Introduction

Injection molding is a cornerstone of modern manufacturing, offering efficiency and precision in creating complex plastic parts. However, understanding injection molding mold cost can be a daunting task for many businesses. With questions like How much does a mold for injection molding cost? frequently arising, it's essential to delve into the various components that contribute to these expenses.

Understanding Injection Molding Mold Cost

The injection molding mold cost encompasses multiple factors, including material selection, design intricacies, and production volume. Each of these elements plays a significant role in determining the overall price tag associated with creating molds for injection molded products. When considering how much does injection molding cost in China compared to other regions, it's clear that geographical location also influences expenses significantly.

Key Factors Influencing Mold Expenses

Several key factors influence mold expenses in the world of injection molding. These include the complexity of the part design and the materials used to create the molds themselves. Furthermore, understanding how to calculate injection mold cost effectively can help businesses budget more accurately and avoid unexpected financial pitfalls down the line.

The Importance of Accurate Cost Analysis

Accurate cost analysis is critical for any company looking to optimize its manufacturing processes and maintain profitability. By thoroughly assessing all aspects related to injection molding costs—including machine expenses and per kg pricing—companies can make informed decisions that enhance their bottom line. Ultimately, being well-versed in these financial dynamics will empower manufacturers to negotiate better deals and improve their production efficiency.

The Anatomy of Injection Molding Mold Cost

Understanding the anatomy of injection molding mold cost is crucial for manufacturers looking to optimize their production processes. This section delves into the various components that contribute to the overall cost, providing insights that can help in budgeting and decision-making. By breaking down these costs, businesses can better assess their financial strategies and identify potential savings.

Breakdown of Material Costs

Material costs are one of the most significant factors influencing injection molding mold cost. The type of resin used, along with its quality and availability, directly impacts how much does a mold for injection molding cost? For example, specialized materials like high-performance thermoplastics may come with a premium price tag, while more common resins tend to be more economical.

Additionally, fluctuations in raw material prices can affect overall expenses significantly. If you're wondering how much does injection molding cost in China compared to other regions, it’s essential to consider local material availability and pricing as key variables. Thus, understanding material costs not only helps in calculating injection mold costs but also aids in making strategic sourcing decisions.

Labor and Design Expenses

Labor and design expenses are another critical aspect of injection molding costs that often go unnoticed until it's too late. Skilled labor is required for both the initial design phase and ongoing production processes, which can add up quickly when assessing total project expenses. Moreover, intricate designs may necessitate additional engineering hours or specialized labor—factors that can significantly inflate your budget.

When evaluating how to calculate injection mold cost accurately, it’s essential to include these labor components alongside material expenses. Understanding these nuances helps manufacturers make informed decisions about whether to outsource certain tasks or invest in training their workforce for efficiency gains. Ultimately, optimizing labor-related costs can lead to substantial savings over time.

Tooling and Maintenance Considerations

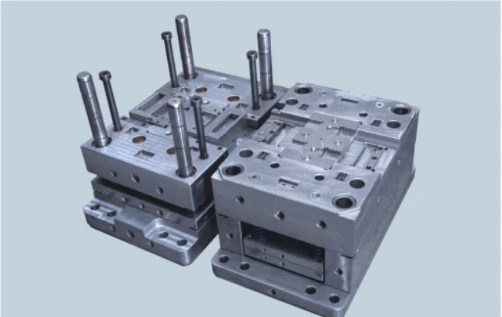

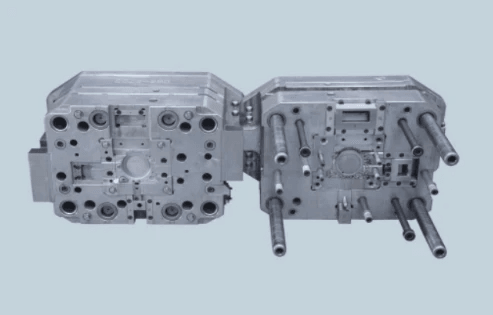

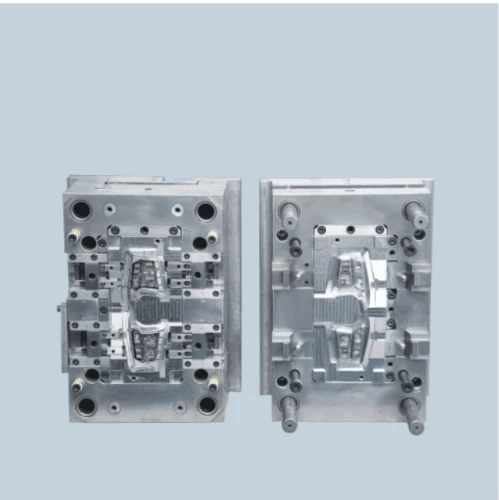

Tooling and maintenance are pivotal elements that cannot be overlooked when discussing injection molding mold cost. High-quality molds often require substantial upfront investment; however, they tend to offer better longevity and performance over time—an important consideration if you’re pondering how much does an injection molding machine cost? Regular maintenance also plays a vital role in preserving mold integrity; neglecting this aspect could lead to costly repairs or even premature replacements.

