Introduction

In the world of manufacturing, understanding the cost of plastic injection molding is crucial for businesses looking to optimize their production processes. Plastic injection molding is not just a method; it’s a science that combines engineering and economics to create high-quality products efficiently. By grasping the various elements that contribute to injection molding costs, companies can make informed decisions when selecting plastic injection molding services.

Understanding Plastic Injection Molding Costs

The cost of plastic injection molding involves multiple factors, including tooling, materials, and labor. Initial investments in mold plastic injection can be significant, but they often lead to lower per-unit costs as production scales up. By analyzing these costs, manufacturers can better evaluate their options and choose the most efficient plastic injection moulding service for their needs.

Key Factors Affecting Injection Molding Prices

Several key factors influence the pricing structure of plastic injection molding services. The complexity of the design plays a major role; intricate designs may require more advanced molds and longer production times, thus increasing costs. Additionally, fluctuations in material prices and labor rates can directly impact the overall cost of plastic injection molding projects.

The Role of Material Selection

Material selection is one of the most significant aspects affecting the cost of plastic injection molding. Different types of injection moldable plastics come with varying price points and performance characteristics that can influence both initial expenses and long-term durability. Choosing the right material not only ensures product quality but also helps manage costs effectively throughout the lifecycle of your project.

What Is Plastic Injection Molding?

Plastic injection molding is a highly efficient manufacturing process used to produce a wide array of parts and components. This method involves injecting molten plastic into a pre-designed mold, where it cools and solidifies into the desired shape. Understanding the intricacies of this process is vital for anyone considering the cost of plastic injection molding for their projects.

Basics of the Injection Molding Process

At its core, injection molding begins with melting plastic pellets in a heated barrel until they reach a liquid state. Once melted, this material is injected under high pressure into a mold cavity, which is designed to form specific shapes and features. After cooling, the mold opens to release the finished product, making it a rapid and repeatable method ideal for high-volume production runs.

The efficiency of this process means that manufacturers can produce thousands of identical pieces quickly, reducing overall production time. However, it's essential to note that upfront costs can be significant due to tooling and design expenses associated with creating custom molds for injection moldable plastics. Thus, understanding these basics helps businesses anticipate both initial investments and long-term savings when utilizing plastic injection molding services.

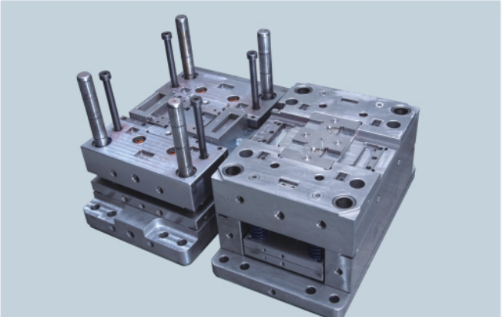

Types of Mold Plastic Injection

There are several types of molds used in plastic injection molding that cater to various production needs and budgets. The most common include single-cavity molds for low-volume production and multi-cavity molds designed for mass manufacturing where multiple parts are produced simultaneously from one cycle. Additionally, there are family molds that allow different parts to be produced together in one shot, optimizing efficiency further.

Each type has its own cost implications; for example, while single-cavity molds may have lower initial costs, they also lead to higher per-unit costs when producing large quantities compared to multi-cavity options. Furthermore, specialized molds like hot runner systems can reduce waste but come with increased complexity and expense upfront—definitely something worth considering when evaluating your options in plastic injection moulding service providers. Ultimately, selecting the right type of mold plays an integral role in balancing quality and cost-effectiveness in your projects.

