Introduction

In today's fast-paced manufacturing industry, the impact of injection mold automation cannot be overstated. This innovative technology has revolutionized production processes, leading to increased efficiency, reduced costs, and improved product quality. As businesses seek to stay competitive in the market, implementing automation in production has become a strategic necessity.

The Impact of Injection Mold Automation

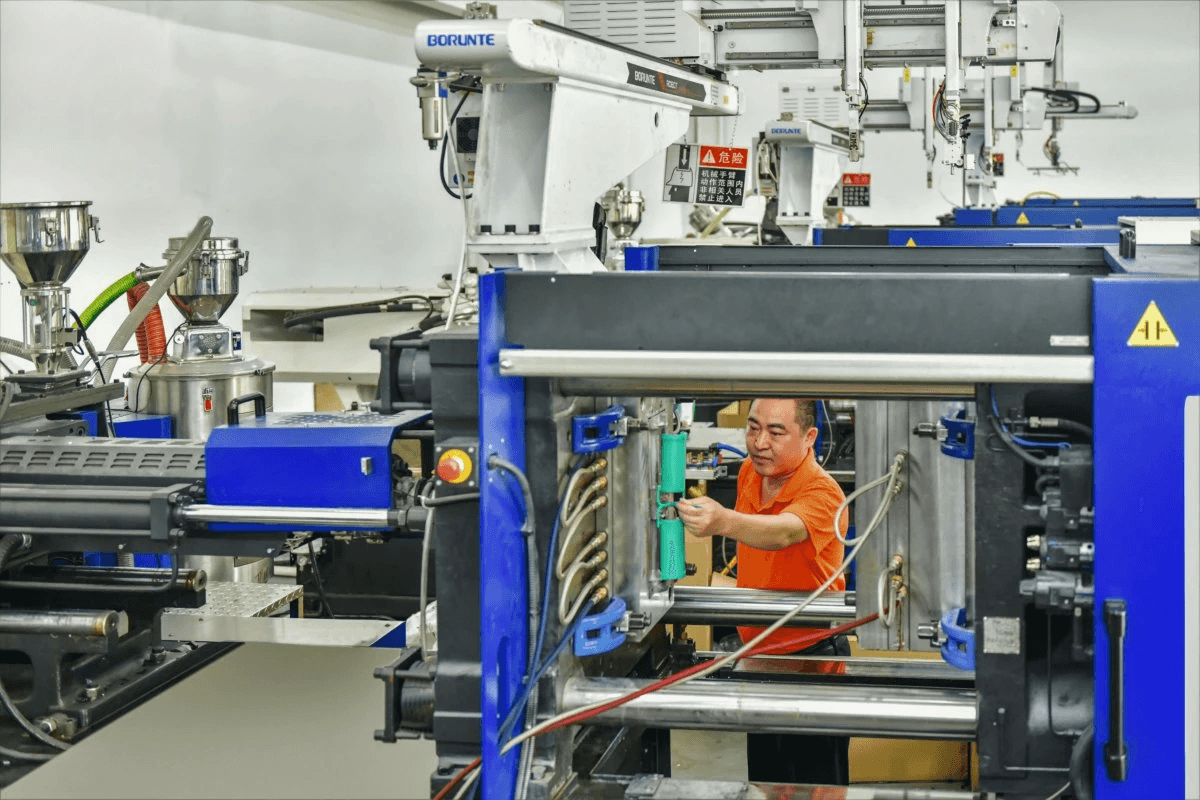

Injection molding is a highly efficient process that involves melting plastic and injecting it into a mold to create various products. With the integration of automation, this process becomes even more streamlined and cost-effective. Automation reduces the need for manual labor, resulting in faster production cycles and lower operational costs.

Advantages of Implementing Automation in Production

The advantages of implementing automation in production are numerous. It not only reduces labor costs but also enhances product quality and consistency. Additionally, automation minimizes human error and material waste while increasing overall production output.

Baoyuan: Revolutionizing Injection Mold Automation

Baoyuan is at the forefront of revolutionizing injection mold automation with its expertise in designing and implementing automated solutions for businesses across various industries. Their advanced software and technical prowess have set new standards for efficiency and productivity in injection molding operations.

Streamlining Production Processes with Automation

In today's competitive manufacturing landscape, companies are constantly seeking ways to reduce production time and costs. Injection molding, a widely used manufacturing process, can benefit greatly from automation. By implementing automated solutions, companies can significantly cut down on production time and costs associated with manual labor and human error.

Reducing Production Time and Costs

Injection molding is a complex process that requires precision and efficiency. With the use of automation, companies can streamline their production processes, leading to faster cycle times and reduced labor costs. By automating repetitive tasks such as material handling and quality control, manufacturers can achieve significant cost savings while increasing overall production output.

Improving Product Quality and Consistency

One of the key advantages of injection mold automation is the ability to improve product quality and consistency. Automated solutions ensure that each product meets the same high standard of quality, reducing the likelihood of defects or inconsistencies in the final output. This not only enhances customer satisfaction but also minimizes waste and rework, ultimately leading to cost savings for manufacturers.

