Introduction

Welcome to the fascinating world of plastic injection molded parts, where innovation meets precision engineering. In this introduction, we will explore the intricate process of injection molding and the myriad benefits it offers in manufacturing high-quality plastic products.

Introduction to Plastic Injection Molded Parts

Plastic injection molded parts are essential components in various industries, from automotive to consumer goods. These parts are created through the injection molding process, which involves melting plastic pellets and injecting them into a mold cavity to form the desired shape.

Understanding the Process of Injection Molding

The process of injection molding is a complex yet efficient method of producing plastic parts on a large scale. It requires meticulous attention to detail, from designing the mold to controlling temperature and pressure during the injection phase.

Benefits of Using Plastic Injection Molded Parts

The use of plastic injection molded parts offers numerous advantages, including cost-effectiveness, high production rates, and versatility in design and material options. This makes them an ideal choice for companies seeking durable and customizable components for their products.

Baoyuan's Expertise in Injection Molding

Baoyuan's expertise in plastic injection molding is attributed to its senior management and technical personnel, who possess extensive experience in the industry. With a dedicated team of professionals, Baoyuan ensures that every project is executed with precision and efficiency.

Baoyuan's Senior Management and Technical Personnel

The senior management at Baoyuan brings years of hands-on experience in plastic injection molding, overseeing every aspect of the production process to guarantee top-notch quality. Their technical personnel are highly skilled and well-versed in the latest advancements in injection moldable plastics, ensuring that all products meet industry standards. With a keen eye for detail and a commitment to innovation, Baoyuan's team is dedicated to staying ahead of the curve in the rapidly evolving field of plastic injection molding. This proactive approach allows them to anticipate and address any potential challenges before they impact production, resulting in efficient processes and superior end products that consistently exceed customer expectations.

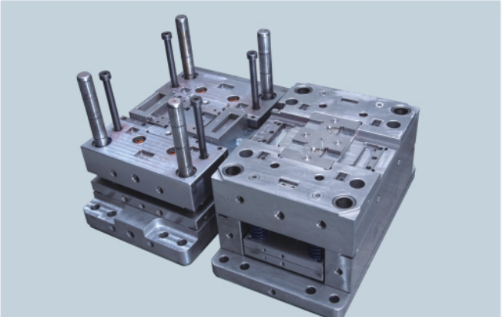

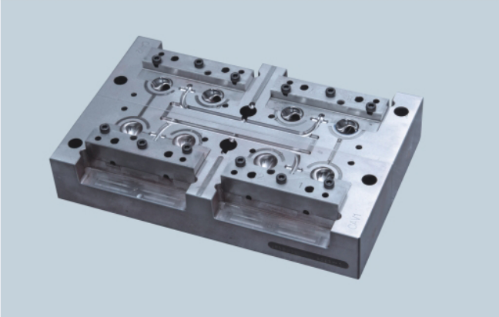

Software Design and Mold Opening

Baoyuan utilizes cutting-edge software design tools to create intricate molds for plastic injection molded parts. This advanced technology allows for precise customization and intricate detailing, resulting in flawless finished products. The mold opening process is streamlined and efficient, minimizing production time without compromising on quality.

Baoyuan's proficiency in producing single-color and double-color plastic products is a testament to their dedication to innovation and quality. With a keen eye for detail and a commitment to staying ahead of industry trends, Baoyuan consistently delivers plastic products that meet and exceed customer expectations. Their expertise in utilizing cutting-edge software design tools ensures that every mold is tailored to exact specifications, resulting in flawless finished products that stand out in the market.

Proficiency in Producing Single-color and Double-color Plastic Products

Baoyuan's proficiency extends to producing both single-color and double-color plastic products with utmost precision. Their expertise lies not only in standard plastic molding but also in creating innovative double-color designs that cater to diverse client needs. By staying at the forefront of technological advancements, Baoyuan is able to offer cutting-edge solutions that set them apart from their competitors. This commitment to innovation allows them to consistently deliver high-quality products that exceed customer expectations.

With a strong focus on leveraging technology and expertise, Baoyuan stands out as a leader among plastic molding companies, offering unparalleled quality and innovation in every project they undertake.

