Introduction

Understanding Plastic Injection Mold Costs

Plastic injection molds are essential tools in the production of various plastic components, but their costs can vary significantly based on several factors. To answer How much does it cost to make a plastic injection mould? one must consider not only the materials and labor involved but also the complexity of the design and intended application. Gaining a clear understanding of these elements will help businesses make informed decisions regarding their investments in injection molding technology.

Factors Influencing Mold Pricing

Several factors influence mold pricing, including material selection, labor costs, and geographical location of production facilities. For instance, many companies wonder How much does injection molding cost in China? because they seek cost-effective solutions without compromising quality. Additionally, complexity plays a significant role; intricate designs generally lead to higher prices due to increased labor and precision requirements.

The Benefits of Injection Molding

Despite concerns about initial expenses—often leading to questions like Why are plastic injection molds so expensive?—the long-term benefits can outweigh these upfront costs significantly. Injection molding offers advantages such as high efficiency, repeatability, and reduced waste compared to other manufacturing methods. Ultimately, when considering How Much Does an Injection Mold Cost, it's essential to weigh these benefits against potential savings over time.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that involves creating parts by injecting molten plastic into a mold. This method allows for the mass production of complex shapes with high precision and repeatability. It’s widely used across various industries, from automotive to consumer goods, due to its efficiency and cost-effectiveness.