Furthermore, understanding tooling options—from standard molds to custom designs—can impact your bottom line significantly as well as influence how much does injection molding cost per kg during production runs. Investing wisely in tooling not only reduces immediate expenses but also enhances productivity by minimizing downtime caused by repairs or adjustments later on. In summary, thorough attention to tooling and maintenance considerations is essential for sustainable manufacturing practices.

Exploring Global Costs

When it comes to injection molding, understanding the global landscape of costs is essential for businesses looking to optimize their production expenses. The intricacies of injection molding mold cost vary widely across different regions, influenced by factors such as labor rates, material availability, and economic conditions. This section will delve into how much injection molding costs in China, compare costs across various regions, and examine the economic factors that impact pricing.

How Much Does Injection Molding Cost in China?

China has become a powerhouse in manufacturing due to its competitive pricing and efficient production capabilities. So, how much does injection molding cost in China? Generally speaking, the injection molding mold cost can range from a few thousand dollars for simpler molds to tens of thousands for more complex designs. Additionally, the low labor costs contribute significantly to reducing overall expenses, making China an attractive option for many businesses looking to cut down on production costs.

However, it's important to consider that while initial mold costs might be lower in China, other factors such as shipping fees and potential tariffs can affect your bottom line. Therefore, when asking how much does injection molding cost per kg or how much does a mold for injection molding cost specifically from Chinese manufacturers, one must factor in these additional expenses as well. Ultimately, effective communication with suppliers is key to ensuring transparency about all associated costs.

Comparing Costs in Different Regions

When comparing injection molding costs globally, it's essential to recognize that prices fluctuate based on geographical location and local economies. For instance, while countries like India and Vietnam offer competitive rates similar to China's low-cost production model, North America and Europe often have higher labor rates that increase overall injection molding costs significantly. Thus arises the question: how much does an injection molding machine cost when considering these regional differences?

Moreover, quality also varies by region; some manufacturers may provide lower upfront prices but compromise on quality or lead times—factors crucial for long-term projects where durability matters most. So when evaluating where to produce your parts or molds based on cost alone—remember that what you pay upfront may not reflect total value over time! Understanding these nuances can help businesses make informed decisions regarding their supply chain strategies.

The Impact of Economic Factors on Pricing

Economic factors play a pivotal role in shaping the landscape of injection molding costs worldwide. Currency fluctuations can affect pricing dramatically; for example, if you are sourcing from a country with a depreciating currency against your own dollar value might shift unexpectedly! Additionally, inflation rates within different regions can also lead manufacturers to adjust their prices accordingly.

Supply chain disruptions—such as those seen during global crises—further complicate matters by increasing raw material prices and shipping fees alike; this directly impacts how much does injection molding cost per kg or even how much does an injection mold for injection molding actually end up costing you at checkout! Consequently,, staying updated with market trends is vital if you're keen on maintaining budgetary control over your manufacturing processes while still achieving high-quality results.

Cost Calculation Techniques

How to Calculate Injection Mold Cost?

Calculating injection mold costs involves several key components that contribute to the overall expense. First, consider material costs, which include not only the type of resin used but also any additives that may enhance product performance. Next, factor in labor and design expenses, as skilled professionals are necessary for crafting molds that meet precise specifications.

To determine how much does injection molding cost per kg, you'll need to evaluate production volume alongside material waste during the process. The more units produced, the lower your per-unit cost will be; however, initial setup and tooling can significantly impact your overall budget. By breaking down these elements into manageable parts, you can create a comprehensive estimate of your injection molding mold cost.

Utilizing Software for Accurate Estimates

In today’s fast-paced manufacturing environment, leveraging technology is crucial for obtaining accurate estimates of injection molding costs. Various software programs are designed specifically to assist engineers and project managers in calculating how much does an injection molding machine cost and related expenses efficiently. These tools can analyze multiple variables simultaneously—like material choices and production timelines—to provide real-time updates on projected costs.

Additionally, many of these software solutions allow users to input specific parameters unique to their projects—ensuring that your calculations reflect actual conditions rather than generic estimates. Utilizing software not only streamlines the costing process but also enhances accuracy by reducing human error in calculations related to injection molding costs.

