Introduction

Welcome to the world of two-shot molding, where innovation meets efficiency and quality. This article will explore its fascinating benefits, techniques, and applications. Get ready to discover Baoyuan's expertise in this cutting-edge manufacturing process.

Understanding Two-Shot Molding

Two-shot molding is a revolutionary injection molding process that creates complex molded parts with two different materials in a single operation. This innovative technique opens up a world of possibilities for designers and manufacturers, offering enhanced product functionality and aesthetics.

Exploring the Benefits of Two-Shot Molding

Two-shot molding offers a range of benefits that can revolutionize your product development process. Here's how:

- Cost-Effective: Two-shot molding combines multiple parts into a single molding cycle, reducing labor and eliminating the need for secondary assembly processes. This translates to significant cost savings.

- Improved Quality: Since everything is molded in one go, two-shot molding ensures superior part integrity and tighter tolerances than traditional methods. This leads to higher quality, more reliable products.

- Faster Cycle Times: By combining steps, two-shot molding significantly reduces overall production time. This allows you to ramp up production and meet market demands faster.

- Design Flexibility: Two-shot molding allows you to integrate different materials with unique properties into a single part. This opens doors for innovative designs with features like soft-touch grips or clear windows, all within one mold.

Two-shot molding offers a powerful combination of efficiency, quality, and design freedom, making it a valuable tool for advancing product development.

Baoyuan: Expertise in Two-Shot Molding

With years of experience and a deep understanding of two-shot molding, Baoyuan stands out as a leader in this field. Their expertise extends to advanced techniques, material selection, and precision manufacturing processes that deliver exceptional results for their clients.

What is Two-Shot Molding?

Two-shot molding is a revolutionary manufacturing technique that creates complex, multi-material parts in a single operation. This process involves injecting two different materials into a mold to produce a single component with two colors or materials. It is a cost-effective and efficient method for producing high-quality, durable parts with intricate designs.

The Basics of Two-Shot Molding

Two-shot molding offers several advantages over traditional molding methods:

- Simplified Production: The process injects two materials sequentially into one mold, eliminating the need for secondary assembly and streamlining production.

- Reduced Costs: Combining steps and two-shot molding saves time and lowers production costs.

- Enhanced Quality: Baoyuan's precision molding expertise ensures each part meets strict quality standards and specifications.

- Design Flexibility: This technique allows for creating complex geometries that would be difficult or impossible with other methods, opening doors for innovative product design.

Two-shot molding offers a faster, more cost-effective way to produce high-quality, unique parts with exceptional design freedom. With Baoyuan's expertise, you can leverage this technology to create products that stand out in the marketplace.

Advantages of Two-Shot Molding

Two-shot molding offers numerous advantages, including improved product durability, enhanced design flexibility, reduced production time, and cost savings. By combining different materials in one mold, manufacturers can create innovative products with unique color combinations and textures that were previously unattainable through traditional molding methods. Baoyuan's advanced two-shot techniques enable precise material distribution and exceptional surface finish.

Furthermore, Baoyuan's two-shot molding techniques also allow for the creation of complex geometries and intricate part designs that were previously challenging. This opens up new possibilities for product innovation and differentiation in the market. Additionally, combining materials with different properties in one mold enables manufacturers to produce parts with varying hardness, flexibility, or other characteristics, all in a single manufacturing process. This streamlines production and reduces the need for secondary operations or assembly, saving both time and costs.

Baoyuan's Advanced Two-Shot Techniques

Baoyuan has perfected advanced two-shot molding techniques to meet diverse customer needs and industry requirements. With state-of-the-art equipment and extensive experience in multi-material molding, Baoyuan can produce complex components with superior precision and consistency. By leveraging cutting-edge technology and innovative processes, Baoyuan delivers high-quality two-shot molded products that exceed customer expectations.

Furthermore, Baoyuan's expertise in two-shot molding extends to differentiating materials such as plexiglass and polycarbonate. Understanding each material's unique properties and characteristics allows Baoyuan to recommend the most suitable option for specific applications. This level of insight ensures that customers receive components that meet their requirements and optimize performance and durability. Baoyuan remains at the forefront of two-shot molding technology by staying abreast of material advancements and industry trends.

