Introduction

Are you looking for cost-effective plastic injection molding solutions? Look no further! In this guide, we'll explore the benefits of budget-friendly plastic injection molding, how to choose the right solution for your needs and gain a better understanding of the injection molding process.

The Benefits of Budget-Friendly Plastic Injection Molding

Cheap injection molding offers a surprising range of benefits beyond cost savings. This manufacturing method can streamline your production process and unlock a world of design possibilities.

Key advantages of cheap injection molding include:

- Reduced production costs: Enjoy significant savings compared to traditional manufacturing methods.

- Faster turnaround times: Bring your products to market quicker and respond to changing demands efficiently.

- Design flexibility: Create intricate and complex shapes without limitations, giving your products a unique edge.

- High-quality results: Achieve professional-grade finishes and precision at affordable prices.

Don't let budget constraints hinder your product development. Cheap injection molding empowers you to produce exceptional products without breaking the bank.

Choosing the Right Plastic Injection Molding Solution

When it comes to mold plastic injection, selecting a reliable and experienced provider who can deliver top-notch results at a reasonable price is crucial. You can find the perfect fit for your project requirements by exploring various cheap injection molding options. It's important to consider the provider's track record and customer reviews to ensure you work with a reputable company. Additionally, look for a supplier that offers customization options and can accommodate any special requests or unique specifications for your project. This will ensure you get the best solution for your plastic injection molding needs.

Understanding the Injection Molding Process

To make informed decisions about plastic injection molding near me, you must have a solid grasp of the injection molding process. Understanding each step, from material selection to final product inspection, will help you maximize efficiency and quality.

The Baoyuan Advantage in Plastic Injection Molding

Baoyuan stands out in plastic injection molding due to its senior management and technical expertise. With years of experience, the Baoyuan team deeply understands the intricacies of injection molding, ensuring that every project is handled with precision and care.

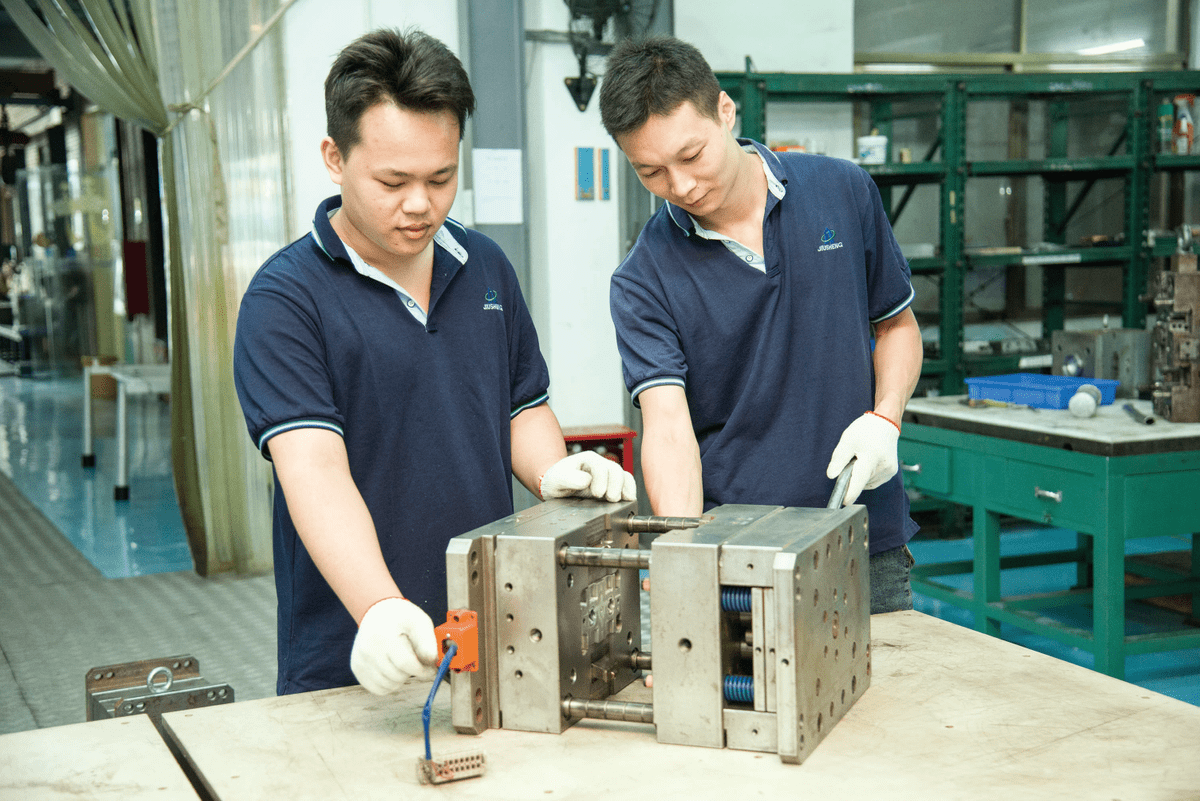

Senior Management and Technical Expertise at Baoyuan

The senior management team at Baoyuan brings a wealth of knowledge to the table, allowing for strategic decision-making and effective leadership. Their technical expertise ensures that each plastic injection molding project is executed flawlessly, meeting the highest quality standards in the industry.

