Introduction

In the world of manufacturing, custom injection molding stands out as a versatile and efficient method for producing high-quality plastic parts. However, understanding custom injection molding costs can be a daunting task for many businesses looking to optimize their production processes. From material choices to design complexity, various factors influence how much does a custom injection mold cost, making it essential for decision-makers to grasp these elements before diving into production.

Understanding Custom Injection Molding Costs

When considering how much does injection molding cost in China versus domestic options, it's crucial to evaluate the broader landscape of expenses involved. The initial investment in mold creation can vary significantly based on several parameters such as material selection and production volume. By understanding injection mold cost for parts and the overall pricing structure, companies can make informed decisions that align with their budgetary constraints.

Key Factors Affecting Costs

Several key factors affect custom injection molding costs that every manufacturer should consider. Material selection plays a pivotal role; different plastics come with varying price tags and performance characteristics that can impact your final product's quality and durability. Additionally, the complexity of your design and mold will also dictate how much does injection molding cost per part, further complicating the budgeting process.

Why Choose Custom Injection Molding

Choosing custom injection molding offers numerous advantages that often outweigh its costs when approached strategically. This method allows for high precision and repeatability in producing intricate designs at scale—qualities that are hard to achieve with other manufacturing techniques. Moreover, using an injection mould cost calculator can help businesses accurately assess their expenses while considering long-term savings on large production runs.

What Affects Custom Injection Molding Cost

Understanding the various factors that influence custom injection molding cost is essential for anyone looking to dive into this manufacturing process. From material selection to production volume, each element plays a critical role in determining the final price tag. Let's explore these aspects in detail to help you make informed decisions.