Real-World Examples and Case Studies

Examining real-world examples provides valuable insights into how companies manage their injection molding mold costs effectively. For instance, one case study highlighted a manufacturer who initially struggled with high expenses due to inefficient machinery; they discovered that investing in quality equipment drastically reduced long-term operational costs while improving production efficiency—demonstrating how much does an injection molding machine cost can influence overall profitability.

Another example involved a company analyzing its approach regarding how much does injection molding cost in China versus domestic manufacturing options; they found significant savings by sourcing materials from overseas while maintaining quality standards through meticulous supplier selection processes. These case studies underscore the importance of strategic planning when evaluating various factors influencing your total investment in injection molding processes.

Evaluating Machine Expenses

How Much Does an Injection Molding Machine Cost?

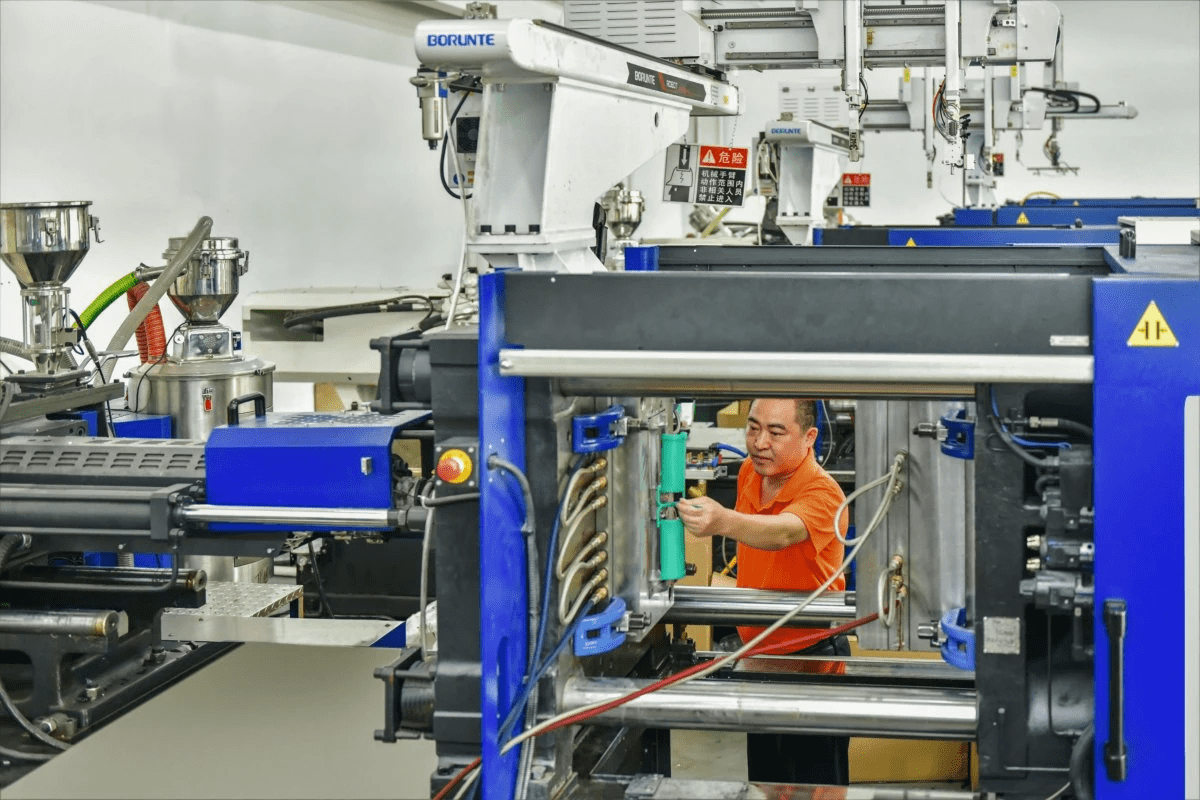

The cost of an injection molding machine can vary widely based on factors such as size, capability, and manufacturer reputation. On average, you might find prices ranging from $10,000 for smaller machines to over $100,000 for larger or more advanced models. When considering how much does an injection molding machine cost, it's essential to factor in potential additional expenses like installation and training for operators.

Understanding how much does a mold for injection molding cost also plays a role here; often the machinery needs to be compatible with specific molds which can drive up costs further. Additionally, regional pricing differences should not be overlooked—how much does injection molding cost in China? In many cases, manufacturers in China offer competitive pricing on machinery compared to Western counterparts due to lower labor costs and material availability.

