Introduction

In the world of healthcare, precision and reliability are paramount, which is where medical injection molding comes into play. This advanced manufacturing process allows for the creation of intricate components that are essential in medical devices and equipment. Understanding what medical injection molding is can provide insights into its significance in producing high-quality medical parts that meet stringent industry standards.

Understanding Medical Injection Molding

So, what is medical injection molding? Simply put, it’s a process that involves injecting molten material into a mold to create various components used in medical devices. This technique enables manufacturers to produce complex shapes with high accuracy and repeatability, making it a preferred choice for many leading injection parts companies in the medical field.

Importance of Quality in Medical Parts

When it comes to healthcare, the importance of quality cannot be overstated. Medical parts must adhere to rigorous safety regulations and performance standards since they directly impact patient outcomes. Therefore, ensuring that each component produced through medical injection molding meets these quality benchmarks is crucial for both manufacturers and patients alike.

Overview of Leading Companies

The market for medical injection molding is vast, with numerous players vying for leadership positions. Companies such as Medtronic and Baxter International are among the largest injection molding companies in the world, specializing in creating reliable components for diverse applications. Their commitment to innovation and quality sets them apart as leaders within this competitive landscape.

The Basics of Medical Injection Molding

Diving into the world of medical injection molding reveals a complex yet fascinating process that forms the backbone of modern medical device manufacturing. This technique is pivotal for producing high-quality, precise components essential for healthcare applications. With an ever-growing market, understanding what medical injection molding entails is crucial for anyone involved in the industry.

What is Medical Injection Molding?

What is medical injection molding? It’s a specialized form of injection molding tailored specifically for creating parts used in medical devices and equipment. This process involves melting plastic pellets and injecting them into molds to form intricate shapes that meet stringent regulatory standards, ensuring safety and efficacy in healthcare applications. The precision required in this field means that only the top-tier injection parts companies can deliver the quality needed for such critical components.

Innovative Techniques in Injection Molding

In an era where technology reigns supreme, innovative techniques in injection molding are revolutionizing how we produce medical components. Companies are leveraging advancements like multi-material molding and 3D printing to create more complex designs with improved functionality while maintaining efficiency. These innovations not only enhance product performance but also address the growing demand within the market for medical injection molding by streamlining production processes.

Key Materials Used in Medical Production

The choice of materials is paramount when it comes to producing reliable medical devices, making it essential to understand what materials are commonly used in this field. High-grade plastics such as polycarbonate and polypropylene dominate due to their durability and biocompatibility—qualities that make them ideal for various applications within healthcare settings. As the landscape evolves, more companies are exploring advanced materials like thermoplastic elastomers (TPE) to meet specific requirements set forth by regulatory bodies, ensuring that they remain competitive among leading injection parts companies.

Market Overview of Medical Injection Molding

The market for medical injection molding is a dynamic and rapidly evolving sector that plays a crucial role in the healthcare industry. This segment focuses specifically on the production of medical devices, components, and parts through injection molding processes. As demand for innovative healthcare solutions rises, understanding what is the market for medical injection molding becomes essential for stakeholders looking to navigate this competitive landscape.

What is the Market for Medical Injection Molding?

Medical injection molding encompasses a variety of applications, from simple syringes to complex surgical instruments. The market is characterized by its need for precision and regulatory compliance due to the critical nature of medical devices. Companies specializing in this field, often referred to as injection parts companies medical, are tasked with ensuring that their products meet stringent quality standards while also innovating to keep pace with technological advancements.

With an increasing focus on patient safety and product reliability, the market has seen a surge in demand for high-quality injection molded parts. As healthcare providers seek more efficient and effective solutions, these companies are stepping up their game to deliver products that not only meet but exceed expectations. Thus, understanding what is medical injection molding helps clarify its significance in producing reliable healthcare solutions.

Growth Trends in the Medical Sector

The growth trends in the medical sector indicate a robust expansion fueled by technological advancements and an aging population requiring more healthcare services. As global health challenges evolve, there’s been an uptick in investment towards innovative medical devices produced via advanced techniques like injection molding. This trend bodes well for companies involved in producing high-quality components as they adapt to meet changing consumer demands.

Furthermore, increased awareness regarding preventive care has led to greater emphasis on diagnostic tools and wearable technologies—both heavily reliant on precision manufacturing techniques like those found in medical injection molding processes. Additionally, sustainability trends are pushing manufacturers toward eco-friendly materials while maintaining product integrity; thus reshaping how these companies operate moving forward.

