Introduction

In the world of manufacturing, injection molding stands out as a revolutionary process that allows for the mass production of intricate parts with high precision. Among various materials used in this technique, fiberglass injection molding has emerged as a popular choice due to its unique properties and versatility. But what exactly is fiberglass injection molding, and how does it differ from traditional methods?

Understanding the Basics of Injection Molding

Injection molding is a manufacturing process where molten material is injected into a mold to create specific shapes and designs. This method is widely used across industries for producing everything from automotive components to consumer goods. The ability to produce complex geometries at scale makes it an attractive option for manufacturers looking to optimize efficiency and reduce costs.

The Rise of Fiberglass Injection Molding

Fiberglass injection molding has gained traction as industries seek materials that offer strength without sacrificing weight. This rise can be attributed to fiberglass's impressive durability and resistance to environmental factors, making it suitable for various applications. As questions like Can fiberglass be injection moulded? continue to be answered positively, more companies are exploring this innovative approach.

Key Differences in Materials and Techniques

When comparing fiberglass with traditional plastic or metal options, several distinctions emerge in terms of performance and processing techniques. Fiberglass offers enhanced strength-to-weight ratios, but the techniques employed in fiberglass injection molding often require specialized equipment and expertise. Additionally, understanding What is fibre injection molding? helps clarify how these materials interact differently during the manufacturing process.

What is Fiberglass Injection Molding?

Fiberglass injection molding is a specialized manufacturing process that combines the unique properties of fiberglass with the efficiency of injection molding techniques. This method allows for the creation of complex shapes and durable parts, making it a popular choice across various industries. But what exactly sets fiberglass injection molding apart from traditional methods? Let’s dive into the details.

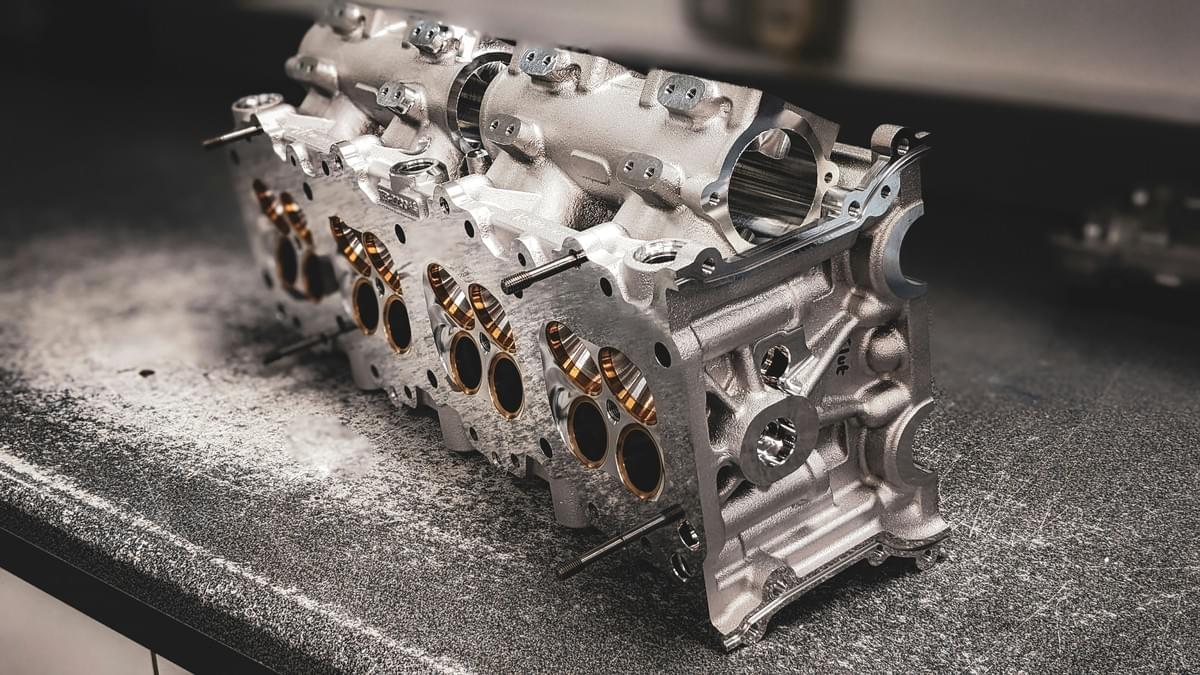

Defining Fiberglass Injection Molding

At its core, fiberglass injection molding refers to the process where fiberglass materials are injected into a mold to create specific shapes and components. Unlike standard plastic injection molding, which typically uses thermoplastics, this technique leverages the strength and lightweight nature of fiberglass composites. As industries seek stronger materials for their products, understanding what fiber injection molding entails becomes crucial for making informed decisions.