Baoyuan's Expertise in Designing and Implementing Automated Solutions

Baoyuan has established itself as a leader in designing and implementing automated solutions for injection molding processes. With a team of experienced engineers and technical experts, Baoyuan specializes in developing custom automation systems tailored to meet the specific needs of each client. Their expertise in this area enables businesses to achieve greater efficiency, cost savings, and improved product quality through automation.

By leveraging Baoyuan's expertise in injection mold automation, businesses can effectively streamline their production processes while reducing costs and improving product quality. This strategic advantage allows companies to stay ahead in the market by maximizing efficiency through automated solutions.

Enhancing Efficiency through Robotic Automation

Robotic automation in injection molding is a game-changer, as it minimizes human error and material waste. By relying on precise robotic movements, the risk of errors is significantly reduced, leading to improved product quality and cost savings. Baoyuan's expertise in developing advanced software and technical solutions for robotic automation ensures seamless integration into production processes.

Minimizing Human Error and Material Waste

Robotic automation plays a crucial role in minimizing human error and material waste in injection molding. With precise robotic movements, the chances of errors are greatly reduced, leading to higher-quality products and reduced scrap rates. Baoyuan's cutting-edge robotic solutions are designed to optimize efficiency while minimizing waste, ensuring that every production cycle delivers superior results.

With the ability to operate 24/7, robotic automation also contributes to increasing overall production output in injection molding. By eliminating the need for human operators to take breaks or rest, robots can continuously work on molding tasks, leading to a significant boost in productivity. This increased output not only meets the demands of high-volume production but also allows manufacturers to fulfill orders more efficiently and effectively.

Increasing Overall Production Output

The implementation of robotic automation leads to a significant increase in overall production output. By streamlining processes and reducing cycle times, manufacturers can achieve higher throughput without compromising on quality. Baoyuan's expertise in designing automated solutions focuses on maximizing production output while maintaining the highest standards of product quality.

Robotic automation not only increases production output but also enhances efficiency and accuracy. By integrating advanced software and technical expertise, Baoyuan ensures that the automated solutions are tailored to the specific needs of manufacturers. This level of customization allows for seamless integration into existing processes, minimizing downtime and maximizing productivity.

Baoyuan's Advanced Software and Technical Expertise in Robotic Automation

Baoyuan stands out for its advanced software capabilities and technical expertise in robotic automation for injection molding. Their innovative approach leverages state-of-the-art technology to enhance efficiency and productivity across the production line. With a focus on continuous improvement, Baoyuan's automated solutions are tailored to meet the specific needs of each client, ensuring optimal performance and long-term success.

Baoyuan's commitment to staying ahead of the curve is evident in their continuous investment in research and development. By staying abreast of the latest technological advancements, Baoyuan ensures that their automated solutions are always at the forefront of innovation. This dedication to staying current allows them to offer their clients cutting-edge robotic automation options that deliver exceptional results.

Optimizing Workflow with Automated Mold Opening

Automated mold opening plays a crucial role in ensuring smooth and precise operations in injection molding. By automating this process, manufacturers can significantly reduce the risk of errors and ensure consistent quality in their products. Baoyuan's team of senior management and technical personnel are experts in designing and implementing automated solutions for mold opening, providing businesses with a competitive edge in their production processes.

Ensuring Smooth and Precise Mold Operations

Automated mold opening is essential for streamlining the production workflow in injection molding. It allows for quick and accurate mold operations, minimizing the risk of defects and ensuring that each product meets the highest quality standards. With Baoyuan's expertise in this area, businesses can optimize their production processes, reduce downtime, and ultimately improve their bottom line.

Automated mold opening not only improves efficiency but also enhances safety in the production environment. By minimizing the need for manual intervention, Baoyuan's expertise in mold opening automation reduces the risk of workplace accidents and injuries. This not only creates a smoother workflow but also contributes to a healthier and more secure work environment for employees.

Baoyuan's Senior Management and Technical Personnel's Expertise in Mold Opening Automation

Baoyuan's team of senior management and technical personnel are at the forefront of innovation when it comes to mold opening automation. Their wealth of experience and knowledge allows them to develop customized solutions that cater to the specific needs of each client. By leveraging their expertise, businesses can enhance their efficiency, reduce costs, and stay ahead of the competition in the injection molding industry.

Improving Product Quality with Injection Molding Automation

With injection molding automation, companies can consistently achieve high-quality plastic products that meet industry standards and customer expectations. This technology allows for precise and uniform production, resulting in durable and flawless end products that reflect the company's commitment to quality.