As we explore what is the largest injection molding company in the world? It's clear that leading firms are leveraging these trends by expanding their capabilities and investing heavily into R&D initiatives aimed at improving efficiency across all stages of production—from design through delivery.

Major Players in the Medical Injection Parts Market

In any discussion about major players within this sector, several names stand out due not only to their size but also their commitment to innovation within medical manufacturing processes. Companies such as Medtronic and Johnson & Johnson have established themselves as leaders by consistently prioritizing quality control alongside cutting-edge technology integration into their operations—essentially redefining what it means to be an effective injection parts company medical today.

These industry giants collaborate with specialized firms dedicated solely towards creating superior plastic components tailored specifically for various applications across multiple disciplines within medicine including orthopedics or cardiology among others! Their combined efforts contribute significantly towards raising standards throughout all tiers associated with developing safe yet functional products designed ultimately around patient needs first—and foremost!

Additionally, smaller niche players have emerged who focus exclusively on specific aspects related directly back down into our earlier discussions surrounding what are the parts of an injection process? These organizations may not boast vast resources but excel at providing specialized solutions backed up by years’ worth expertise honed over time—proving invaluable when tackling unique challenges faced daily across diverse environments encountered throughout modern-day healthcare systems worldwide!

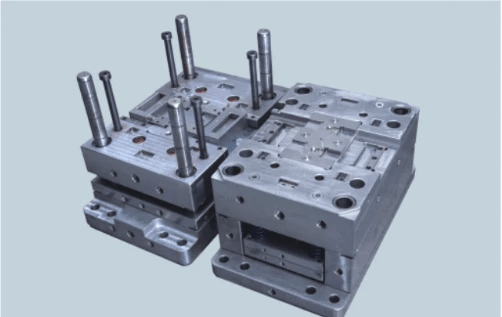

Essential Parts of Injection Molding

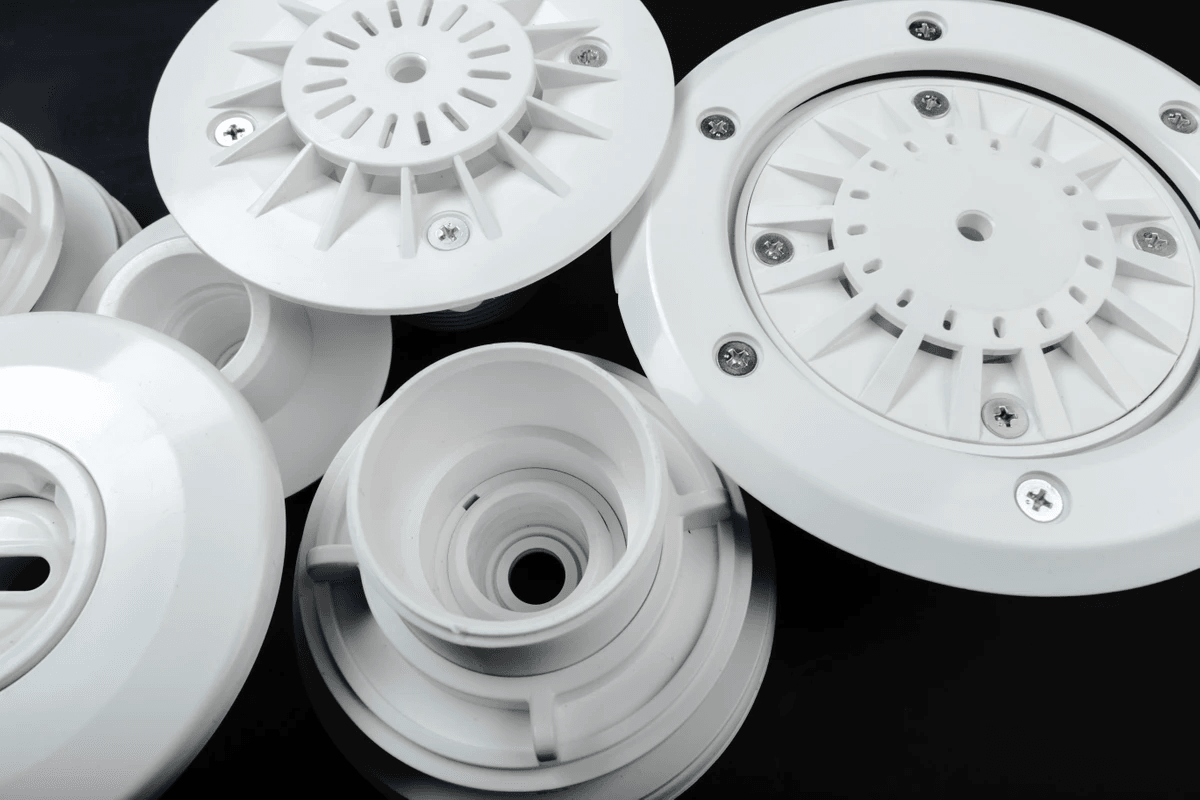

Medical injection molding is a complex process that relies on various components working in harmony to produce high-quality parts. Understanding these essential parts is crucial for anyone involved in the medical manufacturing sector, especially if you're considering which injection parts company medical would best suit your needs. This section will delve into what makes up an injection molding system and how precision plays a pivotal role in the production of medical devices.

What are the Parts of an Injection?

When we ask, What are the parts of an injection? we're referring to several key components that work together during the injection molding process. The main elements include the hopper, where raw materials are fed; the barrel, where materials are heated and melted; and the screw or plunger that injects molten plastic into molds. Each part plays a critical role in ensuring that medical devices meet stringent quality standards.

The design and functionality of these components can vary significantly depending on what is being produced, making it essential for companies to choose reliable injection parts company medical suppliers who understand these nuances. Moreover, understanding these components helps manufacturers optimize their processes for better efficiency and quality control. As technology evolves, so do these components, incorporating innovations that enhance performance and reduce waste.

Components in Medical Device Manufacturing

In medical device manufacturing, specific components stand out due to their importance in creating safe and effective products. These include specialized molds designed for complex shapes required by various devices such as syringes or surgical instruments. Additionally, temperature control systems are vital to maintain consistent conditions during production.

