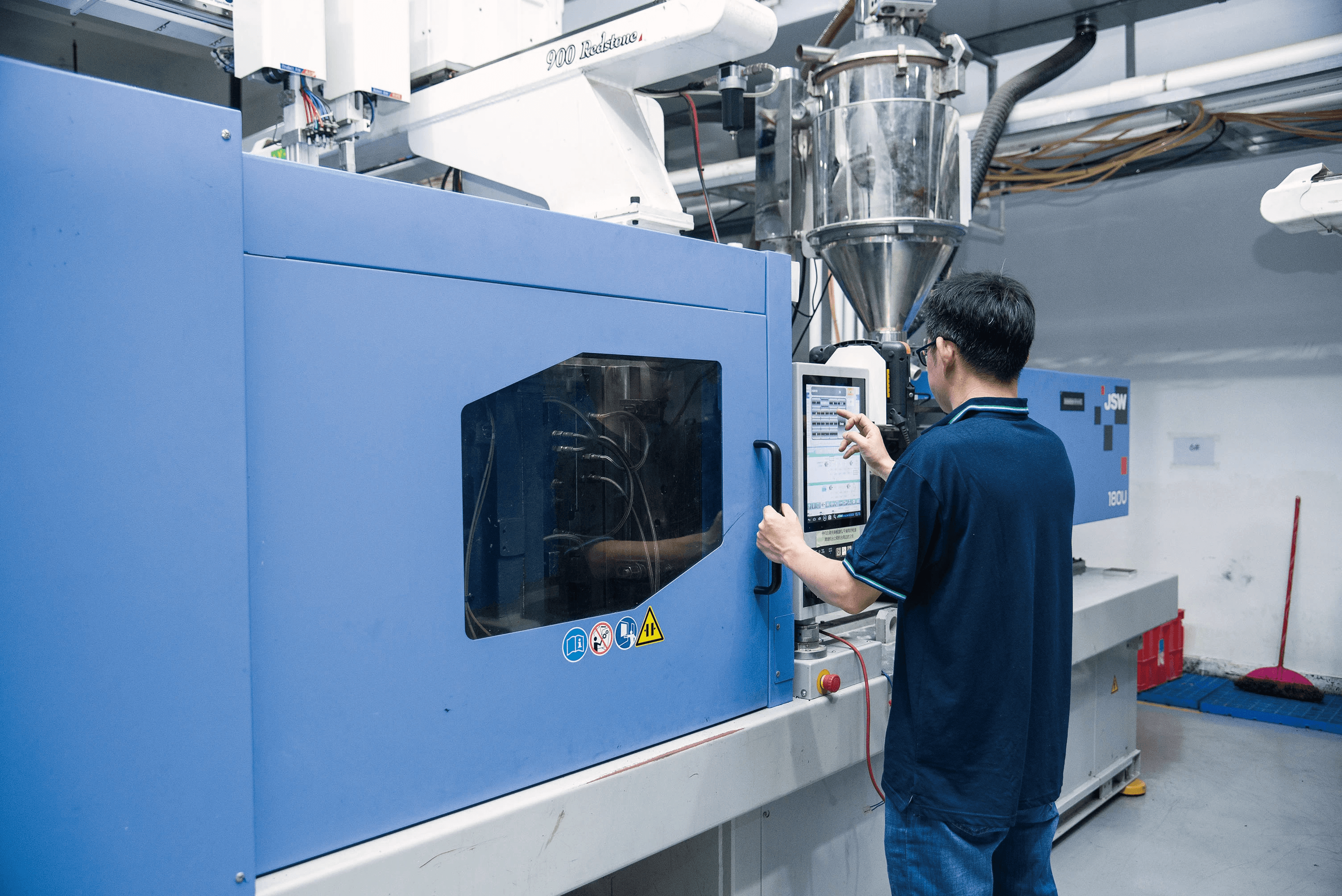

Proficiency in Designing Molds and Injection Molding

Baoyuan takes pride in our proficiency in designing molds and executing injection molding processes. We leverage cutting-edge technology and innovative techniques to create molds that are tailored to each client's unique needs. Our skilled technicians operate state-of-the-art injection molding machines, guaranteeing precise and efficient production runs for all types of plastic products.

