Introduction

The plastic mould market is a dynamic arena where innovation meets practicality, shaping the future of manufacturing. As the demand for plastic products continues to surge, understanding the nuances of plastic mould prices becomes essential for businesses and consumers alike. The rise of affordable mould options has opened doors for many, making quality plastic injection moulding services more accessible than ever.

Understanding the Plastic Mould Market

At its core, the plastic mould market revolves around creating precise and durable moulds that are essential in producing various plastic products. Plastic injection molding is a key process within this market, allowing manufacturers to create complex shapes with high efficiency and consistency. With an increasing number of players entering this field, it’s crucial to grasp how these changes impact overall pricing and service offerings.

Why Plastic Mould Prices Matter

Plastic mould prices play a pivotal role in determining the cost-effectiveness of production processes for businesses across industries. A well-priced mould can significantly reduce production costs while maintaining quality standards, ultimately influencing profit margins and competitiveness in the market. Understanding these price dynamics helps companies make informed decisions when selecting their plastic injection molding services.

The Rise of Affordable Mould Options

In recent years, there has been a notable shift towards more affordable options in the realm of mold plastic injection technology. Advances in manufacturing techniques and materials have enabled companies to offer competitive pricing without compromising on quality or performance. This trend not only benefits manufacturers but also empowers small businesses and startups to leverage high-quality injection moldable plastics at lower costs.

Overview of Plastic Injection Moulding Services

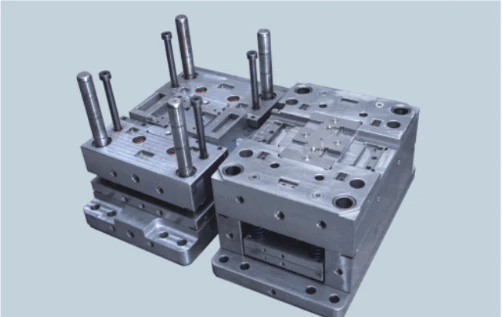

Plastic injection moulding is a transformative process that has revolutionized the manufacturing of plastic products. It involves injecting molten plastic into a pre-designed mould, which cools and solidifies to form the desired shape. This method is not only efficient but also allows for high precision, making it an ideal choice for businesses looking to produce intricate designs at scale.

What Is Plastic Injection Moulding

At its core, plastic injection moulding is a manufacturing technique that uses specialized machinery to create parts from thermoplastic or thermosetting polymers. The process begins with heating plastic pellets until they melt and become pliable before being injected into a mould under high pressure. Once cooled, the resulting product can be easily removed from the mould, ready for further processing or direct use.

This method stands out in the realm of production due to its ability to produce large volumes of identical items quickly and consistently. With advancements in technology, modern plastic injection molding services have become more accessible than ever, allowing even small businesses to leverage this efficient production method without breaking the bank on plastic mould prices. The versatility in design and material selection makes it a go-to option for manufacturers across various industries.

Benefits of Choosing Injection Molding

Choosing injection molding offers numerous benefits that can significantly impact both production efficiency and product quality. One major advantage is its cost-effectiveness; while initial costs may seem high due to mold creation, the long-term savings on large-scale production can outweigh these expenses dramatically when considering overall plastic mould price reductions over time. Additionally, this method minimizes waste by using only the necessary amount of material during production.

Another key benefit is design flexibility; complex shapes that would be challenging or impossible with other methods can be produced readily through this technique. Furthermore, injection molded parts exhibit excellent strength and durability, making them suitable for a wide range of applications—from everyday household items to critical automotive components—ensuring you get value for your investment in mold plastic injection services.

Lastly, rapid prototyping capabilities allow companies to test designs quickly before committing fully to mass production—a crucial factor in today’s fast-paced market where time-to-market can make or break success.