Finding Cost-Effective Plastic Injection Molding Companies

When researching plastic molding companies for your project, it's essential to consider their experience and track record in producing high-quality plastic injection molded parts. Look for companies with a proven history of delivering top-notch products and services to ensure your project's success.

Comparing pricing and quality is crucial when selecting a plastic molding company. While cost-effectiveness is important, it should not come at the expense of quality. Seek out companies that offer competitive pricing without compromising on the quality of their plastic injection molding processes and products.

Assessing the capabilities and technology of potential plastic molding companies is vital to determine if they can meet your project requirements. Look for companies that have state-of-the-art machinery, advanced technologies, and a skilled workforce capable of handling various moldable plastics for injection molding.

Researching Plastic Molding Companies

When researching plastic molding companies, consider their expertise in producing high-quality plastic injection molded parts. Look for customer reviews, case studies, and testimonials to gauge their reputation in the industry.

In addition to evaluating a plastic molding company's expertise and reputation, it's important to compare pricing and quality. While cost is a significant factor, it should not come at the expense of quality. Look for companies that offer competitive pricing without compromising on the quality of their products. It's also worth considering any additional services or perks that may be included in the pricing, such as design assistance or expedited production options.

Comparing Pricing and Quality

When considering pricing and quality among different injection molding companies, it's important to also take into account their capabilities and technology. A company with state-of-the-art equipment and advanced technology may be able to offer higher quality products at a competitive price. By assessing the capabilities of each company, you can ensure that they have the expertise and resources to meet your specific requirements, resulting in a superior end product. Additionally, understanding the technology used by each company can give you insight into their innovation and commitment to producing high-quality plastic molded products.

Assessing Capabilities and Technology

Assessing the capabilities and technology of potential plastic molding companies involves evaluating their production facilities, equipment, and expertise in handling various moldable plastics for injection molding processes.

After evaluating the production facilities, equipment, and expertise of potential plastic molding companies, it's important to consider their track record in delivering high-quality products on time. This can be determined by reviewing their client testimonials, case studies, and industry certifications. Additionally, assessing their ability to handle complex projects and provide innovative solutions is crucial for ensuring a successful partnership. By thoroughly examining these aspects, you can confidently select a plastic molding company that aligns with your specific needs and expectations.

Now that you've gained insight into finding cost-effective plastic injection molding companies let's move on to Tips for Working with a Plastic Molding Company.

Tips for Working with a Plastic Molding Company

Communicating Your Requirements Clearly

When working with a plastic molding company, it's crucial to clearly communicate your needs and expectations. Whether it's the specific design, material requirements, or production timeline, effective communication ensures that the final product meets your standards. By providing detailed information and being open to feedback, you can establish a productive working relationship with the molding company. To ensure that your requirements are clearly understood, consider creating visual aids such as sketches or 3D models to illustrate your vision. This can help eliminate any potential misunderstandings and ensure that everyone is on the same page from the outset.

Providing Detailed Technical Specifications

To avoid any misunderstandings or errors in the manufacturing process, it's essential to provide comprehensive technical specifications for your plastic injection molded parts. This includes detailed drawings, material requirements, dimensional tolerances, and any specific surface finish or texture requirements. Clear technical specifications help the molding company understand your exact needs and produce high-quality parts that meet your standards.

To further ensure the success of your plastic injection molding project, it's important to communicate openly and regularly with the molding company. This ongoing dialogue allows for any necessary adjustments or clarifications to be made to the technical specifications, ultimately leading to a smoother manufacturing process and a higher-quality end product. By establishing a collaborative partnership with the molding company, you can work together to address any challenges or issues that may arise, fostering a long-term relationship built on trust and mutual understanding.

Establishing a Long-term Partnership

Instead of treating the plastic molding company as just another supplier, consider building a long-term partnership based on mutual trust and collaboration. By fostering a strong relationship with the molding company, you can benefit from their expertise in injection moldable plastics and their ability to offer innovative solutions for your projects. A long-term partnership also allows for smoother communication and better understanding of each other's capabilities.

Building a long-term partnership with a plastic molding company also opens the door for potential cost savings and improved efficiency. With a strong relationship in place, the molding company may be more willing to provide discounts or prioritize your projects, ultimately leading to cost savings for your business. Additionally, by working closely with the molding company, you can streamline processes and reduce lead times, ultimately improving the overall efficiency of your production operations.

