Introduction

When you think of LEGO, what comes to mind? Colorful bricks, endless creative possibilities, and maybe a few sore feet from stepping on them! But have you ever wondered about the manufacturing process behind these iconic toys? In this exploration, we’ll dive deep into how LEGO bricks are produced and clarify whether are Legos injection molded.

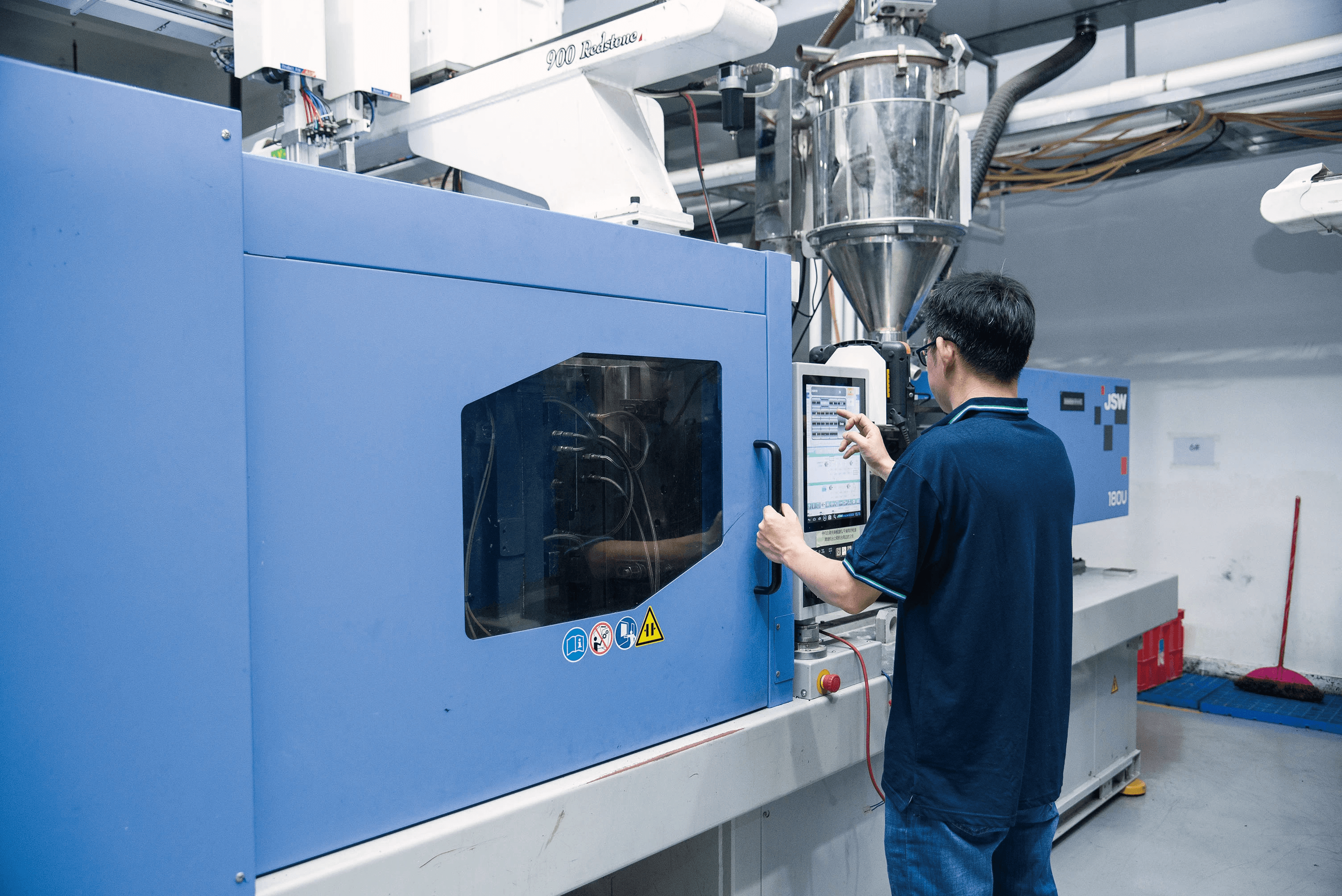

Understanding Injection Molding

Injection molding is a fascinating process that transforms raw plastic into intricate shapes, and it's the backbone of many industries. This method involves injecting molten plastic into a mold where it cools and solidifies into the desired form. With its efficiency and versatility, injection molding is not just used for toys; it’s also responsible for countless everyday products that we often take for granted.