Material Selection and Its Impact

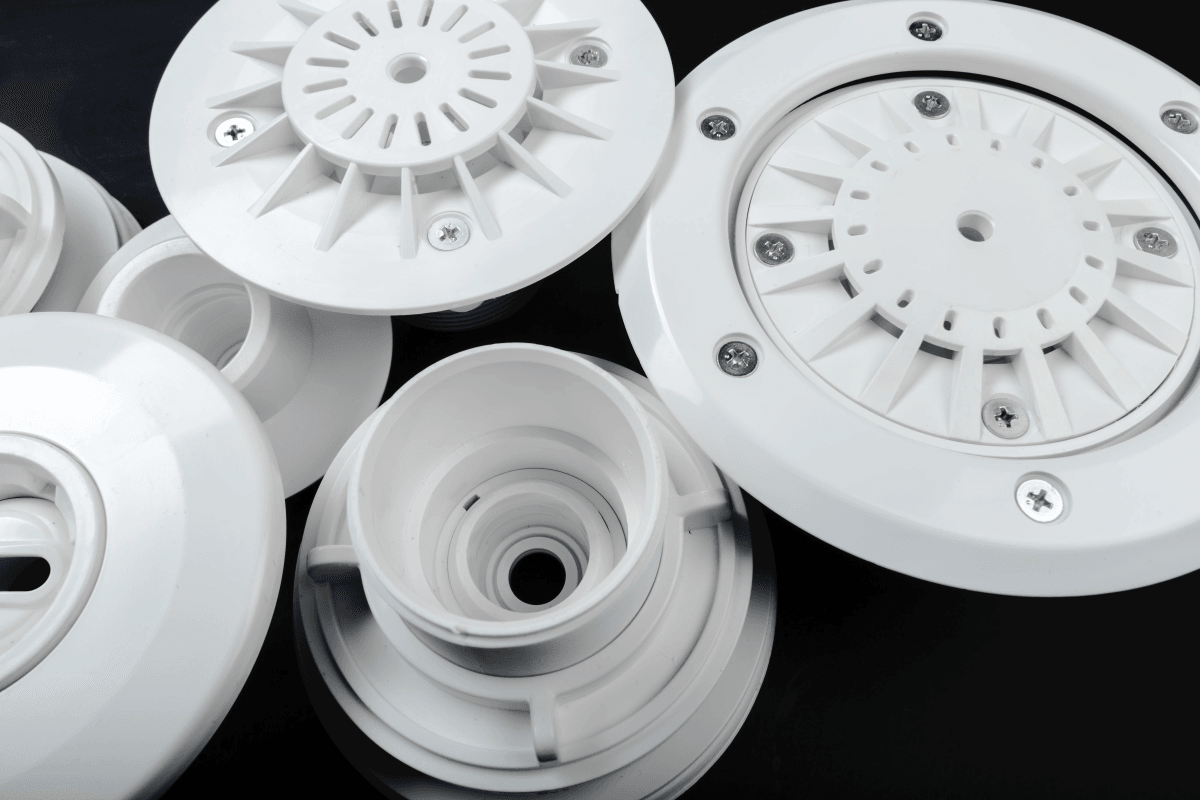

The choice of materials is one of the most significant factors affecting custom injection molding cost. Different materials come with varying price points, properties, and processing requirements, which can dramatically alter overall expenses. For instance, high-performance thermoplastics may be more expensive than standard plastics but could offer enhanced durability or temperature resistance—qualities that might justify their higher costs.

When asking how much does a custom injection mold cost?, it’s crucial to consider how your material choices will influence not just the mold creation but also production runs. The type of resin selected can impact cycle times and energy consumption during manufacturing, adding to the overall understanding of injection mold cost for parts. Ultimately, selecting the right material balances performance needs with budgetary constraints.

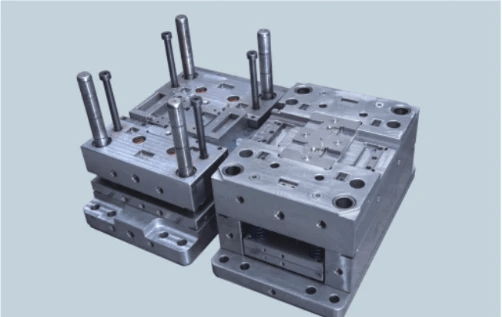

Complexity of Design and Mold

Another vital factor influencing custom injection molding costs is the complexity of your design and mold itself. Intricate designs require more sophisticated molds, which can lead to increased labor costs and longer lead times for production. If your design includes undercuts or requires multiple cavities, expect additional expenses due to the need for specialized tooling.

In terms of how much does injection molding cost per part?, keep in mind that complex molds often lead to higher initial costs but may reduce per-part pricing in larger runs due to efficiency gains over time. Understanding Injection Mold Cost for Parts involves recognizing that while upfront investments may be steep, they can pay off if designed correctly from the start. Therefore, investing time in optimizing your design could yield significant savings down the line.

Production Volume Considerations

Production volume is a key player when it comes to custom injection molding costs; it directly affects both unit pricing and overall project feasibility. Generally speaking, higher volumes tend to lower per-part costs as fixed expenses are spread across more units produced—a classic case of economies of scale at work! However, if you're considering a small batch run, you might find that initial setup fees disproportionately inflate your costs.

When pondering how to calculate injection molding cost?, remember that production volume influences not just material usage but also labor and machine time—two other significant components contributing to total expenses. Additionally, understanding how much does injection molding cost in China compared to domestic options often reveals stark contrasts based on local market conditions and labor rates associated with different volumes produced overseas versus locally manufactured items.

How Much Does a Custom Injection Mold Cost?

When diving into the world of custom injection molding, one of the first questions that comes to mind is, How much does a custom injection mold cost? The answer isn't straightforward, as various factors play a significant role in determining the overall expense. From material selection to design complexity, understanding injection mold costs for parts can help you make informed decisions for your projects.

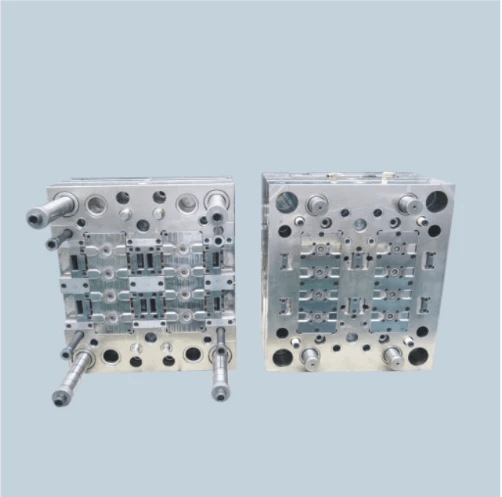

Pricing Breakdown of Mold Creation

The pricing breakdown of mold creation typically includes several components: initial design costs, material expenses, and manufacturing labor. On average, creating a custom injection mold can range from $1,000 to over $100,000 depending on these variables. For instance, simple molds made from aluminum may be more affordable than complex steel molds designed for high-volume production.