Basic Process Overview

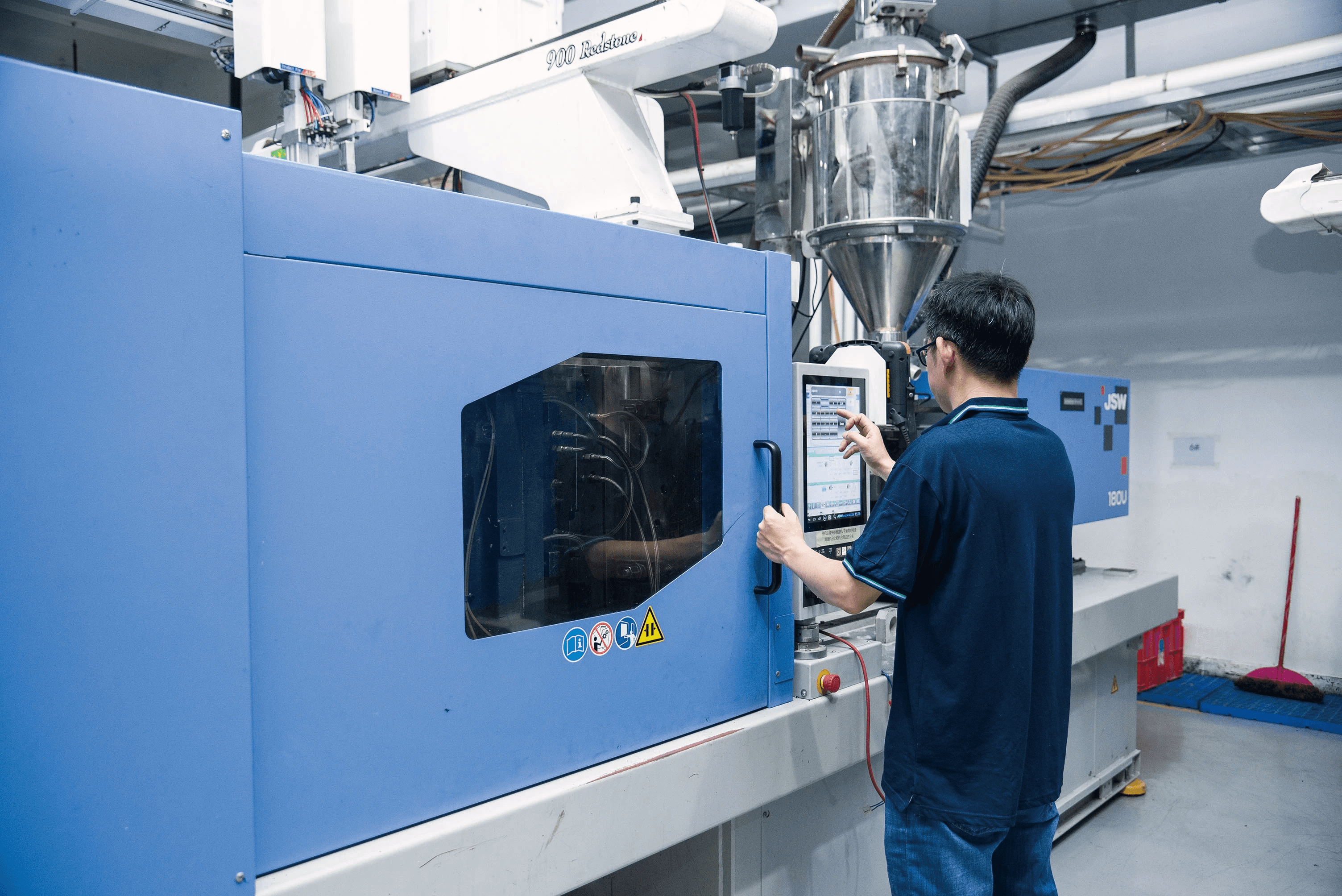

The plastic injection molding process begins with heating plastic pellets until they melt into a viscous liquid. This molten plastic is then injected into a carefully crafted mold under high pressure, where it cools and solidifies into the desired shape. Once the part has cooled sufficiently, the mold opens, and the finished product is ejected—a seamless operation that can produce thousands of identical pieces quickly.

Understanding how much does a plastic injection mold cost requires recognizing that this process isn't just about raw materials; it's also about precision engineering and time efficiency. The initial setup may seem costly, but it pays off when producing large volumes of parts at lower costs per unit. Hence, many manufacturers are keen to know how much does it cost to make a plastic injection mould for their specific needs.

Key Terminology Explained

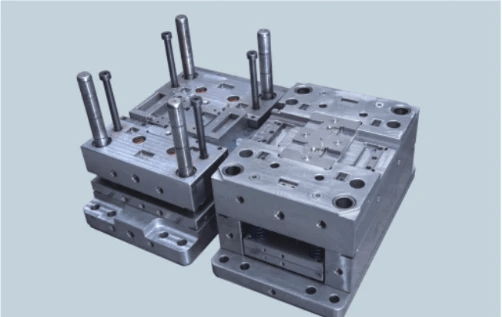

When discussing plastic injection molding, several key terms come into play: mold, runner, gate, and cycle time. The mold refers to the metal form that shapes the injected material; runner is the channel through which molten plastic flows; while the gate is where the material enters the cavity of the mold. Understanding these terms helps demystify why are plastic injection molds so expensive—each component must be precisely designed for optimal performance.

Another critical term is cycle time, which indicates how long it takes to complete one full cycle of injecting, cooling, and ejecting a part. Knowing these definitions allows businesses to better assess their production processes and costs associated with each step in making an injection mold or evaluating an injection mold cost calculator's output.

Applications of Injection Molding

Injection molding serves numerous industries due to its versatility in producing both simple and complex components efficiently. From automotive parts like dashboards and bumpers to household items such as containers and toys, almost every sector utilizes this technology in some capacity. Additionally, businesses often ask themselves how much does injection molding cost in China because many companies seek affordable manufacturing options while ensuring quality remains high.

Moreover, innovative applications continue emerging as materials evolve—think medical devices or intricate electronic housings that require precise specifications for functionality and safety standards compliance. As industries grow more competitive, understanding these applications can help companies navigate their investment decisions regarding molds effectively while keeping an eye on overall production costs associated with their projects.

How Much Does a Plastic Injection Mold Cost?