The LEGO Manufacturing Process

So, what is the process of making Legos? It all begins with high-quality plastic pellets that are melted down in an injection molding machine. Once liquefied, this plastic is injected into precision molds to create those beloved LEGO bricks—ensuring each piece fits perfectly with every other one. This meticulous process guarantees durability and consistency across millions of bricks produced each year.

Common Myths About LEGO

Despite their popularity, there are several common myths surrounding LEGO manufacturing that deserve debunking. For instance, many people wonder if Legos get moldy or if they’re made from materials that break down easily over time. Additionally, some might assume that all plastic toys are created equal when it comes to quality; however, the precision involved in how LEGO bricks are moulded sets them apart from other injection-moulded products.

Are Legos Injection Molded?

When we delve into the world of LEGO, a common question arises: are Legos injection molded? The answer is a resounding yes! Understanding the intricacies of how LEGO bricks are manufactured not only reveals the magic behind these iconic toys but also highlights the importance of injection molding in creating durable and precise pieces that fit together seamlessly.

Definition of Injection Molding

Injection molding is a manufacturing process where molten plastic is injected into a mold to create specific shapes. This technique allows for high-volume production while maintaining consistency and precision, making it ideal for items like LEGO bricks. Essentially, it’s how plastic becomes your favorite building blocks, ensuring each piece is uniform and ready for imaginative play.

The Role of Injection Molding in LEGO

In the case of LEGO, injection molding plays a crucial role in producing those colorful bricks we all know and love. Each brick must meet strict quality standards to ensure compatibility with other pieces, and this is where injection molding shines. By using specialized molds, LEGO can create thousands of identical bricks quickly and efficiently—perfect for keeping up with demand!

Why LEGO Uses Injection Molding

So why does LEGO rely on this method? For starters, injection molding allows for incredible precision; each brick must fit perfectly with others to create stable structures during playtime. Additionally, using an injection molding machine enables LEGO to produce large quantities at once without sacrificing quality or detail—something essential when you consider that over 600 billion Lego pieces have been made since their inception!

What is the process of making legos?

The process of making LEGOs is a fascinating blend of technology and creativity, ensuring that each piece meets the high standards set by the company. From the initial design to the final product, every step is meticulously planned and executed. So, let’s dive into how these colorful bricks come to life.

Steps in the LEGO Production Process

The journey begins with design engineers who create digital models of new LEGO sets using advanced software. Once a design is finalized, it’s time for production, where an injection molding machine plays a key role in shaping those iconic bricks. The plastic pellets are heated until they melt and then injected into specially crafted molds—this is where we answer the question: are LEGOs injection molded? After cooling, the molds open to reveal perfectly formed bricks ready for assembly.

Once produced, these bricks go through several quality checks before being packaged for shipping. Each step ensures that every piece fits together seamlessly with others—after all, nobody wants a rogue brick ruining their masterpiece! The entire process showcases how efficient and precise LEGO manufacturing truly is.

Materials Used in LEGO Production

When pondering what is the process of making LEGOs?, one cannot overlook the materials involved. Primarily made from acrylonitrile butadiene styrene (ABS), this plastic offers durability and flexibility—essential traits for any toy meant to withstand hours of playtime. It’s not just about color; ABS can be easily molded into intricate shapes while maintaining its structural integrity.

Additionally, LEGO has committed to sustainability by exploring alternative materials like bio-based plastics derived from sugarcane. This shift not only enhances their product line but also addresses environmental concerns—a win-win for both kids and planet Earth! As they continue innovating with materials, one might wonder if other toys use similar methods or what objects are injection molded alongside LEGOs.