Understanding the Total Cost of Ownership

Calculating the total cost of ownership (TCO) goes beyond just the sticker price of the equipment; it includes maintenance fees, energy consumption, and depreciation over time. For instance, while a cheaper machine may seem appealing upfront, higher maintenance costs could make it less economical in the long run compared to a slightly pricier but more reliable model. Therefore, when pondering how to calculate injection mold cost accurately, always include TCO as part of your analysis.

Moreover, consider how often you'll need replacement parts or service visits—these can add up quickly if your machine isn't built for durability or efficiency. Remember that quality machines may have higher initial costs but can lead to savings down the line through reduced downtime and lower operational expenses.

Long-Term Savings Through Quality Machines

Investing in high-quality injection molding machines ultimately pays off by increasing productivity and reducing waste during production runs. Quality machines tend not only to last longer but also operate more efficiently—leading directly into discussions about how much does injection molding cost per kg? A well-functioning machine minimizes scrap rates and optimizes material usage which is key when calculating per-kilo pricing dynamics.

In addition to operational efficiency, quality machines often come with better technology that enhances precision—this helps ensure that each mold produced meets stringent specifications without costly reworks or adjustments later on. As manufacturers look for ways to reduce their overall injection molding mold cost while maintaining quality standards, partnering with reputable suppliers becomes vital in achieving those goals effectively.

Per Kilo Pricing Dynamics

How Much Does Injection Molding Cost Per Kg?

The cost of injection molding per kilogram hinges on various elements such as the type of resin used and the intricacies of the design involved in creating the mold. For example, standard thermoplastics may be less expensive than specialized materials like high-performance polymers or composites. Additionally, when evaluating How much does injection molding cost in China? you might find that labor costs and material availability significantly influence pricing structures compared to other regions.

Understanding how to calculate injection mold cost effectively involves considering both fixed and variable expenses associated with production. This means not only accounting for raw material costs but also factoring in overheads linked with machine operation and maintenance. By doing so, businesses can develop a clearer picture of their overall expenditure per kilogram produced.

Factors Affecting Production Volume Costs

Production volume plays a significant role in determining overall costs associated with injection molding processes. Higher volumes typically lead to reduced costs per unit due to economies of scale; however, initial setup costs for molds can be substantial—especially when asking How much does a mold for injection molding cost? These upfront expenses can be offset by lower per-kilo prices when producing large quantities.

Furthermore, factors such as cycle time and machine efficiency also contribute significantly to production volume costs. The faster a machine operates without compromising quality, the more economical it becomes over time. Understanding these dynamics allows manufacturers to make informed decisions about scaling up operations while keeping an eye on their bottom line.

Strategies to Optimize Costs

To truly get a grip on reducing injection molding costs while maintaining quality standards, several strategies come into play. First off, selecting an efficient design that minimizes waste during production is key—this directly impacts both material usage and cycle times leading ultimately to lower overall expenses per kilogram produced.

Another effective approach is investing in high-quality machinery; while upfront costs may be higher—asking How much does an injection molding machine cost?—the long-term savings through reduced downtime and enhanced performance are often worth it. Additionally, partnering with experienced suppliers or consulting firms can provide insights into best practices that streamline operations further while addressing specific queries like How do I calculate my injection mold cost?

In summary, understanding the dynamics behind per kilo pricing within the context of injection molding enables businesses not only to budget effectively but also position themselves competitively within their respective markets.

Conclusion

In wrapping up our exploration of injection molding mold cost, it’s clear that understanding the various components can significantly impact your budget and production strategy. Key factors like material costs, labor, and regional pricing all play crucial roles in determining how much does a mold for injection molding cost? With a thorough analysis of these elements, businesses can make informed decisions that enhance profitability while maintaining quality.

Recap of Injection Molding Mold Cost Insights

Throughout this discussion, we delved into the anatomy of injection molding costs, highlighting material expenses, labor considerations, and tooling maintenance. We also examined global pricing variations by asking how much does injection molding cost in China? Understanding these insights is essential for anyone looking to optimize their production process and manage their expenses effectively.

Tips for Reducing Your Mold Expenses

To trim down your injection molding costs, consider implementing strategies such as bulk purchasing materials or investing in high-quality machines that offer long-term savings. Additionally, understanding how to calculate injection mold cost accurately can help you identify unnecessary expenditures. Streamlining your design process can also lead to significant reductions in overall costs—after all, every penny counts when you're working with injection molding!

Partnering with Experts Like Baoyuan for Quality Production

When navigating the complex world of injection molding costs, partnering with experts like Baoyuan can make all the difference. Their knowledge not only helps you understand how much does an injection molding machine cost but also assists in optimizing every aspect of your production line. By collaborating with seasoned professionals who know the ins and outs of the industry, you can ensure quality production while keeping an eye on those pesky mold expenses.