Introduction

When it comes to creating plastic products, plastic injection molding creating plastic products, plastic injection moldings are the go-to method for manufacturers. This process involves injecting molten plastic into a mold, allowing it to cool and solidify into the desired shape. Custom injection molding is crucial for businesses looking to create unique, tailor-made plastic products that meet specific requirements. At Baoyuan, we are experts in plastic injection molding, offering top-notch services and solutions for all your injection molding needs.

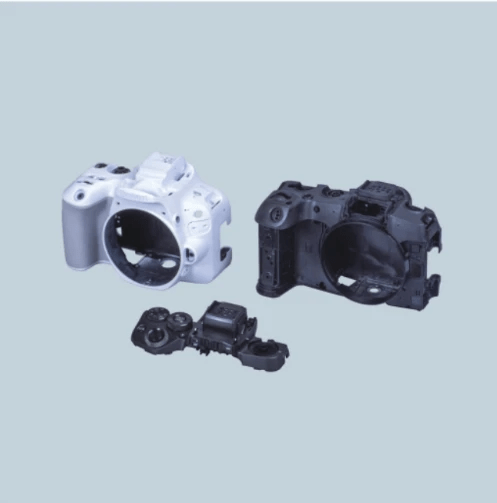

Understanding Plastic Injection Mould

Plastic injection molds are the tools used to produce a wide range of plastic products through the injection molding. These molds are designed with precision and expertise to ensure that the final product meets all quality standards and specifications.

Custom injection molding is essential for businesses looking to create unique and innovative plastic products. By customizing the design of injection molds, companies can ensure that their products stand out in the market and meet specific customer demands. This level of customization allows for greater flexibility in product design and functionality, giving businesses a competitive edge in their respective industries.

Importance of Custom Injection Molding

Custom injection molding allows businesses to create unique, tailor-made plastic products that cater to specific needs and requirements. This level of customization sets businesses apart from their competitors and allows for greater flexibility in product design.

Custom injection molding allows for unique product design and enables businesses to create complex shapes and intricate details that would be difficult or impossible to achieve with other manufacturing processes. This level of precision and attention to detail can result in higher-quality products that meet the exact specifications of the customer, leading to increased customer satisfaction and loyalty. Additionally, custom injection molding can help businesses reduce production costs by minimizing material waste and optimizing the manufacturing process.

Baoyuan: The Expert in Plastic Injection Mould

At Baoyuan, we have established ourselves as leaders in plastic injection molding. With our state-of-the-art facilities and expert team, we are dedicated to providing top-quality custom injection molding solutions that exceed our clients' expectations. Our commitment to innovation and continuous improvement sets us apart from the competition, allowing us to offer cutting-edge solutions for even the most complex projects. From design to production, we prioritize precision and efficiency, ensuring that every product meets the highest quality standards.

The Basics of Injection Molding

Plastic injection molding is a versatile process that involves melting plastic pellets and injecting them into a mold cavity. The molten plastic then cools and solidifies, taking the shape of the mold cavity. This method is widely used for producing various plastic products, from small components to large items.

The Process of Plastic Injection Molding

Injection molding is a manufacturing process that transforms plastic pellets into finished products. This process involves several key steps:

- Plastic Melting: Plastic pellets are heated until they reach a molten state.

- Injection: The molten plastic is injected into a mold cavity under high pressure.

- Cooling and Solidification: The plastic cools and solidifies within the mold, taking on its shape.

- Ejection: The finished product is ejected from the mold.

This efficient method allows for the rapid production of intricate plastic items with high precision.

Key Components of Injection Molding

Key components in injection molding include the mold, which determines the shape and features of the final product; the clamping unit, which is responsible for securely holding the mold in place during injection; and the injection unit, which melts and injects the plastic into the mold cavity. Each component plays a crucial role in ensuring high-quality output. In addition to these key components, other important elements of injection molding include temperature control systems to regulate the melting and cooling of the plastic and automated ejection systems to remove the finished product from the mold safely. These additional features contribute to efficient and consistent production processes.

Baoyuan’s Technological Expertise

Baoyuan excels at leveraging cutting-edge technology to enhance every stage of injection molding. From advanced machinery to innovative materials, Baoyuan’s technological expertise ensures efficient production processes and superior-quality output.

Baoyuan's technological expertise extends to the design and development of injection molds. Our engineers utilize state-of-the-art software and simulation tools to create intricate and precise mold designs. By leveraging advanced 3D modeling and analysis, we ensure that every aspect of the mold is optimized for maximum efficiency and durability. This attention to detail results in molds that deliver consistent, high-quality output throughout production.

Designing the Injection Mould

Software Utilization in Mould Design

Baoyuan is committed to delivering high-precision plastic injection molds through innovative software.

Our design process incorporates the following key elements:

- Advanced CAD/CAM software: Our skilled engineers utilize state-of-the-art software to create intricate and precise mold designs tailored to our clients' needs.

- Seamless collaboration: Our software facilitates efficient communication and client collaboration, allowing real-time feedback and adjustments throughout the design process.

- Optimized efficiency: By leveraging software, we streamline the design process, minimize errors, and reduce turnaround times, ensuring client satisfaction.

Baoyuan delivers exceptional mold designs that meet and exceed our clients' expectations through this software-driven approach.

Baoyuan's Senior Management and Technical Personnel

Our team at Baoyuan consists of experienced senior management and technical personnel who bring a wealth of knowledge and expertise to the table. With years of hands-on experience in injection molding, our professionals are adept at navigating complex design challenges and delivering high-quality custom molds.

