Introduction

Welcome to the world of injection molding, where precision and quality are paramount. In this guide, we'll delve into the fascinating realm of flash injection molding, exploring its nuances and practical solutions for flawless results. Join us as we uncover Baoyuan's expertise in injection molding and their commitment to delivering top-notch products free from any imperfections.

Understanding Flash Injection Molding

Flash injection molding is a common occurrence in the manufacturing process, where excess material escapes from the mold cavity, resulting in unwanted protrusions on the final product. This phenomenon can significantly impact the overall quality of the molded parts, leading to potential defects and inconsistencies.

Baoyuan's Expertise in Injection Molding

With years of experience and a deep understanding of injection molding techniques, Baoyuan has established itself as a leader in producing high-quality molds with exceptional precision. Their expertise extends to addressing flash-related issues, ensuring that each product meets rigorous standards for perfection.

Practical Solutions for Flash in Injection Molding

At Baoyuan, practical solutions for minimizing flash are at the forefront of their approach to injection molding. Through innovative techniques and meticulous attention to detail, they have perfected their methods for achieving flawless results, setting a new standard for excellence in the industry.

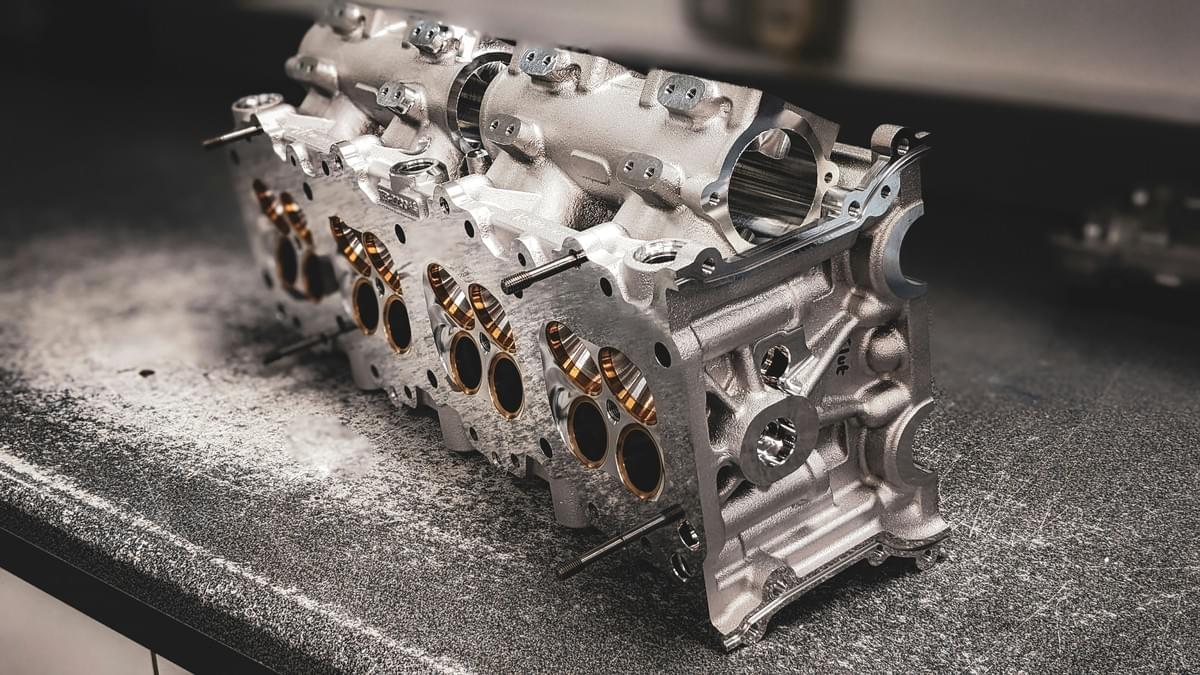

What is Flash in Injection Molding?

Flash injection molding occurs when excess material escapes from the mold cavity during the injection process, leading to thin fins or protrusions on the final product. This phenomenon can negatively impact the overall quality and appearance of the molded parts.

Explaining the Phenomenon of Flash

Flash in injection molding is caused by excessive pressure or temperature, which forces molten plastic to escape through small gaps in the mold. This results in unwanted excess material that needs to be removed post-production, adding extra time and cost to the manufacturing process.

Impact of Flash on Molding Quality

The presence of flash can compromise the dimensional accuracy and surface finish of molded parts, leading to potential functional issues or aesthetic flaws. It can also affect the overall integrity and strength of the final product, making it crucial to address this issue effectively.

Baoyuan's Approach to Minimizing Flash

Baoyuan tackles flash in injection molding by employing advanced mold design and precision tooling techniques that minimize gaps and ensure tight seals during the injection process. Their expert team also utilizes optimized processing parameters to control pressure and temperature, reducing the likelihood of flash occurrence.