Furthermore, our quality assurance team meticulously inspects every single-color and double-color plastic product to ensure that they meet the highest standards. We take pride in delivering flawless products to our clients, and our rigorous quality control process guarantees that each item is free from defects and imperfections. With Baoyuan, you can trust that your plastic products will not only be expertly designed and manufactured but also of the utmost quality.

Quality Assurance for Single-Color and Double-Color Plastic Products

We understand the importance of quality assurance when it comes to single-color and double-color plastic products. At Baoyuan, we have implemented stringent quality control measures at every stage of the injection molding process. This ensures that each product meets our high standards for durability, consistency, and aesthetic appeal, giving our clients peace of mind knowing they are receiving top-tier results.

Cost-Effective Solutions

When considering custom injection molding costs, it's essential to factor in the design, material, and production expenses. The complexity of the injection mold, the type of plastic used, and the quantity of parts required all play a significant role in determining the final cost.

Custom Injection Molding Cost Considerations

Custom injection molding costs are influenced by various factors such as tooling costs, material selection, part complexity, and production volume. It's crucial to work closely with a reputable injection molding company like Baoyuan to accurately assess these costs and ensure that your project stays within budget.

In addition to the factors mentioned, it's important to consider the impact of design changes on custom injection molding costs. Even small alterations to the part design can affect tooling and material requirements, ultimately impacting the overall cost. Therefore, it's essential to carefully evaluate and finalize the design before moving forward with the injection molding process. Working closely with an experienced injection molding company can help identify potential cost-saving opportunities without compromising on quality.

How Much Does Injection Molding Cost Per Hour?

The cost of injection molding per hour can vary depending on factors such as machine size, labor costs, energy consumption, and overhead expenses. Understanding these cost components is vital for businesses looking to optimize their production processes and minimize overall expenses.

One way to minimize costs in injection molding is by optimizing cycle times. This can be achieved by using high-speed machines, implementing efficient cooling systems, and fine-tuning the production process. By reducing the time it takes to produce each part, businesses can lower their overall production costs and increase output without compromising on quality.

Maximizing Efficiency in Injection Molding Processes

Maximizing efficiency in injection molding processes involves streamlining operations to reduce cycle times, minimize material waste, and improve overall productivity. By implementing lean manufacturing principles and investing in advanced technology like automated robotic systems, businesses can achieve significant cost savings while maintaining high-quality output.

Remember that maximizing efficiency doesn't mean cutting corners on quality. By partnering with a trusted provider of quality plastic injection molding services like Baoyuan, businesses can achieve cost-effective solutions without compromising on product excellence.

Ensuring Quality

When it comes to injection molding, maintenance is crucial to ensure the longevity and efficiency of the injection molding machine. Regular maintenance not only prevents unexpected breakdowns but also helps in maintaining the quality of the final plastic products. Proper cleaning, lubrication, and inspection of all components are essential for smooth and flawless operation.

Importance of Injection Molding Maintenance

Regular maintenance of an injection molding machine is essential to prevent costly downtime and maintain production efficiency. It involves scheduled checks, cleaning, and replacement of worn-out parts to ensure smooth operation. By investing in proper maintenance, businesses can prolong the lifespan of their equipment and reduce the risk of defects in their plastic products. Additionally, regular maintenance can also help identify potential issues before they escalate into major problems, saving both time and money in the long run. This proactive approach can also contribute to maintaining a safe working environment for employees, as well as ensuring compliance with industry regulations.

