Introduction

The automotive industry has seen a remarkable shift towards plastic injection molding, revolutionizing the way car parts are manufactured and assembled. This innovative method has not only enhanced the design and production of car components but has also significantly impacted the efficiency and sustainability of automotive manufacturing processes.

Introduction to Plastic Injection Molding in Automotive Industry

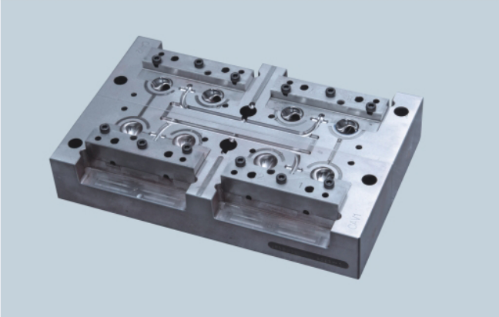

Plastic injection molding in the automotive industry involves the process of creating intricate and durable car parts by injecting molten plastic into a mold. This method has become increasingly popular due to its ability to produce complex shapes and designs with precision, making it an ideal solution for manufacturing various components within vehicles.

The Growing Importance of Injection Moulding in Automotive Industry

The growing importance of injection molding in the automotive industry is evident in its widespread adoption by leading car manufacturers. With its ability to produce lightweight yet strong parts, injection molding has played a crucial role in improving fuel efficiency and overall vehicle performance.

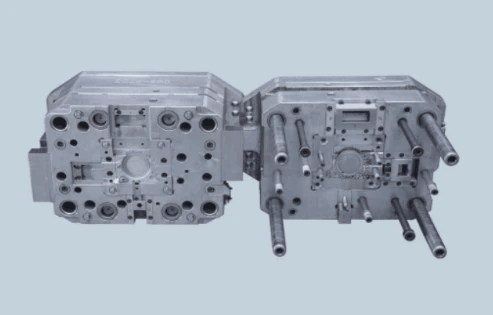

Baoyuan: Leading the Way in Automotive Plastic Molding

Baoyuan has emerged as a frontrunner in automotive plastic molding, leveraging expertise and cutting-edge technology to deliver high-quality, custom-designed car parts for leading automotive brands. Their commitment to innovation and excellence has positioned them as a key player in shaping the future of injection molding within the automotive industry.

Advantages of Plastic Injection Molding in Automotive Industry

Plastic injection molding offers numerous advantages for the automotive industry, including lightweight materials that contribute to improved fuel efficiency. By utilizing injection molding, car manufacturers can produce parts that are significantly lighter than traditional metal components, ultimately reducing the overall weight of vehicles and enhancing their performance on the road.

Lightweight and Fuel Efficiency

The use of plastic injection molding in automotive manufacturing has revolutionized the industry by providing lightweight solutions that contribute to improved fuel efficiency. This process allows for the creation of intricate and complex parts with minimal material usage, resulting in lighter vehicles that consume less fuel and emit fewer greenhouse gases. As a result, car manufacturers are increasingly turning to injection molding to meet stringent environmental regulations and consumer demand for eco-friendly automobiles.

Additionally, plastic injection molding allows for greater design flexibility, enabling car manufacturers to create parts that were previously impossible with traditional manufacturing methods. This versatility opens up new possibilities for innovative and aerodynamic vehicle designs, further contributing to improved fuel efficiency. With the ability to produce complex parts with precision and consistency, injection molding technology is driving the automotive industry towards a future of sleek, lightweight, and environmentally friendly vehicles.

Design Flexibility and Complex Parts

One of the key advantages of plastic injection molding is its ability to accommodate complex designs and intricate parts that would be difficult or impossible to achieve using traditional manufacturing methods. Automotive designers can leverage this flexibility to create innovative components that enhance vehicle performance, safety, and aesthetics. With Baoyuan's expertise in injection molding technology, car manufacturers can push the boundaries of design while ensuring high-quality production standards.