In addition to their strategic decision-making and technical expertise, the senior management team at Baoyuan also excels in designing and opening molds for plastic injection molding projects. Their proficiency in mold design ensures that each product is tailored to meet the client's specific needs. In contrast, their expertise in opening molds guarantees smooth and efficient production. This attention to detail and precision sets Baoyuan apart as a leader in the industry, consistently delivering top-quality results.

Proficiency in Designing and Opening Molds

Baoyuan's proficiency in designing and opening molds sets them apart from their competitors. Their skilled technicians can create customized molds tailored to specific project requirements, resulting in efficient and cost-effective production processes. This attention to detail ensures that the plastic products manufactured by Baoyuan meet high-quality standards, providing customers with durable and reliable solutions for their needs. By prioritizing precision in mold design and opening, Baoyuan can deliver consistent excellence in its plastic products, earning it a reputation for reliability and performance in the industry.

Quality Assurance of Plastic Products at Baoyuan

Quality assurance is paramount at Baoyuan, with stringent measures in place to ensure that all plastic products meet strict quality standards. Through rigorous testing and inspection protocols, Baoyuan guarantees its clients receive only top-notch plastic molding products.

At Baoyuan, quality assurance is a process and a commitment to excellence. Every step of the production and manufacturing process is carefully monitored to ensure the final plastic products meet the highest standards. From material selection to mold design and production, Baoyuan leaves no stone unturned in its quest for perfection.

Exploring Cheap Injection Molding Options

When finding affordable plastic injection molding services, it's important to consider the quality of the end product. Cheap injection molding doesn't have to mean sacrificing quality. Look for a company that offers cost-effective solutions without compromising the integrity of the moldable plastics.

Affordable Plastic Injection Molding Services

Affordable plastic injection molding services are readily available for businesses looking to keep costs down without compromising quality. Look for a provider that offers competitive pricing without sacrificing precision and efficiency in the injection molding process. With the right partner, you can achieve high-quality results at a fraction of the cost.

When searching for affordable plastic injection molding services, it's important to consider the provider's experience and track record. A reputable company with a history of successful projects and satisfied clients is likelier to deliver high-quality results at a competitive price. By choosing a seasoned partner in injection molding, you can benefit from their expertise and industry knowledge, ensuring that your project is completed efficiently and to the highest standards.

Cost-effective Injection Moldable Plastics

Cost-effective injection-moldable plastics are essential for achieving budget-friendly plastic molding solutions. Seek out materials that offer durability and versatility while remaining affordable. By choosing the right injection-moldable plastics, you can produce high-quality products without breaking the bank.

Budget-Friendly Plastic Molding Solutions

When you partner with a reliable and experienced injection molding company, budget-friendly plastic molding solutions are within reach. Look for a provider that offers competitive pricing, efficient production processes, and a commitment to delivering top-notch results at an affordable price point.

Finding Quality Plastic Injection Molding Near Me

When looking for reliable injection molding services, it's crucial to consider the facility's proximity to your location. This ensures quick turnaround times and cost-effective shipping options. You can easily visit their facility for quality checks and consultations by choosing a nearby plastic injection molding company.

Locating Reliable Injection Molding Services

To locate reliable injection molding services near you, conduct a thorough online search and read customer reviews. Look for companies with a strong track record of delivering high-quality plastic products and excellent customer service. Additionally, consider contacting local industry associations for recommendations on trusted injection molding providers in your area.

After conducting your online search and reading customer reviews, it's important to consider your project's specific needs. Look for injection molding services that have experience producing the type of plastic products you require. Finding a company with a proven track record in your industry will ensure high-quality results, whether it's small, intricate components or large, durable parts.

Ensuring High-Quality Plastic Molding Products

Regarding ensuring high-quality plastic molding products, proximity plays a key role in maintaining stringent quality control standards. Visiting the manufacturing facility allows you to inspect the production process firsthand and communicate any specific requirements directly with the team. This level of oversight is crucial in guaranteeing that your plastic products meet your exact specifications.