Choosing an experienced injection parts company medical can make all the difference when it comes to sourcing high-quality molds and materials tailored for this industry. The need for precision cannot be overstated; even minor deviations can lead to significant issues down the line—especially when dealing with life-saving devices where failure is not an option! Thus, understanding both standard and specialized components is crucial for success in this competitive market.

Role of Precision in Medical Injection Parts

An effective strategy involves investing in advanced technologies like computer numerical control (CNC) machines that enhance accuracy during production cycles while minimizing human error—a key factor many leading companies leverage today! By focusing on precision from start to finish, businesses can not only improve product quality but also build trust with clients who depend on them for critical healthcare solutions.

Quality Assurance in Medical Injection Parts

Ensuring the highest quality in medical injection parts is paramount, as these components can directly impact patient safety and treatment efficacy. An injection parts company medical must adhere to stringent standards and practices that not only meet regulatory requirements but also foster trust among healthcare providers and patients alike. This section delves into best practices for quality control, a real-world case study of Baoyuan's strategies, and the essential certifications that uphold industry compliance.

Quality Control Best Practices

Quality control best practices are crucial for any injection parts company medical aiming to deliver reliable products. It begins with rigorous testing of raw materials used in medical injection molding; ensuring they meet specified standards before production starts is non-negotiable. Moreover, implementing in-process inspections during manufacturing helps catch defects early, thus minimizing costly rework and ensuring that what comes out of the mold aligns with “What are the parts of an injection?” specifications.

Incorporating statistical process control (SPC) techniques can also aid companies in monitoring production processes effectively. By analyzing data trends, manufacturers can pinpoint variations that may lead to defects or inconsistencies in their products. Finally, fostering a culture of continuous improvement encourages teams to identify potential areas for enhancement regularly.

Case Study: Baoyuan's Quality Strategies

Baoyuan stands out as a leading example among injection parts companies in the medical field due to its commitment to quality assurance throughout its operations. The company's rigorous approach includes advanced testing methods such as real-time monitoring during the molding process and thorough validation protocols before product release. This dedication ensures their products not only comply with industry standards but also exceed customer expectations.

One notable aspect of Baoyuan's strategy is its investment in employee training programs focused on quality management principles tailored specifically for medical applications. By empowering staff with knowledge about what constitutes high-quality output, they create a workforce capable of identifying issues proactively rather than reactively addressing them later on. This proactive stance has positioned Baoyuan as a trusted name when considering What is the market for medical injection molding?

Furthermore, their collaboration with external auditors ensures that all processes are regularly reviewed against international benchmarks—an essential step for maintaining credibility within this highly regulated sector.