How Does Fiberglass Molding Work?

So, how does fiberglass molding work? The process begins with heating and mixing glass fibers with a resin to form a composite material that can be injected into molds under high pressure. Once cooled, this results in robust parts that exhibit exceptional strength-to-weight ratios—ideal for applications requiring durability without unnecessary bulkiness. By employing advanced technology and precise control over temperature and pressure, manufacturers can achieve intricate designs while maintaining high-quality standards.

Can Fiberglass Be Injection Moulded?

The question on many minds is: can fiberglass be injection moulded? The answer is a resounding yes! Fiberglass can indeed be molded using this innovative method, allowing manufacturers to produce components that benefit from both the resilience of fiberglass and the efficiency of modern injection techniques. This capability opens new doors for industries looking for alternatives to traditional materials when considering their options in terms of cost-effectiveness and performance.

Comparing Materials Used in Molding

When it comes to injection molding, the choice of material can significantly impact the quality, durability, and cost-effectiveness of the final product. Various materials are commonly used in this process, each with its unique properties and applications. Understanding these materials is crucial for making an informed decision, particularly when considering options like fiberglass injection molding.

Overview of Common Injection Molding Materials

Common materials used in injection molding include thermoplastics like ABS, polycarbonate, and nylon, as well as thermosetting plastics such as epoxy and polyurethane. These materials are favored for their versatility and ability to be molded into complex shapes with precision. However, fiberglass injection molding is gaining traction due to its enhanced strength-to-weight ratio and superior performance in demanding applications.

Fiberglass itself is a composite material made from glass fibers embedded in a resin matrix. This combination provides exceptional rigidity while remaining lightweight—attributes that make fiberglass an attractive option for various industries. The question often arises: Can fiberglass be injection moulded? Yes! Fiberglass can indeed be used in the injection molding process to create durable parts that withstand high stress and temperature variations.

What is the Strongest Material for Injection Molding?

When discussing strength in injection molding materials, it's essential to consider both tensile strength and impact resistance. While metals like aluminum or steel may reign supreme in terms of raw strength, they are not always practical for every application due to weight or cost constraints. In this context, fiberglass stands out as one of the strongest materials for injection molding that balances strength with lightweight properties.

Fiberglass offers impressive tensile strength while being significantly lighter than metals. Its ability to resist deformation under stress makes it ideal for applications requiring durability without added weight—think automotive parts or aerospace components! So when you're asking yourself what is the strongest material for injection molding? Remember that fiberglass could very well fit your needs if you require both toughness and lightness.

Pros and Cons of Fiberglass vs. Others

Like any material choice in manufacturing, opting for fiberglass injection molding comes with its own set of pros and cons compared to other options available on the market today. One significant advantage of using fiberglass is its excellent corrosion resistance; it holds up exceptionally well against environmental factors that might degrade other types of plastic or metal over time.

However, there are some downsides worth noting too—fiberglass can be more expensive than traditional plastics due to higher production costs associated with its specialized processing techniques (think about those fiberglass injection molding prices). Additionally, while it boasts impressive mechanical properties overall, certain formulations may not match specific performance characteristics offered by specialized thermoplastics designed explicitly for particular uses.

In summary, weighing these pros against cons will help you determine whether fiberglass fits your project requirements better than alternative materials available within the realm of injective modeling processes!

Cost Analysis: Fiberglass Injection Molding Price

When considering fiberglass injection molding, understanding the associated costs is crucial for any project. The price of fiberglass injection molding can vary significantly based on several factors, including material quality, complexity of the design, and production volume. Companies often seek to balance cost-effectiveness with the need for high-quality results, making it essential to analyze the overall fiberglass injection molding cost.