Baoyuan's Expertise in Designing and Molding Car Parts

Baoyuan has established itself as a leader in designing and molding car parts through plastic injection molding processes. With a deep understanding of automotive industry requirements, Baoyuan specializes in producing high-precision components that meet strict performance standards while offering design flexibility and cost-effective solutions. By leveraging advanced technologies and engineering expertise, Baoyuan continues to drive innovation in automotive plastic molding, providing car manufacturers with reliable solutions for their production needs.

In addition to its expertise in designing and molding car parts, Baoyuan also prides itself on its commitment to cost-effectiveness in the automotive industry. By optimizing the plastic injection molding processes, Baoyuan is able to minimize material waste and reduce production time, ultimately leading to lower manufacturing costs for car manufacturers. This focus on cost-effectiveness not only benefits Baoyuan's clients but also contributes to a more sustainable and efficient automotive supply chain.

Cost-Effectiveness of Injection Molding in Automotive Industry

Reduced Labor and Material Costs

Plastic injection molding in the automotive industry offers reduced labor costs as it requires minimal human intervention, leading to efficient production processes. With Baoyuan's expertise in injection molding, automotive companies can also benefit from reduced material costs through precise and optimized material usage.

Furthermore, with Baoyuan's advanced technology and expertise in injection molding, automotive companies can also benefit from faster production cycles. The precise and optimized material usage not only reduces material costs but also contributes to the overall efficiency of the manufacturing process. This allows for quicker turnaround times and helps automotive companies meet their production deadlines more effectively.

Faster Production Cycles

The advantage of injection moulding in automotive industry lies in its ability to facilitate faster production cycles compared to traditional manufacturing methods. Baoyuan's advanced technology and streamlined processes enable swift turnaround times for the production of high-quality car parts, meeting the demands of the automotive industry.

Furthermore, Baoyuan's efficiency in injection molding also contributes to cost savings for automotive manufacturers. By minimizing material waste and optimizing production processes, Baoyuan is able to offer competitive pricing for high-quality car parts. This cost-effectiveness allows automotive companies to remain competitive in the market and invest in further research and development for innovative vehicle designs.

Baoyuan's Efficiency in Injection Molding

Baoyuan stands out among automotive plastic injection molding companies due to its exceptional efficiency in delivering cost-effective solutions. By leveraging cutting-edge machinery and a skilled workforce, Baoyuan ensures that the injection molding process is executed with maximum efficiency, resulting in high-quality products at competitive prices.

Baoyuan's commitment to efficiency extends beyond just the production process. The company also places a strong emphasis on streamlining its supply chain and optimizing logistics to ensure timely delivery of products. By minimizing lead times and reducing inventory costs, Baoyuan is able to provide added value to its customers by offering quick turnaround times and flexible production schedules.

Quality and Durability of Automotive Plastic Molding

High Strength and Impact Resistance

Plastic injection molding in the automotive industry offers high strength and impact resistance, making it ideal for producing durable car parts that can withstand the rigors of daily use. Baoyuan's expertise in injection molding ensures that car components are robust and reliable, providing a level of durability that is essential for automotive applications.

Enhanced Aesthetics

One of the advantages of plastic injection molding in automotive industry is the ability to create parts with enhanced aesthetics. The process allows for intricate designs, smooth finishes, and customized textures, resulting in visually appealing car components. Baoyuan's attention to detail ensures that each molded part meets strict aesthetic standards, enhancing the overall look and feel of vehicles.

Baoyuan's Focus on Quality Assurance for Automotive Products

Baoyuan is committed to maintaining high-quality standards in automotive plastic molding. Through rigorous quality assurance processes, including thorough inspections and testing, Baoyuan ensures that every molded car part meets industry specifications for performance and safety. This dedication to quality assurance sets Baoyuan apart as a trusted partner for automotive plastic injection molding companies.

Environmental Benefits of Injection Molding in Automotive Industry

Waste Reduction and Recyclability

Plastic injection molding in the automotive industry contributes to waste reduction by producing less scrap material compared to traditional manufacturing methods. Additionally, the recyclability of plastic parts allows for a more sustainable approach to vehicle production, minimizing environmental impact.

Plastic injection molding also allows for the use of sustainable materials, such as bioplastics and recycled plastics, further reducing the environmental impact of automotive production. These sustainable material options offer the same level of performance and durability as traditional plastics, while also decreasing the reliance on non-renewable resources. By incorporating these materials into the manufacturing process, automotive companies can demonstrate their commitment to sustainability and environmental responsibility.