Quality Control in LEGO Manufacturing

Quality control in LEGO manufacturing isn’t just an afterthought; it’s woven into every stage of production to ensure that consumers receive nothing short of perfection. Each batch undergoes rigorous testing for color consistency, strength, and fit—because let’s face it: nobody wants their castle collapsing due to a faulty brick! This dedication helps answer another burning question: do LEGOs get moldy? With proper care and storage practices outlined later on, these toys can last generations without issues.

Moreover, advanced technology aids quality assurance efforts; cameras scan each brick as it exits the molding machine to catch defects early on. By prioritizing quality at every step—from material selection all the way through final inspection—LEGO maintains its reputation as a beloved brand worldwide. So next time you build your dream creation with those colorful blocks or ponder how are LEGO bricks moulded?, remember there’s a whole world behind each tiny piece!

What objects are injection Moulded?

Injection molding is a process that shapes materials into a variety of forms, and it’s not just LEGO bricks that benefit from this technology. The world around us is filled with everyday products that are injection molded, showcasing the efficiency and adaptability of this manufacturing method. From household items to automotive parts, injection molding plays a crucial role in producing components we often take for granted.

Everyday Products Made by Injection Molding

When you consider what objects are injection molded, think about your favorite kitchen gadgets or the plastic containers you use daily. Items like bottle caps, toys (including those LEGO bricks!), and even complex components in electronics are all produced through this efficient process. The remarkable thing is that these products can be made quickly and in large quantities, ensuring they’re available whenever we need them.

The versatility of injection molding doesn't stop there; medical devices, automotive interior parts, and even furniture pieces can be made using this method. This wide-ranging applicability demonstrates how essential injection molding is across various industries. So next time you reach for a plastic item, remember: it likely started its life as molten plastic in an injection molding machine!

The Versatility of Injection Molding

One of the standout features of injection molding is its ability to create intricate designs with precision and consistency—something LEGO fans appreciate deeply when pondering how are LEGO bricks moulded? This versatility allows manufacturers to produce everything from simple shapes to complex assemblies with ease. It’s not just about making toys; it's about creating reliable products that meet specific needs across different sectors.

Additionally, the speed at which products can be produced through this method means businesses can respond quickly to market demands without compromising on quality. Whether it’s crafting durable items or experimenting with innovative designs like those seen in LEGO sets today, the possibilities seem endless! As technology advances, we can expect even more creative uses for injection molding.

How LEGO Stands Out in Injection Molding

LEGO truly shines when it comes to how they utilize injection molding technology—it’s not just about being another name on the list of what objects are injection molded! Their commitment to quality ensures that every brick fits perfectly with others made decades ago—talk about impressive engineering! The precision required for such compatibility means that each mold must be crafted carefully using advanced techniques.

Moreover, LEGO has embraced sustainability within their manufacturing processes by exploring eco-friendly materials while maintaining high standards for durability and playability. This dedication sets them apart from many other brands utilizing similar methods like those who might sell a Lego injection mold for sale but lack the same ethos regarding quality or environmental responsibility. So next time someone asks if are Legos injection molded? you can confidently say yes—and highlight how they lead the charge in innovation!

Do Legos Get Moldy?

LEGO bricks are beloved by many, but the question arises: do Legos get moldy? While LEGO is made from durable plastic that resists moisture and decay, improper care can lead to issues. Understanding how to maintain your collection can ensure that your cherished bricks remain in top condition for years to come.

Factors Affecting LEGO Longevity

Several factors can impact the longevity of LEGO bricks, including environmental conditions and material quality. Exposure to humidity and extreme temperatures can degrade even the toughest plastics over time. Additionally, if LEGO bricks are stored in damp areas or without proper ventilation, the risk of mold growth increases significantly.

Best Practices for Keeping Legos Clean

To keep your LEGOs clean and in good shape, regular maintenance is key. Start by gently washing them with warm soapy water using a soft brush to remove dirt and grime—this helps prevent any build-up that could encourage mold growth later on. Moreover, avoid using harsh chemicals or abrasive materials that could scratch or damage the surface of your bricks.

Storage Tips to Prevent Mold

Proper storage is crucial for preventing mold on your LEGO collection. Store your bricks in a cool, dry place with good airflow; airtight containers can trap moisture, leading to unwanted surprises down the line. Consider using silica gel packets or moisture-absorbing products within storage bins to help regulate humidity levels and keep those colorful blocks safe from mold.