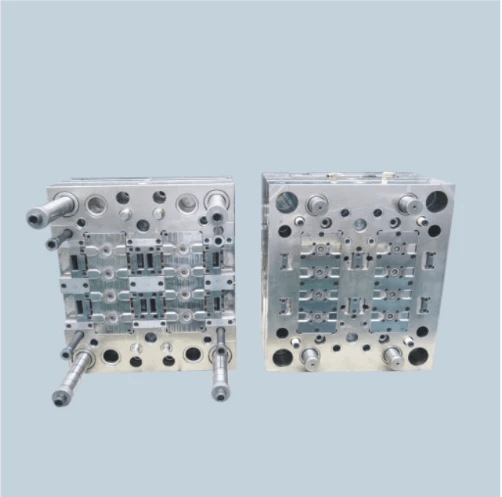

Breakdown of Cost Components

To get a clearer picture of the plastic injection mold cost, let's break down its components. First off, there's the initial design phase where engineers create detailed specifications; this can range from simple sketches to complex CAD models. Next up are the materials used for construction—steel or aluminum molds vary significantly in price—and finally, labor costs associated with machining and assembly must be factored in.

Additionally, you can't overlook overhead expenses such as maintenance of machinery and facility operations which also contribute to how much an injection mold costs overall. Each of these elements intertwines to create the total cost landscape for your project. So when you’re using an injection mold cost calculator, keep in mind that it’s not just about one single number; it's about understanding all these moving parts.

Comparing Costs Across Different Regions

Now that we’ve dissected what goes into determining how much does an injection mold cost, let’s take a look at regional variations. For instance, manufacturing costs in countries like China are often lower due to cheaper labor and material prices compared to Western countries like the USA or Germany. This leads many companies to ask: How much does injection molding cost in China?

However, while you might save upfront on production costs by outsourcing overseas, be wary of hidden expenses related to shipping and potential quality issues that could arise later on. Therefore, when evaluating your options across different regions for your plastic injection mold cost, consider both immediate savings and long-term implications.

Real-World Examples of Mold Pricing

To put things into perspective regarding how much does a plastic injection mold cost in practice, let’s look at some real-world examples. A simple two-cavity mold can range from $5,000 to $15,000 depending on its complexity and material choice. On the flip side of things—more intricate molds with multiple cavities or specialized features can easily climb into the $30k-$100k range.

Moreover, if you’re wondering why are plastic injection molds so expensive? It often boils down not just to materials but also engineering expertise required for high-quality production runs that meet stringent industry standards. Thus knowing specific examples helps clarify expectations when budgeting for your next project involving an injection mould.

Why Are Plastic Injection Molds So Expensive?

Material and Labor Costs Explained

To start, let’s break down material and labor costs, which are fundamental components of how much does a plastic injection mold cost? The materials used in creating molds—often high-grade steel or aluminum—are not cheap. These metals need to withstand high pressure and temperature during production, which drives up their price.

Labor costs also add significantly to the total expenses associated with making a plastic injection mould. Skilled technicians and engineers are required for both design and manufacturing processes, which can be time-consuming and complex. Therefore, when you ask yourself how much does it cost to make a plastic injection mould?, remember that quality craftsmanship comes at a premium.

The Role of Complexity in Pricing

Another factor influencing how much does an injection mold cost is its complexity. Simple designs may be less expensive due to fewer machining processes required, but intricate designs can skyrocket costs due to advanced engineering needs. Features like undercuts or multi-cavity setups require specialized techniques that increase both production time and material usage.

Moreover, complex molds often necessitate additional testing and adjustments before they can be used for mass production. This iterative process further inflates the overall expense of producing these molds. Consequently, if you're considering an investment in injection molding, understanding this complexity will help clarify why your initial quote might seem steep.

Long-Term Value vs. Initial Investment

Finally, let’s discuss long-term value versus initial investment—a critical consideration when evaluating how much does injection molding cost in China compared to other regions. While upfront costs for quality molds may seem daunting, they often yield substantial returns over time through efficient production runs and reduced waste.

Investing in high-quality molds means lower maintenance costs and longer service life; thus, you won't have frequent replacements eating into your budget later on. This perspective shifts your focus from immediate expenses to potential savings over time—a crucial aspect when using an injection mold cost calculator for budgeting purposes.