Sustainable Material Options

One of the key advantages of injection molding in automotive industry is the availability of sustainable material options, such as bioplastics and recycled plastics. These materials not only reduce reliance on non-renewable resources but also help in lowering carbon emissions, making them an eco-friendly choice for car manufacturers.

In addition to reducing reliance on non-renewable resources and lowering carbon emissions, sustainable material options in injection molding also offer cost savings for car manufacturers. Bioplastics and recycled plastics are often more affordable than traditional materials, helping companies reduce production costs without sacrificing quality. This makes them a practical choice for automotive industry, aligning environmental responsibility with financial benefits.

Baoyuan's Commitment to Environmentally Friendly Practices

Baoyuan's dedication to environmentally friendly practices extends beyond their use of sustainable materials and efficient waste management systems. They also prioritize energy efficiency in their manufacturing processes, reducing their carbon footprint and overall environmental impact. Additionally, Baoyuan actively seeks out innovative technologies and techniques that further minimize the environmental consequences of plastic injection molding for automotive applications.

The Future of Injection Molding in Automotive Industry

Technological Innovations

As the automotive industry continues to evolve, so does the technology behind injection moulding automotive industry. Advancements in materials, machinery, and design software are paving the way for more efficient and sustainable production processes. These innovations are enabling manufacturers to create complex and lightweight car parts with enhanced durability and performance.

Baoyuan's Role in Advancing Automotive Plastic Injection Molding

Baoyuan has been at the forefront of driving innovation in automotive plastic injection molding. With state-of-the-art facilities and a dedicated team of experts, Baoyuan is constantly pushing the boundaries of what is possible in terms of design, production efficiency, and material sustainability. Their commitment to research and development ensures that they remain a key player in shaping the future of injection moulding car parts.

Collaboration with Automotive Plastic Injection Molding Companies

Collaboration is key to driving progress in the automotive plastic injection molding industry. By partnering with other leading companies, Baoyuan can share knowledge, resources, and best practices to collectively elevate the standards of quality and innovation within the industry. Through strategic alliances, these companies can work together to address common challenges and capitalize on emerging opportunities.

Conclusion

Embracing the Potential of Plastic Injection Molding in Automotive Industry

Plastic injection molding has revolutionized the automotive industry, offering lightweight, durable, and cost-effective solutions for car parts. As the demand for fuel-efficient vehicles grows, injection molding will continue to play a crucial role in meeting these requirements.

As the automotive industry continues to prioritize sustainability and environmental responsibility, plastic injection molding offers a solution that aligns with these goals. By utilizing recycled materials and optimizing the manufacturing process, injection molding can contribute to reducing the carbon footprint of vehicle production. This not only meets the demand for fuel-efficient vehicles but also positions plastic molding as a key player in driving the industry towards a more sustainable future.

Baoyuan: A Key Player in Automotive Plastic Molding

Baoyuan has established itself as a leader in automotive plastic molding, with expertise in designing and molding car parts that meet the highest standards of quality and durability. Their commitment to innovation and sustainability sets them apart as a key player in the industry.

Baoyuan's dedication to staying at the forefront of technological advancements in automotive plastic molding has positioned them as an industry leader. Their investment in state-of-the-art equipment and continuous research and development ensures that they can consistently deliver high-quality, precision-engineered car parts. With a focus on sustainability, Baoyuan is not only meeting current industry standards but also setting new benchmarks for environmentally friendly manufacturing processes.

Looking Ahead: The Impact of Injection Molding on Automotive Industry

As technological advancements continue to shape the automotive industry, injection molding will play an even more significant role in producing complex parts with precision and efficiency. Collaborations between automotive plastic injection molding companies like Baoyuan and car manufacturers will drive further innovation and growth. With the increasing demand for lightweight and durable materials in vehicle manufacturing, injection molding provides the perfect solution for producing intricate and high-quality components. This process allows for the creation of parts that are not only cost-effective but also meet the stringent safety and performance standards of modern automobiles.