Precision and Quality Assurance in Mould Design

We prioritize precision and quality assurance in every step of the mold design process. Our meticulous attention to detail ensures that each plastic injection mold is flawlessly crafted to produce consistent, high-quality plastic products for our clients.

Mold Opening and Injection Molding

Baoyuan's proficiency in mold opening becomes apparent as we move forward in plastic injection molding. With years of experience and technical expertise, Baoyuan ensures smooth and efficient mold opening, setting the stage for flawless injection molding.

Baoyuan’s Proficiency in Mold Opening

Baoyuan's team of skilled technicians and engineers are well-versed in the intricacies of mold opening. Their attention to detail and precision allows for seamless operation, minimizing downtime and maximizing productivity in the injection molding process.

Baoyuan's proficiency in mold opening extends beyond just technical expertise. Their team is also known for their innovative problem-solving skills, allowing them to address any issues that may arise during injection molding quickly. This proactive approach ensures smooth operation and helps prevent potential setbacks, ultimately saving time and resources. Baoyuan's technicians and engineers can deliver consistent, high-quality client results by staying ahead of the curve.

Injection Molding Process

Once the mold is opened, Baoyuan's injection molding process begins with precision and accuracy. The plastic material is injected into the mold cavity under high pressure, ensuring that every detail of the product design is faithfully replicated with exceptional quality. This meticulous attention to detail sets Baoyuan apart in the industry, as they specialize in producing single-color and double-color products with unparalleled expertise. Whether a simple, monochromatic item or a more complex dual-tone piece, Baoyuan has the technology and know-how to deliver flawless results every time.

Baoyuan's Specialization in Single-color and Double-color Products

Baoyuan takes pride in its specialization in single- and double-color products through injection molding. Whether a simple or complex design, our advanced technology and expertise guarantee superior results for all plastic molding needs.

Baoyuan's specialization in single-color and double-color products through injection molding sets us apart as a leader in the industry. Our state-of-the-art technology allows us to easily handle even the most complex designs, ensuring that our clients receive top-notch results every time. Whether a simple prototype or a large-scale production run, Baoyuan is committed to delivering high-quality plastic molding solutions for all your needs.

Quality Assurance in Injection Moulding

Regarding plastic injection molds, Baoyuan is committed to ensuring the highest quality of every product. With a team of experienced professionals and state-of-the-art technology, Baoyuan guarantees precision and consistency in all plastic products.

Baoyuan's Commitment to Quality Assurance

Baoyuan understands the importance of quality assurance in injection molding. They adhere to strict quality control measures at every process stage, from design to production, to ensure that the final product meets the highest standards.

Baoyuan's dedication to quality assurance extends beyond the manufacturing process. They invest in state-of-the-art technology and equipment to ensure precision and consistency in their plastic products. Using advanced tools and machinery, Baoyuan can guarantee that each item meets the exact specifications and requirements, delivering reliable and high-quality results every time.

Ensuring Consistency in Plastic Products

With custom injection molding, Baoyuan ensures consistency in plastic products by carefully monitoring and controlling every aspect of the manufacturing process. This results in products that are uniform in quality and performance, meeting or exceeding customer expectations.

In addition to closely monitoring the manufacturing process, Baoyuan invests in state-of-the-art technology and equipment to ensure consistency in plastic products. By utilizing advanced machinery and tools, the company can maintain precise control over every step of production, resulting in high-quality and reliable products. This commitment to technological innovation further demonstrates Baoyuan's dedication to meeting customer expectations.

Key Factors in Quality Control

Baoyuan's commitment to producing high-quality plastic products is evident in its robust quality control process. Key factors contributing to Baoyuan's success include:

- Advanced Machinery: Investment in cutting-edge technology ensures efficient and precise production, resulting in superior injection molds.

- Skilled Technicians: A team of highly trained professionals oversees the production process, guaranteeing adherence to stringent quality standards.

- Rigorous Testing Protocols: Comprehensive testing at every stage of production identifies and rectifies defects, ensuring that only the highest-quality products reach the market.

By diligently focusing on these elements, Baoyuan consistently delivers exceptional plastic products that exceed customer expectations.

Baoyuan: Your Trusted Injection Molding Partner

The Future of Plastic Molding

As technology advances, the future of plastic molding looks promising with more efficient processes and innovative materials. Custom injection molding will play a significant role in meeting the diverse needs of various industries, driving the demand for high-quality injection molds. With advancements in 3D printing and digital design capabilities, injection molding partners can offer faster prototyping and production cycles, reducing time-to-market for new products. Additionally, using sustainable materials and environmentally friendly manufacturing processes will be a key focus for injection molding partners in the future, aligning with the growing demand for eco-friendly solutions across industries.

Choosing the Right Injection Moulding Partner

When selecting an injection molding partner, it's crucial to consider their expertise, technological capabilities, and commitment to quality. Baoyuan stands out as a reliable partner with its extensive experience, state-of-the-art facilities, and dedication to delivering exceptional results in plastic injection molding.

With an unwavering commitment to quality and customer satisfaction, Baoyuan has established itself as a leader in the injection molding industry. Their team of skilled professionals is dedicated to delivering exceptional results, ensuring that every project meets the highest standards. Additionally, Baoyuan's state-of-the-art facilities and advanced technological capabilities enable them to tackle even the most complex plastic injection molding challenges easily.

With Baoyuan's proven track record in custom injection molding, precision mold design, and quality assurance, you can trust them to bring your plastic molding projects to life. Their expertise in injection molds ensures you receive top-notch products that meet your specifications and exceed your expectations.

By choosing Baoyuan as your injection molding partner, you can rest assured that your projects are in capable hands. As a leading provider of plastic injection mold solutions, Baoyuan is committed to delivering superior results that meet the highest standards of quality and precision.