Understanding Fiberglass Injection Molding Cost

Fiberglass injection molding prices can be influenced by a range of elements that affect both manufacturing and material expenses. To comprehend what drives these costs, it's important to consider aspects such as mold creation, which can be a significant upfront investment. Additionally, ongoing production expenses like labor and machine operation contribute to the total cost of fiberglass injection molding.

Moreover, understanding how does fiberglass molding work is vital for estimating costs accurately; different techniques may require specialized machinery or processes that can impact pricing. For instance, while some manufacturers may use traditional methods that could be less expensive initially, advanced technologies might offer long-term savings through efficiency. Ultimately, grasping these nuances will help businesses make informed decisions regarding their projects.

Factors Influencing Pricing

Several key factors influence the pricing structure of fiberglass injection molding beyond just raw materials. One significant element is the complexity of the design; intricate parts often require more sophisticated molds and longer production times, leading to higher costs. Furthermore, volume plays an essential role—larger production runs typically reduce per-unit costs due to economies of scale.

Another important consideration is whether Can fiberglass be injection moulded? The answer is yes! However, not all types are created equal; certain formulations or reinforcements may lead to variations in price based on their performance characteristics and availability in the market. Additionally, fluctuations in market demand for specific materials can also cause shifts in pricing over time.

Cost Comparison with Other Materials

When evaluating fiberglass injection molding price against other materials used in similar applications, it’s clear that each option comes with its own set of advantages and drawbacks. For example, while metals might offer superior strength—often regarded as what is the strongest material for injection molding—they typically incur higher processing costs due to machining and finishing requirements compared to fiberglass options.

In contrast, plastics are often cheaper but lack some durability attributes found in fiberglass products; thus they may not always be suitable for demanding environments or applications requiring longevity. By comparing these various materials side-by-side regarding their respective strengths and weaknesses alongside their cost implications—businesses can better determine which option aligns best with their project goals.

Manufacturers in the Injection Molding Industry

The landscape of fiberglass injection molding is populated with manufacturers who are pushing the boundaries of technology and innovation. As industries increasingly recognize the benefits of fiberglass, these manufacturers are stepping up to meet demand with high-quality solutions. From small-scale operations to large corporations, each plays a crucial role in shaping the future of fiberglass injection molding.

Top Fiberglass Injection Molding Manufacturers

When it comes to fiberglass injection molding, several key players dominate the market. Companies like Owens Corning and Hexcel are renowned for their expertise in composite materials and advanced molding techniques. Additionally, emerging companies such as Composites One are also making significant strides, offering innovative products that answer the question: Can fiberglass be injection moulded? Their commitment to quality ensures that customers receive reliable and durable components.

These top fiberglass injection molding manufacturers have honed their processes to maximize efficiency while maintaining product integrity. They utilize cutting-edge technology and skilled craftsmanship to create molds that withstand rigorous applications. With a focus on sustainability and reducing waste, these companies are setting new standards within the industry.

Highlighting Baoyuan's Expertise in the Field

Baoyuan stands out as a prominent name among fiberglass injection molding manufacturers, known for its dedication to quality and innovation. This company specializes in producing high-performance components that cater to various industries, including automotive, aerospace, and consumer goods. By leveraging advanced technologies and materials science expertise, Baoyuan effectively answers how does fiberglass molding work?

Their production methods emphasize precision engineering while ensuring cost-effectiveness—an essential factor when considering fiberglass injection molding price. Baoyuan's ability to adapt quickly to market demands makes them a preferred partner for businesses looking for reliable solutions without compromising on quality or performance.

Innovations by Leading Manufacturers

The field of fiberglass injection molding is witnessing rapid innovations from leading manufacturers aiming to enhance product performance while reducing costs. New techniques such as automated fiber placement (AFP) allow for more efficient material usage while improving structural integrity—answering the question: What is fibre injection molding? These advancements not only streamline production but also contribute positively toward sustainability goals.