How are LEGO bricks moulded?

When it comes to the question of how LEGO bricks are moulded, the answer lies in a sophisticated blend of technology and artistry. The process is primarily centered around injection molding, a method that allows for precise shaping of plastic into the iconic interlocking blocks we all know and love. This technique is not just about creating toys; it's an intricate dance between machinery and material that ensures every piece meets LEGO's high standards.

The Molding Techniques Used in LEGO

LEGO utilizes advanced injection molding techniques to create its bricks, ensuring uniformity and durability across millions of pieces. In this process, plastic pellets are heated until they melt, then injected into meticulously crafted molds designed specifically for each type of brick. Once cooled, these molds produce the signature stud-and-tube design that allows for seamless connectivity—this is what makes us ask: Are Legos injection molded? Yes, indeed!

But it doesn’t stop there; LEGO employs various types of injection molding machines to cater to different production needs. From multi-cavity molds that allow for simultaneous production of multiple bricks to precision molds that ensure every detail is captured perfectly, the variety in techniques contributes significantly to the overall efficiency and quality control during manufacturing.

Importance of Precision in LEGO Manufacturing

Precision is paramount when it comes to manufacturing LEGO bricks because even a slight deviation can affect how well they fit together—something every avid builder knows all too well! Each brick must adhere to strict tolerances so that they can be easily assembled and disassembled without compromising their integrity over time. This focus on precision not only enhances user experience but also reinforces why questions like What is the process of making legos? lead back to their meticulous manufacturing methods.

Moreover, maintaining this level of precision requires constant monitoring throughout production using advanced technology and quality control measures. By investing heavily in both equipment and training for staff, LEGO ensures that each batch produced meets its high standards—a commitment evident in their enduring popularity as a toy.

Innovations in LEGO Moulding Technology

LEGO isn’t one to rest on its laurels; innovation plays a crucial role in keeping its manufacturing processes ahead of the curve. Recent advancements have introduced more sustainable materials into their production lines while enhancing efficiency—an essential step as consumers become increasingly environmentally conscious. These innovations often spark curiosity about What objects are injection moulded? as many industries look toward similar methods for sustainable practices.

Additionally, new technologies like 3D printing are being explored by LEGO as potential complements to traditional injection molding techniques. While conventional methods remain at the forefront due to their scalability and reliability, integrating innovative approaches could open up exciting possibilities for future product lines or custom creations—keeping fans engaged with questions like Do Legos get moldy? long after they've built their latest masterpiece.

Conclusion

In wrapping up our exploration of LEGO and its manufacturing processes, it’s clear that the world of LEGO is as colorful and intricate as the bricks themselves. From understanding if are legos injection molded? to learning about the various techniques involved in their production, we’ve uncovered a fascinating realm of creativity and innovation. As technology evolves, so too does LEGO manufacturing, promising exciting developments for future generations of builders.

The Future of LEGO Manufacturing

The future of LEGO manufacturing looks bright, especially with advancements in injection molding technology. As we delve deeper into What is the process of making legos?, we see that innovations like sustainable materials and eco-friendly practices are becoming more prevalent. With an increasing demand for environmentally conscious products, LEGO is poised to lead the charge in producing toys that are not only fun but also responsible.

Why LEGO Remains a Favorite Toy

LEGO’s enduring popularity can be attributed to its ability to inspire creativity across all ages. Whether you’re building a simple structure or tackling complex designs, Do Legos get moldy? becomes irrelevant when you consider the joy they bring. The versatility found in What objects are injection Moulded? with LEGO sets allows for endless possibilities—making it a timeless favorite among children and adults alike.

Exploring LEGO Beyond Just Blocks

LEGO has evolved far beyond just simple building blocks; it's now a cultural phenomenon that includes movies, video games, and themed experiences worldwide. The question How are LEGO bricks moulded? leads us into a world where imagination meets engineering excellence—resulting in unique designs that captivate fans everywhere. So next time you're admiring your collection or considering purchasing a Lego injection mold for sale, remember that each piece represents not just plastic but countless hours of fun and creativity.