Certifications and Compliance in the Industry

Navigating certifications and compliance is critical for any injection parts company medical looking to thrive in today's market landscape. Regulatory bodies like the FDA (Food and Drug Administration) impose strict guidelines that manufacturers must follow to ensure product safety and effectiveness; therefore, obtaining relevant certifications such as ISO 13485 is vital for credibility within the industry.

Compliance does not merely serve as a checkmark on a list; it represents an ongoing commitment to quality throughout every stage of production—from design through distribution—while addressing questions like What is medical injection molding? effectively within organizational frameworks. Additionally, many companies pursue CE marking or other regional certifications depending on where they intend to market their products globally.

Staying abreast of changing regulations ensures that manufacturers remain competitive while safeguarding public health interests—a responsibility no injection parts company can afford to overlook if they hope to be recognized among What is the largest injection molding company in the world? competitors.

Innovations Shaping the Future

The landscape of medical injection molding is evolving rapidly, driven by technological advancements and a constant push for efficiency. Companies in this sector are embracing innovative practices that enhance production capabilities while maintaining the highest standards of quality. As we delve into these innovations, it becomes clear that they are not just trends; they are shaping the future of medical parts manufacturing.

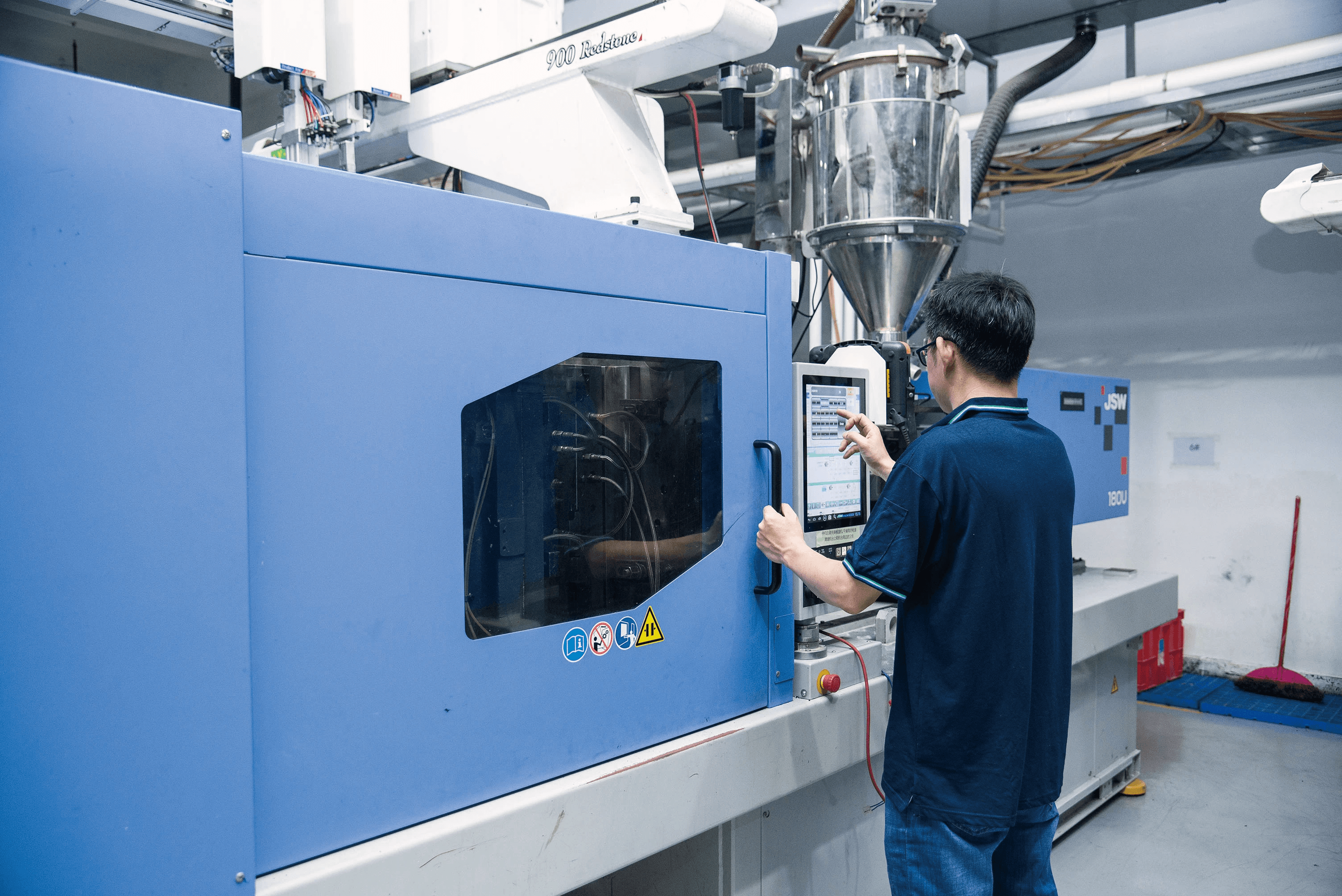

Latest Technologies in Injection Molding

What is medical injection molding? It’s a process that involves injecting molten material into a mold to create precise components essential for medical devices. Recent technological advancements have introduced new materials and processes, such as multi-material injection molding, which allows manufacturers to combine different materials in one part, enhancing functionality and performance. Additionally, advancements in 3D printing technologies are being integrated with traditional injection molding techniques to create prototypes faster and more efficiently.

In the quest for precision, companies are also adopting advanced simulation software that predicts how materials will behave during the injection process. This technology minimizes waste and optimizes designs before physical production begins. As these innovations continue to evolve, they position leading injection parts companies in the medical field at the forefront of efficient production methods.

The Role of Automation in Efficiency

Automation plays a crucial role in streamlining operations within an injection parts company medical sector. By integrating robotics into manufacturing processes, companies can achieve higher output rates while reducing human error—an essential factor when producing critical components for healthcare applications. Automated systems can handle repetitive tasks such as loading materials or inspecting finished products, freeing up skilled workers to focus on more complex responsibilities.

Moreover, automation enhances consistency across production runs—an important aspect when considering what is the market for medical injection molding? With increasing demand for high-quality products that meet stringent regulatory requirements, automation ensures that every part produced adheres to exact specifications without compromise. This efficiency not only boosts productivity but also reduces lead times significantly.