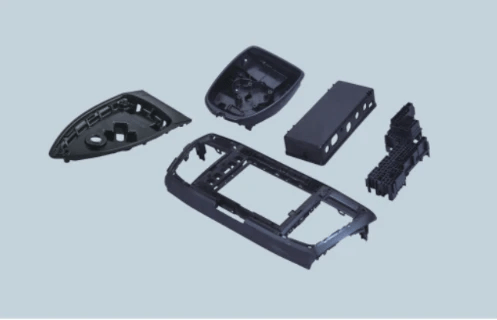

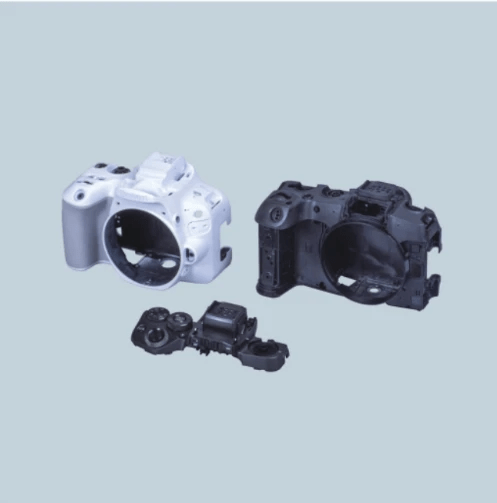

Common Applications of Injection Moldable Plastics

Injection moldable plastics are ubiquitous across numerous industries due to their versatility and durability. From automotive components like dashboards and bumpers to household items such as containers or toys—plastic injection molding caters to diverse applications that require precision engineering at scale. The ability to create complex geometries makes it particularly valuable in sectors such as electronics where intricate designs are often necessary.

Moreover, medical devices also benefit significantly from this process; many surgical tools or packaging materials utilize molded plastics because they can be easily sterilized and customized according to strict industry standards. As businesses continue seeking innovative solutions at competitive prices, understanding how different applications leverage the benefits of injection molding becomes crucial when assessing the cost of plastic injection molding services available today.

Breakdown of Costs in Plastic Injection Molding

When it comes to understanding the cost of plastic injection molding, it's essential to dissect the various components that contribute to the overall price. This breakdown will help you navigate the complexities of injection molding services and make informed decisions when selecting a plastic injection moulding service. By examining initial tooling, material costs, and labor expenses, you can gain a clearer picture of what affects your bottom line.

Initial Tooling and Design Expenses

The first significant expense in the cost of plastic injection molding is the initial tooling and design process. Creating a mold for plastic injection requires precision engineering, which can be quite costly depending on the complexity and size of your design. These upfront costs are often amortized over large production runs; thus, they become less burdensome per unit as production volume increases.

Investing in high-quality tooling ensures that your mold plastic injection performs efficiently throughout its lifecycle. Remember that cheaper options might save money initially but could lead to higher costs down the road due to frequent repairs or replacements. Therefore, understanding these initial expenses is crucial for anyone looking into plastic injection molding services.

Material Costs for Molding

Material selection plays a pivotal role in determining the cost of plastic injection molding. The type of resin or polymer used directly impacts both quality and price; premium materials may offer enhanced properties but come with increased costs. For instance, using specialized grades of injection moldable plastics can elevate product performance but also raises your overall expenditure.

Moreover, fluctuations in raw material prices can significantly affect your budget over time—keeping an eye on market trends is wise if you're planning long-term projects involving plastic injection moulding service. Choosing materials wisely not only influences immediate costs but also has implications for durability and functionality down the line. Thus, assessing material options is essential when calculating total expenses in this manufacturing process.