Key Players in the Industry

The landscape of plastic injection molding services features several key players who are leading innovations and setting standards within the industry. Companies like BASF and DuPont are recognized not just for their extensive ranges of materials but also their commitment to sustainable practices that appeal to environmentally-conscious consumers seeking eco-friendly options among injection moldable plastics.

On another front, manufacturers specializing in custom solutions—such as Protolabs and Xometry—are gaining traction by offering rapid turnaround times while maintaining competitive pricing structures on their molds and services without compromising quality standards. These organizations play an essential role in shaping market dynamics by driving down costs through technological advancements while enhancing service offerings tailored specifically toward client needs.

Factors Influencing Plastic Mould Price

When it comes to the plastic mould price, a myriad of factors come into play that can significantly affect the overall cost of plastic injection moulding services. Understanding these elements is crucial for businesses looking to optimize their production budgets while ensuring quality in their plastic products. From material selection to labor efficiency, each factor contributes uniquely to the final price tag.

Material Selection and Costs

The choice of materials is one of the most influential aspects affecting the plastic mould price. Different types of injection moldable plastics come with varying costs, which can dramatically impact your budget for plastic injection molding. For instance, high-performance thermoplastics may offer superior durability but often come at a premium compared to standard materials like polypropylene or polyethylene.

Moreover, sourcing quality materials can also lead to fluctuations in costs due to market demand and availability. When selecting a material for your mould plastic injection needs, it's essential to balance performance requirements with cost-efficiency. Ultimately, making informed decisions about material selection can help you achieve significant savings in your overall project.

Design Complexity and Its Impact

Design complexity plays a pivotal role in determining the plastic mould price as well. More intricate designs typically require advanced techniques and longer production times, leading to higher costs associated with custom molds and tooling setups within plastic injection molding services. The more detailed your design is, the more resources it demands—from engineering expertise to machine time—resulting in an increased price tag for your mould.

Additionally, complex designs may necessitate additional testing and adjustments during production phases, further driving up expenses. However, investing in thoughtful design can yield long-term benefits by enhancing product functionality and market appeal despite initial higher costs. Therefore, striking a balance between complexity and practicality is key when considering your options for mold plastic injection.