Quality Assurance in Plastic Injection Molding

As a critical aspect of the plastic injection molding process, ensuring consistent product quality is paramount. By using high-quality raw materials and precision-controlled machinery, plastic molding companies can guarantee the uniformity of their injection molded parts. This results in reliable and durable products that meet industry standards and customer expectations.

Ensuring Consistent Product Quality

To maintain consistent product quality, plastic injection molding companies implement rigorous quality control measures at every stage of production. This includes thorough material testing, precise mold design, and strict adherence to manufacturing standards. By prioritizing consistency, these companies can deliver injection molded parts that exhibit uniformity in dimensions, surface finish, and mechanical properties.

Testing and Inspection Processes

Testing and inspection processes play a crucial role in upholding the quality of plastic injection molded parts. Through comprehensive testing methods such as dimensional analysis, material property testing, and performance evaluations, manufacturers can identify any deviations or defects in the finished products. Additionally, meticulous inspection procedures ensure that only flawless parts are approved for packaging and delivery to customers.

Addressing Quality Issues

In the event of quality issues arising with plastic injection molded parts, reputable molding companies have established protocols for swift resolution. This may involve conducting root cause analysis to identify the source of the problem, implementing corrective actions to rectify it, and instituting preventive measures to mitigate future occurrences. By addressing quality issues proactively, these companies uphold their commitment to delivering superior products.

By prioritizing consistent product quality through stringent testing processes and proactive issue resolution strategies, plastic molding companies demonstrate their dedication to delivering reliable injection molded parts that meet industry standards and customer expectations.

Future Trends in Plastic Injection Molding

As the demand for plastic injection molded parts continues to grow, advancements in injection moldable plastics are on the rise. Manufacturers are constantly developing new materials with enhanced properties, such as improved strength, durability, and heat resistance. These innovations allow for the production of more complex and intricate plastic components, catering to a wide range of industries.

Advancements in Injection Moldable Plastics

With the increasing focus on sustainability, sustainable practices in injection molding have become a key trend in the industry. Many plastic molding companies are adopting eco-friendly processes and materials to minimize their environmental impact. This includes utilizing biodegradable or recycled plastics, reducing waste through efficient manufacturing techniques, and implementing energy-saving initiatives throughout the production process.

Sustainable Practices in Injection Molding

Emerging technologies in the plastic injection molding industry are revolutionizing the way products are designed and manufactured. From 3D printing of molds to advanced automation and robotics on the production floor, these cutting-edge technologies are streamlining processes, improving precision, and reducing lead times. Additionally, digital integration and smart manufacturing solutions are enhancing overall operational efficiency.

Emerging Technologies in the Industry

In conclusion, staying abreast of future trends is crucial when selecting a plastic molding company to partner with for your projects. By embracing advancements in injection moldable plastics, sustainable practices in injection molding, and emerging technologies in the industry, you can ensure that your products are not only of high quality but also environmentally friendly and produced with state-of-the-art methods.

Conclusion

In the competitive world of plastic injection molding, choosing the right partner is crucial for success. Look for a plastic molding company that has a proven track record in producing high-quality plastic injection molded parts. Ensure that they offer cost-effective solutions without compromising on quality. Embrace innovation by partnering with a company that stays ahead of the curve in injection moldable plastics and emerging technologies.

Choosing the Right Plastic Injection Molding Partner

When selecting a plastic molding company, prioritize expertise in injection molding and a strong portfolio of successful projects. Look for a partner with extensive experience in producing a wide range of plastic injection molded parts to ensure they can meet your specific needs.

Ensuring Quality and Cost-effectiveness

Quality assurance is paramount in plastic injection molding, so it's essential to work with a company that prioritizes consistent product quality through rigorous testing and inspection processes. At the same time, strive for cost-effectiveness by comparing pricing and capabilities among different injection molding companies.

Embracing Innovation in Injection Molding

Stay ahead of the competition by partnering with an injection moldable plastics expert that embraces sustainable practices and adopts emerging technologies in the industry. By working with an innovative plastic molding company, you can benefit from cutting-edge solutions and stay at the forefront of market trends.