In conclusion, while it may be tempting to solely focus on upfront costs associated with plastic injection molds, consider all factors involved—including material quality, labor expertise, design complexity, and long-term benefits—to get a clearer picture of why these investments are worth making.

How Much Does Injection Molding Cost in China?

When considering the question, How much does injection molding cost in China?, it’s essential to recognize the various factors that contribute to the overall plastic injection mold cost. The significant cost benefits associated with manufacturing in China often make it an attractive option for businesses looking to optimize their production budgets. Lower labor costs, access to advanced technology, and economies of scale all play a role in making Chinese manufacturers competitive on the global stage.

Cost Benefits of Manufacturing in China

Manufacturing in China offers substantial cost benefits that can significantly reduce how much it costs to make a plastic injection mould. First and foremost, labor costs are generally lower compared to Western countries, which directly impacts the overall plastic injection mold cost. Additionally, China's well-established supply chains and infrastructure mean reduced lead times and lower shipping costs, enhancing savings for companies seeking efficient production solutions.

Moreover, Chinese manufacturers often have access to high-quality materials at competitive prices, allowing them to produce durable molds without breaking the bank. This combination of affordability and efficiency makes many businesses ask, How much does injection molding cost in China? as they seek reliable partners for their projects. Ultimately, these financial advantages can lead companies toward increased profitability while maintaining product quality.

Comparing Chinese Manufacturers

When evaluating different manufacturers in China for your injection molding needs, it's crucial to compare not only their pricing but also their capabilities and reputation within the industry. The question How much does an injection mold cost? may vary widely between suppliers based on factors such as experience level and technological expertise. Conducting thorough research into multiple manufacturers will help you find one that balances quality with affordability.

To make informed comparisons, utilize tools like an injection mold cost calculator that can provide estimates based on your specific project details or requirements. This way, you can assess whether a manufacturer’s quoted price aligns with market expectations or if they are inflating their rates unjustifiably. Remember that while some manufacturers may offer lower prices upfront, hidden costs or inferior quality could ultimately lead you back to asking why are plastic injection molds so expensive?

Quality Considerations for Offshore Production

While exploring how much does it cost to make a plastic injection mould overseas might seem appealing due to lower initial investments, it's critical not to overlook quality considerations when selecting a manufacturer in China. A low price should never come at the expense of craftsmanship; otherwise, you may end up facing costly rework or product failures down the line—defeating your purpose altogether!

Investing time into assessing potential suppliers’ quality assurance processes is vital before committing financially; this includes reviewing certifications and past client feedback related specifically to plastic injection mold costs incurred by other businesses working with them previously. Ensuring that your chosen manufacturer adheres strictly to international quality standards will safeguard against unexpected expenses later on—so you won’t be left wondering about those pesky additional charges!

In conclusion, understanding how much does injection molding cost in China involves examining both financial advantages and potential pitfalls associated with offshore production strategies while keeping an eye on quality control measures throughout each step of development.

Using an Injection Mold Cost Calculator

When it comes to determining the plastic injection mold cost, utilizing an injection mold cost calculator can be a game-changer. These tools simplify the often complex pricing structure into manageable figures, allowing you to estimate costs accurately and make informed decisions. With just a few inputs, you can gain insights into how much does a plastic injection mold cost based on your specific requirements.

Benefits of Cost Calculation Tools

Cost calculation tools for plastic injection molds offer multiple benefits that streamline your budgeting process. First off, they provide quick estimates that save time and effort compared to manual calculations or extensive research. Additionally, these calculators often factor in various components like material costs, labor rates, and production volume, giving you a comprehensive overview of how much does it cost to make a plastic injection mould.

Moreover, using an injection mold cost calculator allows for easy comparisons between different manufacturers or regions—critical when considering options like how much does injection molding cost in China. This capability helps you identify potential savings while ensuring you maintain quality standards throughout the production process.

Step-by-Step Guide to Using Calculators

Using an injection mold cost calculator is typically straightforward and user-friendly. Start by gathering all necessary details about your project: dimensions of the part, type of material required, expected production volume, and any specific design complexities that could influence pricing—this will give you accurate results regarding the question: How Much Does an Injection Mold Cost?