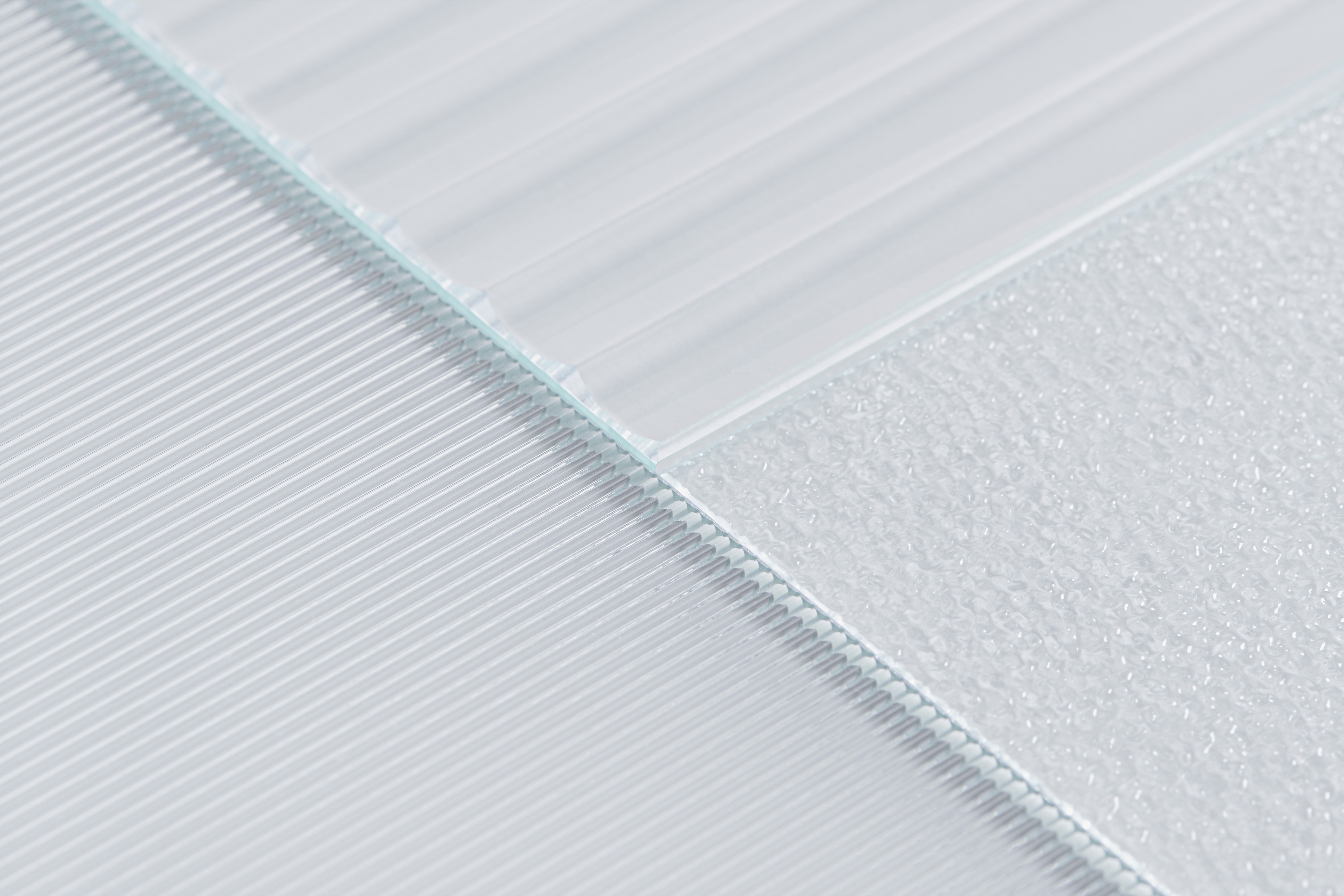

Differentiating Plexiglass vs Polycarbonate in Two-Shot Molding

Characteristics of Plexiglass and Polycarbonate

Selecting the right material for your two-shot molding project depends on the desired properties of the final product. Here's a breakdown of the key differences between plexiglass (acrylic) and polycarbonate:

- Clarity: Plexiglass offers superior optical clarity, making it ideal for applications where transparency is paramount.