Quality Assurance in Injection Molding

Quality assurance plays a vital role in injection molding as it ensures that the final plastic products meet industry standards and customer expectations. This involves thorough inspection and testing at every stage of the manufacturing process, from raw material selection to finished product evaluation. Implementing quality control measures helps in identifying and rectifying any issues early on, preventing defective products from reaching customers.

Delivering High-Quality Plastic Products

The ultimate goal of injection molding is to deliver high-quality plastic products that meet or exceed customer requirements. To achieve this, it's essential to use top-grade materials, adhere to precise manufacturing processes, and maintain strict quality control standards throughout production. By focusing on delivering superior quality products, businesses can build a strong reputation for reliability and excellence in the market.

To further ensure the delivery of high-quality plastic products, it's important for businesses to invest in state-of-the-art technology and equipment. By staying updated with the latest advancements in injection molding technology, companies can improve efficiency, reduce production time, and minimize defects. This proactive approach not only enhances product quality but also demonstrates a commitment to innovation and continuous improvement.

Business Benefits

When exploring opportunities in the injection moulding business, it's important to understand the demand for custom injection molding services and the potential for growth in this industry. With the rise of innovative products and technologies, there is a continuous need for high-quality plastic injection molding solutions that cater to various industries.

Exploring Opportunities in Injection Moulding Business

The injection moulding business offers a wide range of opportunities for manufacturers looking to produce plastic parts and products on a large scale. With the increasing demand for custom injection molding services, businesses can capitalize on this trend by providing quality plastic injection molding solutions that meet the specific needs of their clients.

Key Considerations for Injection Molding Businesses

Key considerations for injection molding businesses include understanding custom injection molding cost, maximizing efficiency with the right injection molding machine, and implementing effective maintenance practices to ensure consistent quality. It's crucial to stay updated with industry trends and technologies to remain competitive in this dynamic market.

Understanding the unique requirements of each project is also essential for injection molding businesses. This includes being able to work closely with clients to determine the specific needs for their custom injection molding projects, whether it's material selection, design considerations, or production volume. By understanding and meeting these unique demands, injection molding businesses can build strong and lasting relationships with their clients, leading to repeat business and positive referrals.

Achieving Success in the Injection Molding Industry

To achieve success in the injection molding industry, businesses need to focus on delivering quality plastic products while keeping costs manageable. This involves optimizing production processes, ensuring efficient use of resources, and maintaining high standards of quality assurance throughout the entire manufacturing process. Additionally, staying updated with the latest technological advancements in injection molding equipment and techniques is crucial for remaining competitive in the market. Embracing automation and digitalization can streamline operations and improve overall efficiency, ultimately contributing to the success of a business in this industry.

Conclusion

At Baoyuan, we are committed to being your partner for quality injection molding solutions. With our expertise in designing molds and proficiency in injection molding, we ensure the highest standard of plastic products. Our focus on maximizing efficiency and minimizing costs will help you achieve cost-effective solutions without compromising on quality.

Baoyuan: Your Partner for Quality Injection Molding Solutions

With our dedication to providing quality plastic injection molding services, Baoyuan is the perfect partner for all your injection molding needs. Our team of experts ensures that every injection mold job meets the highest standards, delivering top-notch results for your business.

Maximizing Efficiency and Minimizing Costs

Understanding custom injection molding cost considerations is crucial for businesses looking to maximize efficiency and minimize costs. At Baoyuan, we offer insights into how much does injection molding cost per hour, helping you make informed decisions that benefit your bottom line.

The Future of Injection Molding Industry

As the industry evolves, it's essential to stay ahead of the curve with innovative solutions and cutting-edge technology. Baoyuan is at the forefront of this evolution, offering insights into the future of the injection molding industry and how businesses can adapt to thrive in this dynamic landscape.

By partnering with Baoyuan, you can harness the full potential of quality plastic injection molding services while staying ahead of industry trends. Let us help you navigate the complexities of injection moulding business and achieve success in this competitive market!