Proximity also allows for more efficient troubleshooting and problem-solving. When issues arise during production, being nearby enables you to address any concerns and make necessary adjustments in real time quickly. This can help prevent costly delays and ensure that your plastic molding products are delivered on schedule without compromising quality.

The Importance of Proximity in Injection Molding

Proximity is a critical factor in successful injection molding, offering substantial benefits in both cost and efficiency. By partnering with a local plastic injection molding company, you can reap the following advantages:

- Cost Savings: Reduce shipping expenses and lead times significantly, optimizing your budget without compromising quality or precision.

- Efficient Communication: Facilitate open dialogue and quick decision-making through on-site visits, design consultations, and prototype inspections.

- Streamlined Production: Experience smoother operations and faster problem-solving due to improved communication and collaboration.

Choosing a local partner empowers you to achieve your project goals while maximizing your resources.

Understanding the Plastic Injection Molding Process

Plastic injection molding is a versatile and cost-effective manufacturing process that involves injecting molten plastic into a mold cavity. This process produces many complex plastic parts and products, making it an ideal solution for various industries.

The Basics of Injection Molding

The basic concept of injection molding involves heating plastic resin to a molten state and injecting it into a mold under high pressure. Once the plastic cools and solidifies, the mold opens, and the finished product is ejected. This process can create anything from small precision parts to large automotive components.

Key Steps in the Injection Molding Process

Injection molding is a manufacturing process used to create plastic parts by injecting molten material into a mold. The process typically involves four key stages:

- Clamping: The mold halves are securely closed together.

- Injection: Molten plastic resin is forced into the mold cavity under high pressure.

- Cooling: The plastic is allowed to solidify within the mold.

- Ejection: The mold opens, and the finished product is removed.

By carefully controlling these steps, manufacturers can produce a wide range of plastic products with high precision and efficiency.

Maximizing Efficiency in Plastic Injection Molding

Optimizing cycle times, minimizing material waste, and ensuring consistent part quality is essential to maximizing efficiency in plastic injection molding. This can be achieved through proper mold design, efficient machine operation, and precise control of processing parameters such as temperature and pressure.

Now that we've covered some basics about plastic injection molding let's explore Baoyuan's advantage in this field!

Advantages of Baoyuan's Injection Molding Machine

Baoyuan's state-of-the-art injection molding machine is a game-changer in the industry, offering advanced technology and precision in plastic molding. With cutting-edge features and capabilities, Baoyuan's machine ensures high-quality products and efficient production processes.

Baoyuan's State-of-the-Art Injection Molding Machine

Baoyuan's injection molding machine boasts state-of-the-art technology, incorporating the latest advancements in plastic injection molding. Its innovative design and functionality set it apart from traditional machines, delivering superior performance and reliability for all plastic molding needs.

Efficiency and Precision in Plastic Molding

The Baoyuan injection molding machine excels in efficiency and precision, allowing for the production of high-quality plastic products with minimal waste and maximum accuracy. Its advanced controls and monitoring systems ensure consistent results, making it a cost-effective choice for cheap injection molding solutions.

The Baoyuan Difference in Injection Molding Technology

With its commitment to innovation and excellence, Baoyuan has redefined the standards of injection molding technology. By prioritizing efficiency, precision, and cost-effectiveness, Baoyuan's machine offers a competitive advantage in the industry, making it the top choice for plastic injection molding needs.

Now that you have an insightful understanding of the advantages of Baoyuan's state-of-the-art injection molding machine let's explore cheap injection molding options and find quality plastic injection molding services near you.

The Baoyuan Commitment to Quality in Plastic Injection Molding

Budget-friendly plastic injection molding is the future of manufacturing, offering cost-effective solutions without compromising quality. With a wide range of cheap injection molding options and affordable plastic injection molding services, making informed decisions for your needs has never been easier. Baoyuan's commitment to quality in plastic injection molding ensures you get the best value for your money.

The Future of Budget-Friendly Plastic Injection Molding

As technology advances, the future of budget-friendly plastic injection molding looks promising. With innovations in cost-effective injection moldable plastics and state-of-the-art injection molding machines, manufacturers can expect even more affordable options without sacrificing quality.

Making Informed Decisions for Your Injection Molding Needs

When choosing the right plastic injection molding solution, consider factors such as proximity to reliable injection molding services and the efficiency of the injection molding process. By staying informed about the latest developments in plastic molding technology, you can make well-informed decisions that meet your specific needs.

Baoyuan's dedication to providing high-quality plastic products through its expertise in mold plastic injection and proficiency in designing molds sets it apart in the industry. Its state-of-the-art injection molding machine ensures efficiency and precision, making it a trusted partner for all your plastic molding needs.

With Baoyuan's expertise and commitment to quality, you can trust that your budget-friendly plastic injection molding needs will be met with excellence every time.