Labor and Production Efficiency

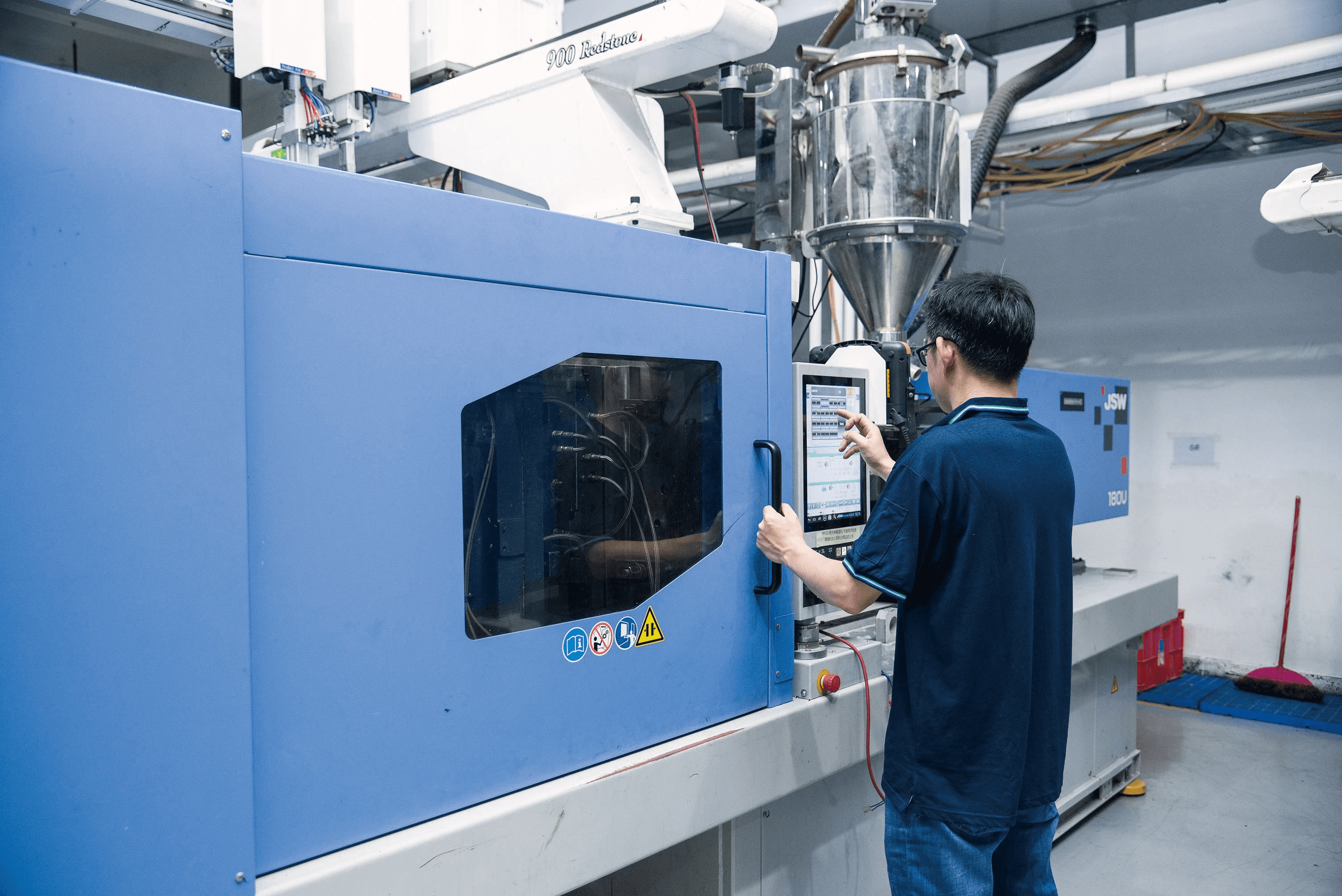

Labor costs are another critical factor influencing the overall pricing structure of plastic injection molding services. Skilled labor is essential for ensuring that production runs smoothly; however, wages vary widely based on location and expertise level within the industry. Investing in experienced professionals may raise initial expenses but often results in better-quality output and fewer costly mistakes down the line.

Production efficiency also plays a significant role; streamlined processes can reduce cycle times significantly while improving output quality—translating into lower per-unit costs over time. Companies that utilize advanced manufacturing technologies tend to enjoy enhanced efficiency levels that contribute positively towards reducing their overall mould prices as well as increasing competitiveness within the market for affordable options. In conclusion, optimizing labor practices alongside efficient production methods is vital for maintaining an attractive pricing strategy without compromising quality.

Exploring Affordable Plastic Injection Moulding Services

In today's competitive landscape, finding affordable plastic injection moulding services is essential for businesses looking to optimize production costs while maintaining quality. With the right strategies and knowledge, companies can navigate the complex world of plastic mould prices and discover budget-friendly options that don’t compromise on excellence. This section dives into popular companies, innovative practices, and the pros and cons of local versus overseas production.

Popular Companies Offering Competitive Pricing

When it comes to affordable plastic mould prices, several companies stand out for their commitment to providing value without sacrificing quality. Firms like XYZ Moulds and ABC Plastics have built reputations based on their competitive pricing structures paired with excellent customer service in the realm of plastic injection molding services. These companies often leverage economies of scale to offer lower costs while ensuring that their mould plastic injection solutions meet industry standards.

The key players in this space not only focus on price but also emphasize efficiency in their processes. By adopting advanced technologies and streamlined workflows, they can pass savings on to customers looking for cost-effective solutions for their plastic products. As a result, businesses can find reliable partners that cater specifically to budget-conscious projects without skimping on quality.