Moreover, research into hybrid materials combining traditional plastics with fiberglass is paving new avenues for enhanced strength and flexibility in molded products—prompting discussions about what is the strongest material for injection molding? As competition intensifies among manufacturers, continuous innovation will remain vital in meeting diverse customer needs across various sectors.

Applications and Use Cases

Fiberglass injection molding is making waves across various industries due to its versatility and strength. As companies seek innovative solutions, the demand for fiberglass injection molding is on the rise. From automotive to aerospace, this technique is proving to be a game-changer.

Industries Leveraging Fiberglass Injection Molding

Several sectors are capitalizing on the benefits of fiberglass injection molding. The automotive industry, for instance, utilizes this method for creating lightweight yet durable components that enhance fuel efficiency. Additionally, the construction sector employs fiberglass parts for their superior strength and resistance to environmental factors, making them ideal for structural applications.

In the aerospace industry, where weight reduction is crucial, fiberglass injection molding provides an optimal solution by producing strong and lightweight components. The electronics sector also benefits from this technology by manufacturing intricate parts that require precision and durability. With such diverse applications, it’s clear why many ask, “Can fiberglass be injection moulded?”—the answer being a resounding yes!

Real-World Examples of Successful Projects

There are numerous real-world examples showcasing the success of fiberglass injection molding in action. One notable project involved a major automotive manufacturer that used fiberglass components in their latest model's body panels—resulting in a significant reduction in overall vehicle weight while maintaining structural integrity. This not only improved fuel efficiency but also enhanced performance metrics.

Another example can be found in consumer goods; a company specializing in outdoor furniture utilized fiberglass injection molding to create stylish yet resilient chairs that withstand harsh weather conditions without compromising aesthetics or comfort. These projects highlight how effective fiberglass can be when molded into complex shapes through advanced techniques like fiber injection molding.

Future Trends in Fiberglass Applications

Looking ahead, the future of fiberglass injection molding appears bright with emerging trends set to reshape its applications further. Advancements in technology are leading to more efficient production processes that lower costs associated with fiberglass injection molding price points while enhancing quality control measures—making it even more appealing for manufacturers.

Sustainability is another trend driving innovation; as industries strive for greener practices, recycled materials are being integrated into fiberglass products without sacrificing performance or durability. This shift towards eco-friendly solutions will likely increase interest in what is the strongest material for injection molding as manufacturers seek sustainable alternatives.

As we witness these developments unfold, it's clear that understanding how does fiberglass molding work will become increasingly vital for businesses aiming to stay competitive in their respective markets.

Conclusion

In wrapping up our exploration of fiberglass injection molding, it’s clear that this technique is not just a passing trend but a robust method with significant advantages. We’ve delved into how fiberglass molding works and discovered that yes, fiberglass can indeed be injection moulded, allowing for versatile applications across various industries. Understanding the cost dynamics associated with fiberglass injection molding price also provides insight into its value proposition compared to other materials.

Summarizing Key Insights About Fiberglass Molding

Fiberglass injection molding combines the strength of fiberglass with the efficiency of modern manufacturing techniques, making it a standout choice for many projects. The process involves injecting molten resin mixed with glass fibers into a mold, resulting in durable parts that are lightweight yet incredibly strong. This method answers the question: what is fibre injection molding? It’s essentially a game-changer for those seeking high-performance materials without compromising on weight.

The Competitive Edge of Fiberglass Injection Molding

One of the most compelling aspects of fiberglass injection molding is its ability to produce parts that are not only strong but also resistant to environmental factors like moisture and chemicals. When asking what is the strongest material for injection molding, many would find themselves drawn to fiberglass due to its exceptional tensile strength and durability compared to traditional plastics or metals. Additionally, leading fiberglass injection molding manufacturers are constantly innovating, ensuring that this technique remains at the forefront of industrial applications.

Making the Right Choice for Your Project

When considering your options for manufacturing processes, evaluating fiberglass injection molding cost versus benefits can lead you toward smarter decisions for your project’s needs. With various factors influencing pricing—from material selection to mold complexity—it's crucial to weigh these against performance requirements and budget constraints. Ultimately, whether you’re looking at specific applications or pondering how does fiberglass molding work in practice, choosing this method could provide your project with an unparalleled edge in quality and efficiency.