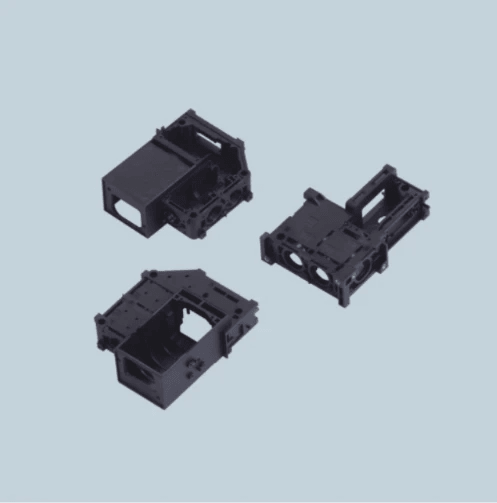

Consistently Achieving High-Quality Plastic Products

Injection molding automation ensures that each product meets stringent quality control measures, leading to a high level of consistency and reliability. This process reduces the likelihood of defects and errors, resulting in a superior end product that satisfies customer demands and enhances the company's reputation in the market.

Furthermore, injection molding automation allows for precise control over the production process, ensuring that each plastic product meets the highest standards of quality. This level of consistency and reliability is crucial in meeting customer demands and maintaining a competitive edge in the market. By consistently delivering superior end products, Baoyuan has established itself as a leader in the industry, trusted by customers for high-quality single-color and double-color products.

Baoyuan's Proficiency in Quality Assurance for Single-color and Double-color Products

Baoyuan specializes in providing quality plastic injection molding services for single-color and double-color products. Their expertise in quality assurance ensures that each product meets exacting standards, guaranteeing customer satisfaction and loyalty. With Baoyuan's proficiency, businesses can trust that their products will consistently meet or exceed industry benchmarks for excellence.

In addition to their expertise in quality assurance, Baoyuan leverages the power of automation to stay ahead of the competition. By incorporating advanced automated processes into their plastic injection molding services, Baoyuan is able to increase efficiency, reduce production costs, and minimize human error. This commitment to embracing cutting-edge technology not only sets them apart in the industry but also allows them to deliver high-quality products at a competitive price point.

Harnessing the Power of Automation for Competitive Edge

In today's fast-paced market, staying ahead requires enhanced production efficiency. Automation in injection molding is a game-changer, reducing production time and costs while improving product quality and consistency. With Baoyuan's expertise in designing and implementing automated solutions, businesses can gain a competitive edge by streamlining their production processes.

Staying Ahead in the Market with Enhanced Production Efficiency

With the rising demand for high-quality plastic products, businesses need to optimize their production processes to meet customer expectations while keeping costs in check. Injection molding automation offers a solution to this challenge by minimizing human error and material waste, ultimately increasing overall production output. This not only ensures a competitive edge but also positions businesses as leaders in the industry.

In addition to increasing production output, injection molding automation also improves product consistency and quality. By reducing the likelihood of human error, businesses can deliver high-quality plastic products that meet and exceed customer expectations. This not only enhances customer satisfaction but also solidifies a strong reputation in the market, attracting more clients and boosting sales.

Baoyuan's Commitment to Empowering Businesses with Injection Mold Automation Solutions

Baoyuan is dedicated to empowering businesses with cutting-edge injection mold automation solutions that drive efficiency and productivity. Their advanced software and technical expertise in robotic automation, mold opening automation, and quality assurance for single-color and double-color products make them the go-to partner for businesses looking to harness the power of automation for a competitive edge.

Baoyuan's commitment to empowering businesses with injection mold automation solutions extends beyond just providing cutting-edge technology. Their team of experts offers comprehensive training and support to ensure seamless integration and maximum utilization of their automation solutions. By prioritizing customer success, Baoyuan sets itself apart as a trusted partner for businesses seeking to optimize their production processes and stay ahead in the competitive market.

Conclusion

In conclusion, the future of production lies in embracing injection mold automation. With Baoyuan's expertise, businesses can leverage enhanced production efficiency to stay ahead in the competitive injection molding industry. The competitive advantage of automation is undeniable, offering cost-effective and high-quality solutions for businesses.

Embracing the Future of Production with Injection Mold Automation

Embracing injection mold automation is essential for businesses looking to streamline their production processes and stay competitive in the market. By implementing automated solutions, companies can significantly reduce production time and costs while ensuring consistent product quality and improved efficiency.

Leveraging Baoyuan's Expertise for Enhanced Production Efficiency

Baoyuan's expertise in designing and implementing automated solutions makes them a valuable partner for businesses seeking enhanced production efficiency. Their advanced software and technical knowledge in robotic automation and mold opening ensure smooth operations and optimized workflow for their clients.

The Competitive Advantage of Automation in Injection Molding Industry

The competitive advantage of automation in the injection molding industry cannot be overstated. Businesses can achieve high-quality plastic products consistently while minimizing human error and material waste, ultimately leading to increased overall production output.

Furthermore, automation allows for greater precision and consistency in the production process, leading to a higher level of product quality. This not only enhances the reputation of the company but also increases customer satisfaction and loyalty. With automation, businesses can also reduce lead times and respond more quickly to market demands, giving them a competitive edge over companies that rely solely on manual labor.