- Impact Resistance: Polycarbonate boasts exceptional impact strength, which is ideal for parts that need to withstand physical stress.

- Weight: Plexiglass is significantly lighter than polycarbonate, a benefit for weight-sensitive applications.

- Temperature Tolerance: Polycarbonate can withstand higher temperatures than plexiglass, making it suitable for environments with heat exposure.

Both plexiglass and polycarbonate offer distinct advantages in two-shot molding. Understanding their unique properties allows you to select the best material to meet your specific project requirements.

Choosing the Right Material for Two-Shot Molding

Selecting the appropriate material for two-shot molding depends on the project's specific requirements. For instance, plexiglass may be the preferred choice if a product requires optical clarity and scratch resistance. Conversely, polycarbonate would be the better option if durability and impact resistance are paramount. Understanding these distinctions allows manufacturers to make informed decisions when choosing materials for their two-shot molding projects.

When selecting materials for two-shot molding, consider factors such as temperature resistance and chemical compatibility. Thermoplastic elastomers or silicone may be more suitable for applications requiring exposure to high temperatures due to their ability to withstand heat. On the other hand, if the product comes into contact with harsh chemicals, it is essential to choose a material resistant to corrosion and degradation. By carefully evaluating these additional considerations, manufacturers can ensure that the chosen materials will meet the project's specific demands.

Baoyuan's Insights on Material Selection

At Baoyuan, we understand that material selection is critical to achieving optimal results in two-shot molding. Our team of experts carefully evaluates each project's requirements to determine whether plexiglass or polycarbonate is better suited for the task at hand. By leveraging our extensive knowledge and experience in material science, we ensure that our clients receive superior-quality products that meet their specific needs.

As a leader in two-shot molding, Baoyuan recognizes the significance of polycarbonate lenses in this process. Polycarbonate is known for its exceptional impact resistance, making it an ideal choice for applications that require durability and strength. This material also offers excellent optical clarity, allowing for the production of high-quality lenses that meet stringent industry standards. We can deliver products that meet and exceed our client's expectations by utilizing polycarbonate in our two-shot molding process.

The Significance of Polycarbonate Lenses in Two-Shot Molding

Applications of Polycarbonate Lenses

Polycarbonate lenses are widely used in various industries, including automotive, medical, and consumer electronics. Their durability and impact resistance make them ideal for safety goggles, automotive headlights, and smartphone camera lenses. With their high optical clarity, polycarbonate lenses are also commonly used in eyewear and LED lighting applications.

Polycarbonate lenses are also increasingly used in virtual reality (VR) and augmented reality (AR) devices. Their lightweight nature and ability to be easily molded into complex shapes make them ideal for immersive visual experiences. Additionally, their impact resistance ensures that these lenses can withstand the wear and tear of regular use, making them a popular choice for VR and AR headset manufacturers.

Benefits of Using Polycarbonate Lenses in Two-Shot Molding

When it comes to two-shot molding, using polycarbonate lenses offers several advantages. These lenses can be seamlessly integrated with other materials to create complex designs and functionalities in a single manufacturing process. Additionally, their lightweight nature and resistance to scratches make them a preferred choice for products requiring clear visibility and long-lasting performance.

In addition, polycarbonate lenses are known for their impact resistance, making them an ideal choice for products that require durability and protection. This feature is especially beneficial for safety goggles, sports eyewear, and automotive headlight covers. Polycarbonate lenses' ability to withstand impact without shattering or cracking provides added peace of mind for both manufacturers and end-users.

Baoyuan's Expertise in Polycarbonate Lens Production

Baoyuan's advanced capabilities in polycarbonate lens production set them apart as industry leaders. Their state-of-the-art equipment and expertise allow precise molding of intricate lens designs with exceptional optical properties. By leveraging their extensive knowledge of material behavior and injection molding techniques, Baoyuan consistently delivers high-quality polycarbonate lenses for diverse applications.

Furthermore, Baoyuan is at the forefront of innovation in polycarbonate lens production, constantly exploring new two-shot techniques to enhance the performance and functionality of their lenses. Integrating multiple materials in a single molding process allows them to create lenses with unique features such as anti-scratch coatings, UV protection, and color tints. This innovative approach sets Baoyuan apart from its competitors and allows it to offer a diverse range of customized solutions to meet the specific needs of its clients.