Causes of Flash in Injection Molding

Flash injection molding is a common issue caused by various factors. Mold design and tooling issues play a significant role in the occurrence of flash. Poor mold design, improper venting, or worn-out tooling can lead to flash defects in the final product. Baoyuan's expertise in identifying and rectifying these issues ensures minimal flash during the injection molding process.

Mold Design and Tooling Issues

Improper mold design, such as inadequate venting or excessive tool wear, can result in flash formation during injection molding. Baoyuan's team of experts meticulously inspect and optimize mold designs to prevent flash defects. By addressing venting and tooling issues, they ensure that the molds are well-suited for producing high-quality products without flash.

Material and Process Factors

Material selection and processing parameters also contribute to the occurrence of flash in injection molding. Inappropriate material viscosity or temperature, as well as suboptimal processing conditions, can lead to excess material seeping out of the mold cavity, resulting in flash defects. Baoyuan's extensive knowledge of material properties and precise control over processing parameters minimizes these factors, preventing flash formation.

Baoyuan's Strategies for Preventing Flash

Baoyuan employs advanced techniques such as precise mold temperature control, optimized injection pressure, and accurate material flow control to prevent flash during injection molding. Their comprehensive approach addresses potential causes of flash at every stage of the manufacturing process, ensuring superior quality products with minimal defects.

By implementing these strategies for preventing flash in injection molding processes at Baoyuan Plastic Co., Ltd., you can achieve flawless products with exceptional quality while minimizing production setbacks due to defective parts.

Differentiating Between a Burr and Flash

When it comes to injection molding, it's crucial to understand the difference between a burr and flash. While a burr is an unwanted piece of material that forms on the edge of the part, flash is the excess material that leaks out of the mold during the molding process. Many people mistakenly use these terms interchangeably, but in reality, they require different approaches for removal.

Identifying and Addressing Common Misconceptions

One common misconception is that burrs and flash are essentially the same thing. However, burrs are typically easier to detect as they appear as small, thin projections along the edges of the molded part. On the other hand, flash can be more challenging to identify as it often blends in with the rest of the part and may require closer inspection for detection.

Baoyuan's Expert Insight on Quality Assurance

Baoyuan's extensive experience in injection molding has provided them with valuable insights into quality assurance when it comes to addressing flash defects. By utilizing advanced techniques and state-of-the-art equipment, Baoyuan ensures that their products are free from any imperfections caused by flash during the molding process.

Best Practices in Dealing with Flash Defects

Dealing with flash defects requires precision and expertise. Baoyuan follows best practices such as implementing meticulous quality control measures, utilizing specialized tooling modifications, and optimizing their injection molding processes to minimize or eliminate flash altogether.

Practical Solutions to Minimize Flash

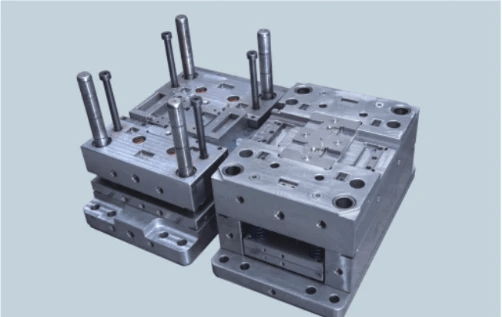

When it comes to minimizing flash in injection molding, tooling and mold design modifications play a crucial role. Baoyuan's team of experts meticulously analyze the mold design and make necessary adjustments to prevent flash formation. By optimizing the tooling and mold design, Baoyuan ensures that flash is minimized, resulting in high-quality injection molded products.

Tooling and Mold Design Modifications

Baoyuan's skilled engineers carefully examine the mold design to identify potential areas where flash can occur. They then make precise modifications to the tooling and mold design to eliminate any chances of flash formation during the injection molding process. By implementing these strategic changes, Baoyuan guarantees flawless products with minimal flash defects, setting them apart as leaders in the industry.

After identifying potential areas for flash formation, Baoyuan's engineers utilize advanced 3D modeling software to create precise modifications to the tooling and mold design. This allows them to visualize and analyze the changes before implementation, ensuring an optimal solution. By leveraging cutting-edge technology in their process, Baoyuan demonstrates their commitment to innovation and excellence in mold design modifications.

Process Optimization Techniques

In addition to tooling and mold design modifications, Baoyuan employs advanced process optimization techniques to minimize flash in injection molding. By fine-tuning the injection molding process parameters such as temperature, pressure, and cooling time, Baoyuan ensures that each product is manufactured with precision and accuracy, free from any unwanted flash defects.

