Introduction

When it comes to the manufacturing of car parts, automotive injection molding plays a crucial role in the production process. This innovative technology involves the use of plastic injection molding to create various components for vehicles, offering a cost-effective and efficient solution for the automotive industry. The benefits of automotive injection molding are numerous, including enhanced design flexibility, reduced production time, and improved durability of car parts.

Understanding Automotive Injection Molding

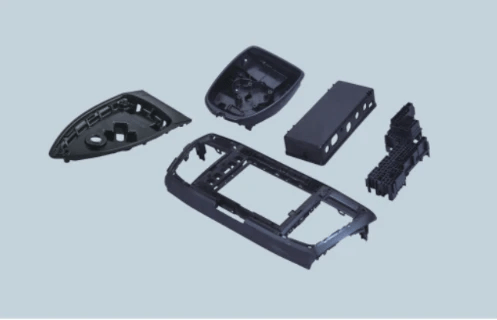

Automotive injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity to create car parts such as bumpers, dashboards, and interior trims. This process allows for intricate designs and complex shapes to be produced with high precision, making it an ideal solution for the automotive industry's diverse needs.

Role of Plastic Injection Molding in Automotive Industry

Plastic injection molding has revolutionized the way car parts are manufactured in the automotive industry. Its ability to produce large volumes of components at a rapid pace has significantly contributed to streamlining production processes and meeting market demands efficiently.

Benefits of Automotive Injection Molding

The benefits of automotive injection molding are far-reaching. Not only does it offer cost-effective solutions for mass production, but it also ensures consistent quality and durability in car parts. Additionally, this technology allows for lightweight yet sturdy components to be created, contributing to improved fuel efficiency and overall vehicle performance.

Automotive Injection Molding Explained

Automotive injection molding is a manufacturing process that involves injecting molten plastic into a mold to create car parts. This process is highly efficient and allows for the production of complex shapes and designs, making it ideal for the automotive industry.

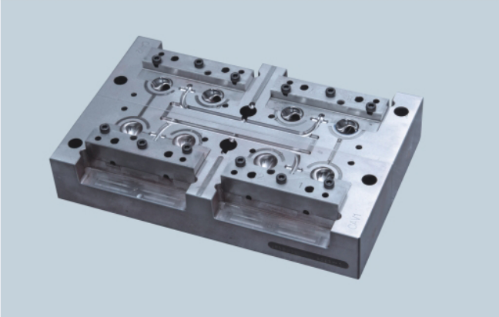

Process of Automotive Injection Molding

The process of automotive injection molding begins with the melting of plastic pellets in an injection molding machine. The molten plastic is then injected into a mold, where it cools and solidifies into the desired shape. Once the part is formed, it is ejected from the mold and can undergo additional finishing processes before being used in cars.

Plastic Injection Molding Technology

Plastic injection molding technology has advanced significantly in recent years, allowing for greater precision and efficiency in car part production. With innovations such as computer-aided design (CAD) and computer-aided manufacturing (CAM), manufacturers can create intricate molds and produce high-quality car parts with minimal waste.

Applications in Automotive Industry

The applications of plastic injection molding in the automotive industry are vast, ranging from interior components like dashboards and door panels to exterior parts such as bumpers and fenders. This technology enables car manufacturers to produce lightweight yet durable parts that contribute to fuel efficiency and overall vehicle performance.

Now let's delve into the key players in automotive injection molding to understand their impact on car part production.

Key Players in Automotive Injection Molding

When it comes to automotive injection molding, Baoyuan stands out as a leader in the industry. With their expertise in injection molding, Baoyuan has been instrumental in revolutionizing car parts production. Their innovative approach and cutting-edge technology have set the bar high for other automotive injection molding companies.

Baoyuan: Expertise in Injection Molding

Baoyuan's expertise in injection molding is unmatched, making them a go-to choice for automotive manufacturers. Their state-of-the-art facilities and skilled workforce ensure that they deliver top-notch quality car parts molds. With a focus on precision and efficiency, Baoyuan continues to lead the way in the injection molding industry.

In addition to their expertise in injection molding, Baoyuan also prides itself on its commitment to sustainability. By implementing eco-friendly practices and using recyclable materials, they are able to reduce their environmental impact and contribute to a greener automotive industry. This dedication to sustainability sets them apart from other injection molding companies and appeals to environmentally conscious manufacturers looking for reliable and responsible partners.

Leading Automotive Injection Molding Companies

In addition to Baoyuan, other leading automotive injection molding companies such as Denso Corporation and Magna International are also making significant contributions to the industry. Denso Corporation is known for its advanced technology and expertise in producing high-quality automotive components through injection molding. On the other hand, Magna International has established itself as a key player in the market by continuously investing in research and development to enhance its molding capabilities. These companies are at the forefront of driving advancements in automotive injection molding technology, setting new standards for quality and efficiency.

Impact of Injection Molding on Car Parts Production

The impact of injection molding on car parts production cannot be overstated. It has revolutionized the way car parts are manufactured, allowing for greater precision, efficiency, and cost-effectiveness. With advancements in plastic injection molding technology, car manufacturers can now produce high-quality components at a faster pace than ever before.

The use of injection molding in car parts production has also led to a significant reduction in material waste, as the process allows for the precise control of material usage. This not only benefits the environment by minimizing the amount of plastic waste generated but also contributes to cost savings for car manufacturers. Additionally, injection molding enables the production of complex and intricate designs that were previously unattainable through traditional manufacturing methods, allowing for greater design flexibility and innovation in car part production.