Exploring Innovative Two-Shot Techniques

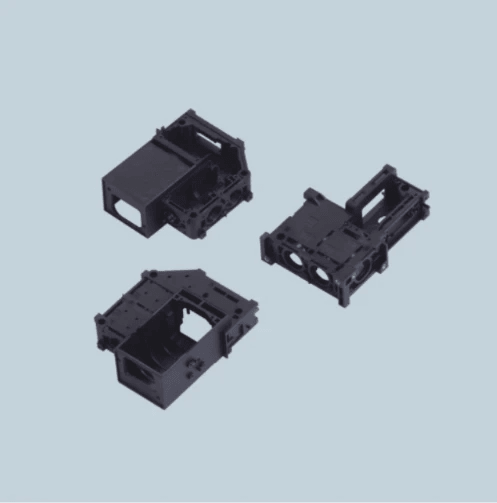

Examples of Two-Shot Molding Applications

When it comes to two-shot molding, the possibilities are endless. From creating intricate designs with multiple colors to producing complex parts with varying materials, two-shot molding offers a wide range of applications. For instance, it can manufacture automotive interior components, electronic device casings, and even medical equipment with precision and efficiency.

Two-shot molding can produce consumer goods such as household appliances and sporting equipment. By incorporating different materials and colors into the design, manufacturers can create visually appealing but also durable and functional products. This versatility allows the creation of innovative and eye-catching products that stand out in the market, giving companies a competitive edge in their respective industries.

Creative Designs with Two-Shot Molding

Two-shot molding allows for creating unique and eye-catching designs that would be difficult to achieve through traditional manufacturing methods. By combining different materials and colors in a single process, designers can unleash their creativity and bring innovative products to life. This opens up opportunities for creating products with enhanced aesthetics and functionality that stand out in the market.

Baoyuan's Cutting-Edge Two-Shot Molding Solutions

At Baoyuan, we pride ourselves on our cutting-edge two-shot molding solutions that push the boundaries of what is possible. With our state-of-the-art technology and expertise, we can deliver high-quality, custom two-shot molded parts that meet the specific needs of our clients. Our commitment to innovation drives us to continuously explore new techniques and materials to stay ahead in the industry.

Stay tuned for more insights into how Baoyuan is revolutionizing the world of two-shot molding!

Embrace Innovation: Baoyuan's Two-Shot Molding Excellence

Two-shot molding is a game-changer in the manufacturing industry, and Baoyuan's expertise in this field is unmatched. With its advanced techniques and cutting-edge solutions, Baoyuan is elevating quality and efficiency through two-shot molding. By embracing innovation, Baoyuan sets the bar high for excellence in this field.

Advancing with Baoyuan's Two-Shot Expertise

Baoyuan's mastery of two-shot molding goes beyond just the basics. Their deep understanding of the process allows them to push the boundaries of what is possible, creating intricate designs and complex parts with precision and finesse.

Baoyuan's expertise in two-shot molding is not limited to technical proficiency alone. Their innovative approach to the process allows them to create unique and eye-catching designs that stand out in the market. By combining different materials and colors in a single mold, they can achieve a level of complexity and sophistication that sets their products apart from the competition. This level of creativity and attention to detail sets Baoyuan apart in two-shot molding.

Elevating Quality and Efficiency with Two-Shot Molding

Using two-shot molding enhances product quality and streamlines production processes, reducing costs and time to market. Baoyuan's commitment to excellence ensures that every product manufactured through two-shot molding meets the highest standards. Furthermore, this innovative technology allows for the creation of complex and intricate designs previously difficult or impossible to achieve with traditional molding methods. This opens up a world of possibilities for product designers and engineers, enabling them to bring their creative visions to life in ways that were once considered unattainable.

Innovation is at the core of everything Baoyuan does. Their forward-thinking approach to two-shot molding has resulted in groundbreaking applications across various industries, setting new benchmarks for creativity and functionality.

By choosing Baoyuan as your partner in two-shot injection molding, you will gain access to their expertise and open doors to endless possibilities for creative designs and efficient production processes. With Baoyuan, the future of manufacturing is here.