Labor and Production Overheads

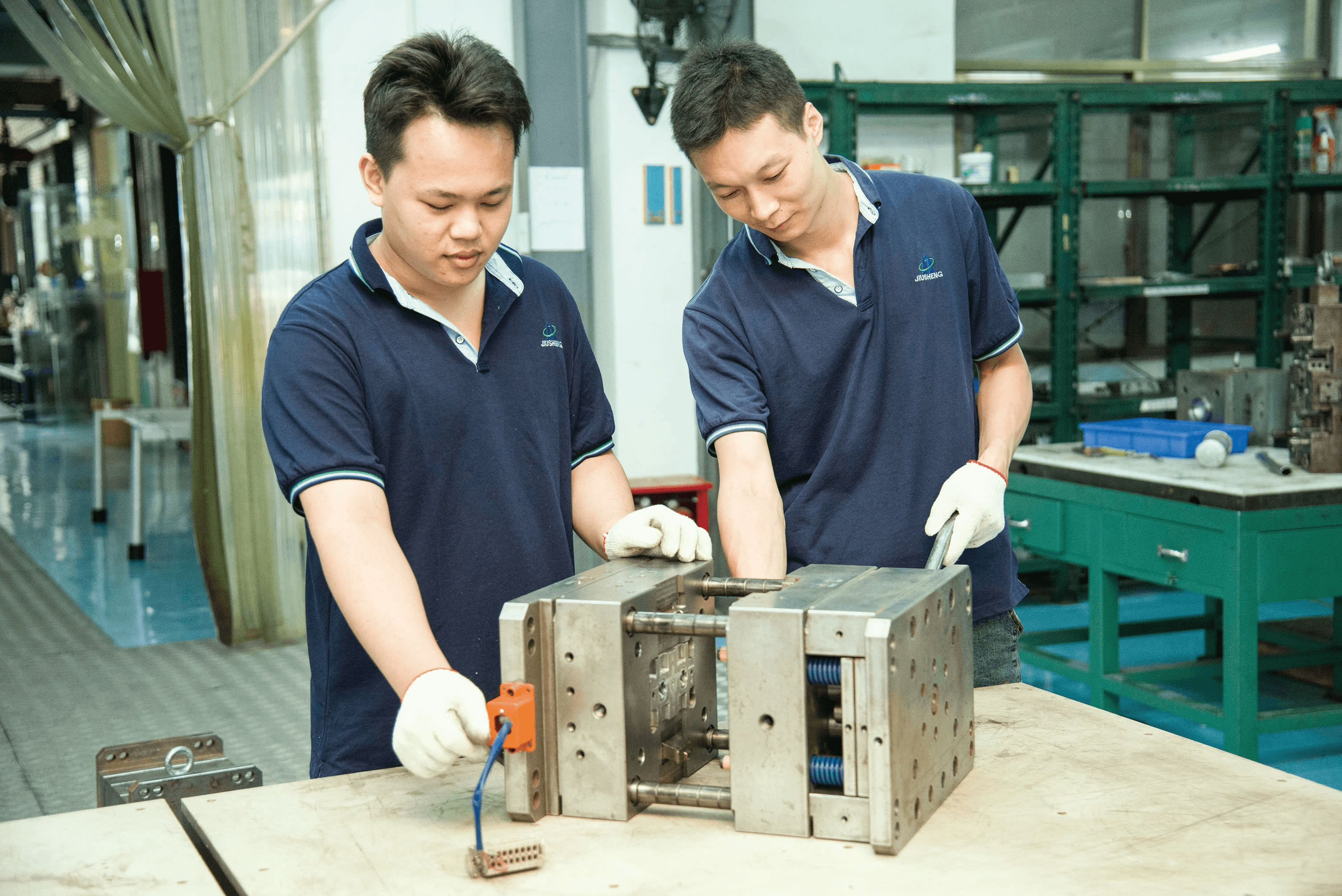

Labor and production overheads are another critical component contributing to the cost structure of plastic injection molding services. Skilled operators are necessary for running machinery effectively; their wages reflect their expertise and experience level within this specialized field. Additionally, maintenance staff must be considered since regular upkeep ensures optimal machine performance—failure to maintain equipment can lead to costly downtime.

Production overheads also include utilities like electricity needed to power machines during operation; these ongoing expenses should be factored into your overall budget as well. Understanding how labor rates fluctuate based on location or project complexity will help you better prepare financially when engaging with different service providers for your needs in mold plastic injection work. Ultimately, being aware of all these factors allows you to manage costs effectively while ensuring quality output from your chosen service provider.