Advantages of Automotive Injection Molding

Automotive injection molding offers numerous advantages, including the efficiency of the injection molding machine. With fast and precise production capabilities, this technology ensures quick turnaround times for car parts manufacturing. This efficiency translates to cost savings and increased productivity for automotive companies.

Efficiency of Injection Molding Machine

The injection molding machine's ability to produce car parts with high precision and at a rapid pace is a game-changer for the automotive industry. The streamlined process reduces production time, leading to lower labor costs and increased output. This efficiency allows automotive manufacturers to meet market demands while maintaining high-quality standards.

Furthermore, the efficiency of injection molding machines also contributes to a reduction in material waste. The precise and rapid production process ensures that each car part is manufactured with minimal material usage, resulting in cost savings for automotive manufacturers. This environmentally friendly approach aligns with the industry's growing focus on sustainability and responsible manufacturing practices. As a result, injection molding technology not only benefits the automotive industry from a productivity standpoint but also from an ecological perspective.

Quality Assurance in Injection Molding

One of the key benefits of automotive injection molding is the consistent quality assurance it provides for car parts production. The technology ensures that each part is manufactured with precision and uniformity, reducing the risk of defects or inconsistencies in the final products. This reliability is crucial for ensuring vehicle safety and performance.

Environmental Benefits of Plastic Injection Molding

In addition to its efficiency and quality assurance, plastic injection molding offers environmental benefits that are increasingly important in today's automotive industry. The process minimizes material waste by using only the necessary amount of plastic, reducing environmental impact. Furthermore, many automotive companies are turning to sustainable materials for injection molding, further enhancing their eco-friendly practices.

Additionally, plastic injection molding in the automotive industry reduces energy consumption compared to other manufacturing processes, contributing to a lower carbon footprint. The use of sustainable materials not only reduces environmental impact but also promotes the development and use of renewable resources. This shift towards eco-friendly practices in plastic injection molding aligns with the growing consumer demand for environmentally responsible products, giving automotive companies a competitive edge in the market.

Innovation in Automotive Injection Molding

Advancements in Mold Design have revolutionized automotive injection molding, allowing for more complex and intricate car parts to be produced with precision. The use of advanced materials and techniques has led to improved durability and performance of molded car components, meeting the high standards of the automotive industry.

Integration of New Technologies has played a crucial role in enhancing the efficiency and effectiveness of plastic injection molding in the automotive sector. Automation, robotics, and digitalization have streamlined the manufacturing process, resulting in faster production cycles and reduced costs for car part manufacturers.

Future of Injection Molding Industry is bright with continuous innovation and development on the horizon. As demand for lightweight, durable, and sustainable materials grows in the automotive industry, injection molding is poised to play an even more significant role in shaping the future of car parts production.

Remember to include these keywords:automotive injection moldinq, Plastic Injection Molding Applications in Automotive Industry, Benefits Of Plastic Injection Molding In Automotive, Plastic Injection Molding Technology, Automotive injection molding companies, Injection molding industry, Injection molding machine, Car parts Mold

Conclusion

Automotive injection molding is set to revolutionize the car parts production industry, with companies like Baoyuan leading the charge. The future of automotive injection molding looks promising, as advancements in mold design and integration of new technologies continue to enhance the efficiency and quality of car parts production.

The Future of Automotive Injection Molding

The future of automotive injection molding is bright, with continuous innovations and advancements in technology. As the demand for high-quality, efficient car parts production grows, automotive injection molding will play a crucial role in shaping the future of the automotive industry.

As the demand for high-quality, efficient car parts production grows, automotive injection molding will play a crucial role in shaping the future of the automotive industry. With advancements in technology, automotive injection molding processes are becoming more precise and efficient, allowing for the production of complex and lightweight car parts. This not only improves the overall performance and fuel efficiency of vehicles but also contributes to reducing their environmental impact.

Enhancing Car Parts Production with Baoyuan

Baoyuan's expertise in injection molding has significantly enhanced car parts production in the automotive industry. With their cutting-edge technology and commitment to quality assurance, Baoyuan continues to be a key player in driving innovation and efficiency in automotive injection molding. Their advanced techniques have allowed for the production of complex and intricate car parts with precision and consistency, meeting the high standards of modern vehicles. Additionally, Baoyuan's focus on sustainability and environmentally friendly practices ensures that their injection molding processes are not only efficient but also eco-conscious, aligning with the automotive industry's push towards greener manufacturing solutions.

Maximizing Benefits of Injection Molding Technology

The benefits of plastic injection molding in automotive are undeniable, from its environmental advantages to its efficiency and quality assurance. As more automotive injection molding companies embrace this technology, the industry will continue to maximize its benefits for sustainable and high-quality car parts production.

As more automotive injection molding companies embrace this technology, the industry will continue to maximize its benefits for sustainable and high-quality car parts production. One of the key advantages of injection molding in automotive is its ability to produce complex and intricate designs with high precision, allowing for the creation of innovative and advanced car parts. This technology also offers cost-effective solutions for mass production, reducing manufacturing expenses and ultimately leading to more affordable vehicles for consumers. Additionally, the use of recyclable materials in plastic injection molding contributes to a more environmentally friendly manufacturing process, aligning with the automotive industry's push towards sustainability. With these factors in mind, it's clear that injection molding technology is poised to revolutionize the production of car parts and drive the automotive industry towards a more efficient and eco-conscious future.