Another important aspect to consider is how much does injection molding cost per part? This will depend on the total number of parts produced and the intricacies involved in each part's design. Generally speaking, lower production volumes lead to higher costs per part due to fixed setup expenses being spread over fewer units.

Factors Influencing Mold Pricing

Several key factors influence custom injection molding costs and ultimately affect how much does a custom injection mold cost? Material selection is paramount; different plastics have varying price points and properties that impact durability and functionality. Additionally, if your design requires intricate features or tight tolerances, expect increased machining time and labor costs.

Production volume also plays a crucial role—higher volumes typically reduce the cost per part due to economies of scale. Furthermore, geographical location can significantly sway pricing; for example, how much does injection molding cost in China? Often lower than domestic prices due to reduced labor costs and overheads.

Real-World Examples of Pricing

To put things into perspective regarding understanding injection mold cost for parts, let’s look at some real-world examples. A basic single-cavity aluminum mold might start around $2,500 but could climb as high as $10,000 based on complexity and specifications. Conversely, multi-cavity steel molds designed for high-volume runs can easily exceed $50,000 or even reach upwards of $100,000 depending on their intricacy.

It's also helpful to utilize an injection mould cost calculator when estimating your project's needs; this tool allows you to input specific details about your project for more accurate pricing estimates tailored to your requirements. Remember that while upfront costs are essential considerations in budgeting for prototyping and production phases alike—long-term efficiency should also be factored into your overall financial planning.

Injection Molding Cost Variations by Location

How Much Does Injection Molding Cost in China?

So, how much does injection molding cost in China? Generally speaking, the cost is often lower than in many Western countries due to cheaper labor and operational expenses. However, while the upfront costs may be attractive, companies must also consider factors like quality control and communication barriers that could affect the final product.

In China, a custom injection mold can range from a few thousand dollars for simpler designs to tens of thousands for more complex projects. This price variability stems from aspects such as material choice and mold intricacy—key components when calculating your injection molding cost. Additionally, understanding injection mold cost for parts becomes essential when assessing the total investment involved.

Comparing Costs: Domestic vs. International

When comparing domestic versus international costs for custom injection molding services, it's important to weigh both financial implications and logistical challenges. While international options like China may offer lower initial quotes, hidden costs can arise through shipping fees or potential tariffs that inflate your overall budget. On the flip side, domestic manufacturers might charge more upfront but often provide faster turnaround times and easier communication.

How much does a custom injection mold cost domestically? Prices can vary widely based on location and supplier reputation; however, you might find that investing slightly more domestically pays off in terms of reliability and quality assurance over time. Ultimately, businesses must ask themselves how to calculate injection molding costs effectively by factoring in all these elements before making a decision.

Shipping and Import Fees

Shipping and import fees are critical components when considering your overall custom injection molding cost from overseas suppliers. Even if you score an excellent deal on manufacturing prices abroad, those savings can quickly evaporate with hefty shipping charges or customs duties upon arrival at your doorstep. It’s wise to factor these additional costs into your budget early on.

When evaluating how much does injection molding cost per part from an international supplier like those found in China or Southeast Asia, don't forget about logistics! Using an injection mould cost calculator can help you estimate not just production but also transportation expenses accurately—ensuring there are no surprises down the line. Ultimately, understanding all facets of shipping will empower businesses to make informed decisions regarding their manufacturing strategies.

Calculating Your Injection Molding Costs

How to Calculate Injection Molding Cost?

To figure out your custom injection molding cost, start by considering several key elements: material selection, mold complexity, and production volume. Each of these factors contributes to the overall price; for instance, high-quality materials may boost costs but yield better durability. Once you have these details in hand, you can use them in a formula that encompasses fixed and variable expenses associated with the project.

Additionally, don’t forget about overheads—these sneaky little fees can add up quickly if you're not careful! To get a clearer picture of “how much does a custom injection mold cost?”, remember that initial investments in tooling will be offset by long-term production savings as your volume increases. Thus, having a comprehensive understanding of all variables involved is essential for accurate calculations.

Using an Injection Mould Cost Calculator

An injection mould cost calculator can be your best friend when determining project expenses. These handy tools allow you to input various parameters like material type, mold complexity, and expected production runs to generate an estimated cost breakdown quickly. It’s particularly useful for those who are asking themselves “how much does injection molding cost per part?” since it provides insight into per-unit pricing based on your specifications.