Comparing Plastic Injection Molding Services

When it comes to plastic injection molding services, not all providers are created equal. Evaluating different service providers means looking beyond just the cost of plastic injection molding; you need to consider their capabilities, experience, and reputation in the industry. A thorough comparison can help you find a partner that offers quality alongside competitive pricing.

Evaluating Different Service Providers

Start by assessing the range of services offered by each provider, as this can significantly impact your project’s success. Look for companies that specialize in various types of injection molding, including custom mold plastic injection and high-volume production runs. Additionally, check for certifications and client testimonials to gauge reliability and quality assurance practices, ensuring your investment in plastic injection moulding service is well-placed.

Next, consider the technological capabilities of each provider. Advanced machinery and up-to-date techniques can lead to better precision and efficiency in producing injection moldable plastics. The right equipment not only enhances product quality but also affects the overall cost of plastic injection molding; investing in a provider with modern tools may save you money down the line.

Insights on Baoyuan's Expertise

Baoyuan stands out as a leader in the realm of plastic injection molding services due to its extensive experience and commitment to innovation. With years of expertise under their belt, they have honed their skills in both design and production processes for various industries. Their proficiency ensures that clients receive high-quality products at competitive prices without compromising on service or support.

Moreover, Baoyuan’s dedication to using state-of-the-art technology allows them to produce intricate designs with unparalleled accuracy—essential when working with complex mold plastic injections. Their team is adept at optimizing production methods which ultimately lowers costs while maintaining exceptional quality standards across all projects involving injection moldable plastics. This fusion of skill and technology makes Baoyuan an excellent choice for businesses looking for reliable partners.

Benefits of Choosing Experienced Teams

Choosing an experienced team for your plastic injection molding needs can provide significant advantages that go beyond just cost considerations. An established service provider will have refined processes that enhance efficiency—this translates into faster turnaround times without sacrificing quality on your final products made from injection moldable plastics. When time is money, this aspect cannot be overlooked!

Additionally, seasoned professionals bring invaluable insights into material selection and design optimization which can further reduce the overall cost of plastic injection molding projects over time. They are familiar with common pitfalls and challenges associated with different types of mold designs which helps prevent costly mistakes during production runs. Ultimately, partnering with an experienced team ensures a smoother process from concept through completion.

The Importance of Quality Assurance

In the world of plastic injection molding, quality assurance is not just a buzzword; it’s a necessity. The cost of plastic injection molding can be significantly impacted by the quality of the products produced. Ensuring that every component meets stringent quality standards can help avoid costly reworks and production delays, ultimately safeguarding your investment in plastic injection molding services.

Quality Control in Injection Molding

Quality control in injection molding involves systematic checks at various stages of production to ensure that mold plastic injection processes yield consistent, high-quality results. This includes monitoring material properties, dimensional accuracy, and surface finish throughout the production cycle. By implementing rigorous quality control measures, manufacturers can minimize defects and enhance the reliability of their injection moldable plastics.

The Cost of Poor Quality Products

The cost of poor quality products in plastic injection molding can be staggering, leading to wasted materials, increased labor costs for rework, and potential damage to a company’s reputation. When defective components reach customers, it not only incurs additional costs but may also result in lost business opportunities and diminished trust in your brand. Therefore, investing in robust quality assurance processes is essential for maintaining profitability and customer satisfaction within the realm of plastic injection moulding service.

Baoyuan’s Approach to Quality Assurance

Baoyuan takes pride in its comprehensive approach to quality assurance within its plastic injection molding services. By utilizing advanced technology and experienced personnel during every phase—from initial design through final inspection—Baoyuan ensures that each piece produced meets or exceeds industry standards for performance and durability. This commitment to excellence not only enhances the longevity of their mold plastic injections but also helps clients realize significant savings over time by reducing rework costs associated with inferior products.