Once you've compiled this information, input it into the calculator fields as prompted. After submitting your data, review the breakdown provided by the tool; this will help clarify why are plastic injection molds so expensive based on factors such as complexity and material selection.

Finally, don't forget to compare results from different calculators if possible; each may use varying assumptions or formulas that could lead to different estimates for your plastic injection mold cost.

Best Online Resources for Cost Estimation

There are several online resources available where you can find reliable injection mold cost calculators tailored specifically for your needs. Websites like Protolabs or Xometry offer excellent tools designed with user-friendly interfaces that guide you through each step of estimating costs efficiently.

Additionally, forums and industry-specific websites often share insights on how much does it cost to make a plastic injection mould based on real-world experiences from professionals in the field. Engaging with these communities can also provide valuable context regarding trends in pricing and manufacturing practices worldwide.

Lastly, always check reviews or testimonials about any online resource before diving in; knowing which platforms deliver accurate information can save you time and ensure you're making well-informed decisions regarding your investment in an injection mold.

The Expertise of Baoyuan in Mold Production

When it comes to plastic injection mold cost, Baoyuan stands out as a premier provider in the industry. The company specializes in offering a comprehensive range of services that cater to various needs in mold production. From design and prototyping to full-scale manufacturing, Baoyuan ensures that clients receive top-notch solutions tailored to their specific requirements.

Overview of Baoyuan’s Services

Baoyuan provides an extensive suite of services designed to address all aspects of plastic injection molding. These include custom mold design, engineering support, and rapid prototyping, ensuring that customers can efficiently bring their ideas to life. By utilizing advanced technology and skilled craftsmanship, Baoyuan effectively manages the entire process while keeping an eye on how much it costs to make a plastic injection mould.

Team Experience and Technical Skills

The backbone of Baoyuan's success lies in its skilled team, boasting years of experience in the field of injection molding. This expertise is crucial when discussing how much does a plastic injection mold cost; knowledgeable professionals can navigate complexities that influence pricing effectively. With a focus on continuous training and development, the team is well-equipped with the latest technical skills required for innovative mold solutions.

Quality Assurance in Mold Production

Quality assurance is paramount at Baoyuan, especially considering why plastic injection molds are so expensive in many cases. The company employs rigorous testing protocols throughout the production process to ensure that every mold meets high standards before reaching customers. By implementing strict quality control measures, Baoyuan not only enhances durability but also helps clients understand how much does injection molding cost in China compared to other regions.

Conclusion

In the world of manufacturing, understanding the intricacies of plastic injection mold costs is crucial for making informed decisions. The relationship between design complexity and mold pricing cannot be overstated; a well-thought-out design can significantly affect how much does a plastic injection mold cost. As companies navigate these costs, they must balance initial investment against long-term value, ensuring they get the most out of their injection molding endeavors.

The Impact of Design on Mold Costs

Design plays a pivotal role in determining how much it costs to make a plastic injection mould. The more intricate the design, the higher the initial expenses due to increased material and labor requirements. Additionally, designs that are not optimized for manufacturability can lead to costly revisions down the line, making it essential to prioritize effective design strategies from the outset.

Navigating Cost Factors Effectively

To effectively manage plastic injection mold costs, businesses should consider various factors influencing pricing beyond just material and labor. Understanding regional differences in manufacturing can help answer questions like How much does injection molding cost in China? and whether offshore production aligns with quality expectations. Utilizing tools such as an injection mold cost calculator can also provide valuable insights into potential expenses and help streamline budgeting processes.

Final Thoughts on Injection Mold Investment

Ultimately, investing in an injection mold is not just about understanding How Much Does an Injection Mold Cost? but also recognizing its long-term benefits for production efficiency and product quality. While many may wonder why are plastic injection molds so expensive, it's important to see this expenditure as a strategic investment rather than just a cost burden. By taking time to analyze all aspects — from design considerations to geographic advantages — companies can make smarter decisions that yield substantial returns over time.