Not only do calculators streamline the process, but they also offer comparative insights against industry standards—helpful for ensuring you're not getting taken for a ride! Just input your data and watch as it churns out numbers that help demystify what might initially seem like daunting figures regarding custom injection molding costs.

Understanding Injection Moulding Cost Per kg

Understanding injection moulding cost per kg is vital if you're looking to maximize efficiency while keeping an eye on budget constraints. This metric allows you to evaluate material usage against overall production costs effectively; after all, some materials are more expensive than others! By calculating costs on a per-kilogram basis, you'll gain valuable insight into which materials provide the best value without compromising quality.

Moreover, knowing this figure helps when comparing prices internationally—especially if you've been pondering “how much does injection molding cost in China?” The lower labor rates there might make certain projects more feasible financially even after shipping fees are factored in! Ultimately, having clarity around this metric empowers you to make informed decisions about materials and processes as you navigate through your custom injection molding journey.

Cost per Part: What to Expect

When diving into the world of custom injection molding, one of the most pressing questions is, How much does injection molding cost per part? This cost can vary widely based on several factors, including material choice, part complexity, and production volume. To give you a clearer picture, understanding Injection Mold Cost for Parts is crucial in budgeting for your projects.

How Much Does Injection Molding Cost Per Part?

The cost per part in custom injection molding typically ranges from a few cents to several dollars depending on various factors. For instance, if you're using high-end materials or intricate designs, expect the price to climb significantly. Additionally, lower production volumes often lead to higher costs per unit due to fixed setup expenses being spread over fewer parts.

To get a more accurate estimate of how much does a custom injection mold cost? It's wise to consult with manufacturers who can provide tailored quotes based on your specific needs and requirements. Remember that while initial costs may seem daunting, the long-term benefits of efficient mass production can lead to significant savings.

Analyzing Long-term Cost Efficiency

When evaluating custom injection molding cost, it’s essential to consider long-term efficiency rather than just upfront expenses. While the initial investment might be higher for unique designs or specialized materials, these costs can be offset by reduced manufacturing times and increased output over time. Therefore, analyzing how much does injection molding cost per part becomes crucial as production scales up.

Moreover, utilizing an Injection mould cost calculator can help forecast not only individual part costs but also project overall expenses as you ramp up production volumes. This tool allows businesses to simulate various scenarios and make informed decisions about materials and designs that maximize efficiency without sacrificing quality.

Budgeting for Prototyping and Production

Budgeting effectively for both prototyping and large-scale production is key when considering custom injection molding projects. Initial prototyping may incur higher costs due to lower quantities produced; however, this stage is vital for testing design viability before committing to mass production runs. Understanding Injection Moulding cost per kg during this phase will help you allocate resources wisely.

As you transition from prototype development into full-scale manufacturing, it's important to revisit those initial calculations—how much does injection molding cost in China?—and compare them with domestic options if applicable. By doing so, you'll have a comprehensive view that aids in making sound financial decisions while ensuring quality outcomes throughout your project lifecycle.

Conclusion

In the world of manufacturing, understanding custom injection molding costs can be a game changer for businesses and entrepreneurs alike. The intricacies of how much does a custom injection mold cost? depend on various factors including material choice, design complexity, and production volume. Ultimately, having a clear grasp of these elements is essential for budgeting and planning your projects effectively.

Summarizing Custom Injection Molding Costs

When it comes to custom injection molding costs, there’s no one-size-fits-all answer; it varies widely based on materials and design specifications. Understanding injection mold cost for parts is crucial in estimating overall project expenses. Additionally, knowing how much does injection molding cost per part can help you assess the long-term viability of your production plans.

Making Informed Decisions for Projects

To make informed decisions regarding your projects, it’s vital to consider all the variables that impact custom injection molding costs. Utilizing an injection mould cost calculator can simplify this process by providing quick estimates based on your specific requirements. Moreover, understanding how to calculate injection molding cost will empower you to negotiate better with suppliers and optimize your budget.

Future Trends in Injection Molding Pricing

The landscape of custom injection molding is continuously evolving, with trends indicating fluctuating prices due to global market dynamics. For instance, knowing how much does injection molding cost in China compared to domestic options can influence sourcing strategies significantly. As technology advances and sustainability becomes paramount, future pricing models may also shift towards eco-friendly materials and processes—keeping an eye on these trends will be key for savvy manufacturers.