Long-Term Cost Considerations

When diving into the world of plastic injection molding, understanding the long-term cost implications is crucial for making wise financial decisions. While the initial costs can seem daunting, especially concerning tooling and setup, it's essential to consider ongoing expenses and potential savings over time. This section will explore maintenance, cost benefits, and how production volume impacts the overall cost of plastic injection molding.

Maintenance of Injection Molding Equipment

Regular maintenance of injection molding equipment is key to ensuring optimal performance and longevity. Neglecting this aspect can lead to increased downtime and higher repair costs, which can significantly impact the overall cost of plastic injection molding. Investing in a reliable plastic injection moulding service that prioritizes equipment upkeep can save both time and money in the long run.

Moreover, a well-maintained mold plastic injection setup not only improves efficiency but also enhances product quality. Quality issues stemming from poorly maintained machinery can lead to costly reworks or even scrapped batches of injection moldable plastics. Therefore, partnering with experienced providers who emphasize maintenance is a smart move for any business looking to keep their costs down.

Cost Benefits Over Time

While upfront expenses are often highlighted when discussing the cost of plastic injection molding, it's vital to recognize that these costs can yield significant benefits over time. Efficient production processes reduce waste and maximize output, leading to lower per-unit costs as production scales up. As companies ramp up their orders with a reliable plastic injection molding service, they often see enhanced profitability due to improved economies of scale.

Additionally, choosing high-quality materials upfront may incur higher initial costs but can result in longer-lasting products that require fewer replacements or repairs down the line. This means that while you might pay more initially for certain mold plastic injections or materials, you’ll likely save money in future operational costs—an investment worth considering!

The Impact of Production Volume on Costs

Production volume plays a pivotal role in determining the overall cost structure associated with injection molding projects. Generally speaking, higher volumes lead to lower per-unit costs; this phenomenon occurs because fixed costs—like tooling—are spread across a larger number of units produced. Thus, businesses aiming for mass production often find that their investment in quality plastic injection moulding services pays off handsomely as they scale up operations.

However, it’s important for companies to strike a balance between volume and demand; producing too much without adequate market demand could lead to excess inventory and wasted resources. Understanding your specific needs regarding production volume ensures that you're not only optimizing your budget but also maximizing efficiency within your operations when using mold plastic injections or other related services.

In summary, by considering maintenance practices and recognizing how production volume affects pricing dynamics within the realm of plastic injection molding services, businesses can make informed decisions that enhance both quality and profitability over time.

Conclusion

In the ever-evolving world of manufacturing, understanding the cost of plastic injection molding is crucial for making informed decisions. With a plethora of factors influencing injection molding prices, from material selection to production volume, it’s essential to analyze all aspects before diving in. By doing so, businesses can optimize their budget and ensure a successful project outcome.

Making Informed Decisions on Costs

When navigating the cost of plastic injection molding, clarity is key. Companies must evaluate initial tooling and design expenses alongside ongoing material costs to avoid unpleasant surprises down the line. Additionally, understanding how labor and production overheads fit into the equation can help businesses make smarter financial choices regarding their plastic injection moulding service needs.

Choosing the Right Plastic Injection Molding Service

Selecting the right plastic injection molding service can significantly impact both quality and cost efficiency. It's important to research various providers and assess their expertise in handling different types of mold plastic injection projects. A reliable partner not only offers competitive pricing but also brings invaluable experience that can streamline processes and enhance product quality.

Why Quality Matters in Manufacturing

In manufacturing, quality isn't just an added benefit; it's a necessity that directly affects costs and customer satisfaction. The cost of poor-quality products can far outweigh any savings achieved through cheaper services, leading to increased rework or product recalls. Therefore, investing in high-quality plastic injection molding services ensures durability and reliability for your products while safeguarding your bottom line.