Future Trends in Medical Injection Parts Production

Looking ahead, several trends are set to revolutionize the landscape of medical injection parts production further. One significant trend is sustainable manufacturing practices; an increasing number of companies are exploring biodegradable materials and eco-friendly processes to minimize their environmental impact while meeting consumer demands for sustainability. This shift aligns with global efforts toward greener manufacturing solutions.

Another emerging trend involves personalized medicine—tailoring components specifically designed for individual patient needs requires flexibility and innovation from manufacturers. As technologies advance and patient-centric approaches gain traction within healthcare systems worldwide, what is the largest injection molding company in the world? It will likely be one that adapts quickly to these changes while providing customized solutions without sacrificing quality or efficiency.

In summary, innovations shaping the future of medical injection molding include cutting-edge technologies like multi-material processes and automation strategies designed to enhance efficiency while ensuring compliance with industry standards.

Conclusion

In summarizing the complexities and nuances of medical injection molding, it’s clear that this process is fundamental to the production of high-quality medical devices. A thorough understanding of what is medical injection molding? reveals its critical role in ensuring safety and reliability in healthcare applications. As we navigate through the market for medical injection molding, one can appreciate how innovation and precision come together to meet the demanding standards of the industry.

Key Takeaways from Medical Injection Molding

The key takeaways from our exploration into medical injection molding highlight its significance in producing essential components for healthcare. Understanding what are the parts of an injection helps stakeholders recognize how each element contributes to overall efficiency and effectiveness in manufacturing processes. Moreover, keeping abreast of the latest trends allows companies to stay competitive in a market where quality is non-negotiable.

The Significance of Choosing Reliable Suppliers

Choosing reliable suppliers is crucial for any injection parts company medical seeking to uphold quality standards. The largest injection molding company in the world often sets benchmarks that smaller firms strive to meet, emphasizing the importance of partnerships with reputable manufacturers. By aligning with trusted suppliers, businesses can ensure compliance with industry regulations while also benefiting from innovative practices that enhance production capabilities.

Embracing Innovation in Medical Production

Embracing innovation in medical production isn’t just about keeping up; it’s about leading the charge towards a more efficient future. With advancements such as automation and new materials reshaping what is possible within what is the market for medical injection molding? companies must adapt or risk falling behind competitors who are already leveraging these technologies effectively. Ultimately, fostering a culture of innovation will enable businesses to not only survive but thrive in an ever-evolving landscape.