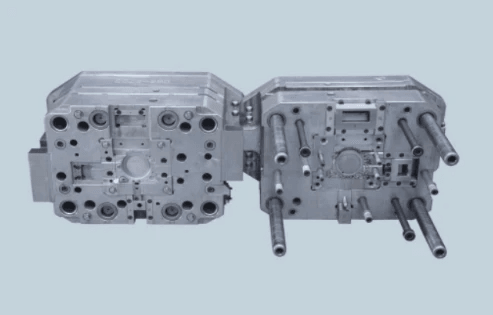

Baoyuan's Specialized Mold Opening and Injection Molding Techniques

Baoyuan's specialized mold opening and injection molding techniques are designed specifically to minimize flash formation. Their state-of-the-art equipment allows for precise control over the entire injection molding process, ensuring that each product is produced with exceptional quality and without any trace of flash defects. By utilizing advanced technology and meticulous attention to detail, Baoyuan sets the standard for flash-free products in the industry. This commitment to excellence not only enhances the aesthetic appeal of their products but also ensures optimal functionality and durability.

Quality Assurance for Flash-Free Products

At Baoyuan, we take pride in offering a wide range of single-color and double-color plastic products that are free from flash defects. Our state-of-the-art injection molding techniques ensure that each product meets the highest quality standards, providing our customers with durable and flawless finished goods.

Baoyuan's Single-Color and Double-Color Plastic Products

Our single-color and double-color plastic products are manufactured using advanced injection molding processes that eliminate the risk of flash defects. From simple components to complex parts, our products are designed to meet the specific needs of our clients while maintaining exceptional quality and precision.

Our commitment to quality extends beyond the manufacturing process, as we implement stringent quality control measures to ensure that each product meets our high standards. Through thorough inspection and testing, we guarantee that our single-color and double-color plastic products are free from any defects or imperfections. This dedication to excellence allows us to provide our clients with reliable and durable plastic components that consistently meet their expectations.

Implementing Stringent Quality Control Measures

Quality control is at the heart of our manufacturing process at Baoyuan. We implement stringent measures to inspect each product for any signs of flash defects, ensuring that only flawless items leave our facilities. Our commitment to quality control guarantees that our customers receive products that exceed their expectations.

As a testament to our dedication to producing high-quality molds, we have invested in state-of-the-art inspection equipment to ensure that every product meets our strict quality standards. Our team of experienced quality control specialists meticulously examines each mold, leaving no room for error or subpar workmanship. This level of attention to detail not only sets us apart from our competitors but also gives our customers the peace of mind that they are receiving top-notch products.

Baoyuan's Commitment to Producing High-Quality Molds

We understand the importance of producing high-quality molds to achieve flash-free injection molding. At Baoyuan, we invest in cutting-edge technology and employ skilled professionals who are dedicated to creating molds with precision and accuracy. Our commitment to excellence is evident in every mold we produce.

Our state-of-the-art facilities and advanced machinery allow us to produce molds that meet the highest industry standards. Our team of skilled professionals undergoes rigorous training to ensure that they are equipped with the latest techniques and knowledge in mold-making. This dedication to staying ahead of the curve in technology and expertise sets us apart in the industry, guaranteeing that every mold we produce is of the highest quality.

Conclusion

Baoyuan's Proven Expertise in Flash-Free Injection Molding

When it comes to flash injection molding, Baoyuan's expertise is unmatched. With years of experience and a deep understanding of the process, Baoyuan has perfected the art of producing flawless injection molded products, free from any flash defects. Their commitment to quality and innovation sets them apart as leaders in the industry.

Achieving Superior Molding Quality with Baoyuan

Partnering with Baoyuan means achieving superior molding quality for your products. By utilizing advanced techniques and state-of-the-art equipment, Baoyuan ensures that every product meets the highest standards of quality and precision. With Baoyuan, you can trust that your injection molded products will be free from any flash defects, guaranteeing customer satisfaction. Furthermore, Baoyuan's commitment to continuous improvement means that they are always striving to innovate and optimize their processes, ensuring that your products are manufactured with the latest advancements in the industry.

Partnering with Baoyuan for Flawless Injection Molding

For flawless injection molding without any flash defects, partnering with Baoyuan is the key to success. Their dedicated team of experts works tirelessly to deliver top-notch results, providing practical solutions and innovative strategies to minimize flash in injection molding. With Baoyuan as your partner, you can rest assured that your products will be of the highest quality.

In addition to their expertise in minimizing flash defects, Baoyuan also offers a wide range of materials and finishes to meet your specific injection molding needs. Whether you require high-temperature resistant materials or custom color matching, Baoyuan has the capabilities to deliver exceptional results. By partnering with Baoyuan, you gain access to their extensive resources and industry knowledge, ensuring that your injection molding projects are completed with precision and excellence.