Innovations Driving Down Costs

Innovation is a significant driver behind the decreasing costs associated with plastic injection molding services today. New manufacturing techniques such as 3D printing prototyping allow for rapid design iterations without hefty expenses tied to traditional methods, ultimately leading to reduced overall production costs. Furthermore, advancements in materials science have introduced more affordable injection moldable plastics that maintain durability while being easier on the wallet.

Automation is another game-changer, as many companies are integrating robotics into their production lines to enhance efficiency and minimize labor costs associated with manual processes. These innovations not only help lower the initial plastic mould price but also improve turnaround times for clients seeking quick solutions for their projects. With ongoing advancements in technology, expect even more cost-effective options emerging in the market.

Local vs. Overseas Production

When considering where to source your mould plastic injection needs, businesses often face a choice between local manufacturers and overseas suppliers. Local production offers advantages such as shorter lead times and easier communication due to proximity; however, it may come with higher plastic mould prices compared to international options. On the other hand, overseas production can significantly reduce costs due to lower labor expenses but may introduce complexities related to shipping times and potential language barriers.

Ultimately, the decision boils down to individual project requirements and budget constraints—some businesses may prioritize speed over cost savings or vice versa when selecting between local versus international suppliers of injection molding services. It's essential for companies to weigh these factors carefully before committing resources so they can make informed decisions about where best to invest in their next batch of high-quality plastic products.

The Role of Baoyuan in the Mould Market

In the competitive landscape of plastic injection moulding services, Baoyuan stands out as a key player, known for its commitment to quality and affordability. With a deep understanding of the plastic mould market, Baoyuan has positioned itself as a trusted source for businesses seeking efficient and cost-effective solutions. By focusing on advanced techniques and skilled expertise, they ensure that their clients receive top-notch products without breaking the bank.

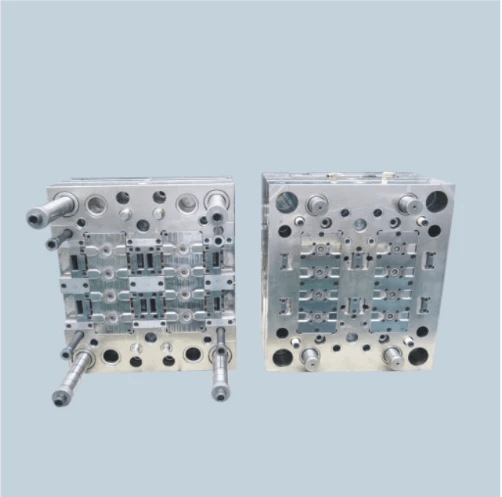

Expertise of the Baoyuan Team

The team at Baoyuan is comprised of seasoned professionals who bring years of experience in plastic injection molding to the table. Their expertise spans various aspects of mould design and production, enabling them to tackle projects ranging from simple to highly complex. This wealth of knowledge allows them to optimize each step in the process, ensuring that clients get the best possible value for their investment while keeping plastic mould prices competitive.

Furthermore, the team’s dedication to continuous learning ensures they stay ahead of industry trends and innovations. They are adept at utilizing cutting-edge technologies, which enhances their ability to produce high-quality moulds efficiently. As a result, Baoyuan not only meets but often exceeds customer expectations in delivering reliable plastic injection molding services.

Advanced Software Utilization for Cost Efficiency

Baoyuan leverages state-of-the-art software solutions that streamline design processes and enhance production efficiency in mould plastic injection projects. These advanced tools enable precise modeling and simulation before any physical production begins, reducing errors that could lead to increased costs down the line. By adopting such technology, Baoyuan can offer more accurate quotes on plastic mould prices while maintaining high standards for quality.

Additionally, this software integration allows for rapid prototyping—a crucial factor in today’s fast-paced market where time is money. Clients benefit from quicker turnaround times without sacrificing quality or detail in their designs for injection moldable plastics. Ultimately, this technological edge empowers Baoyuan to provide exceptional value through its plastic injection molding services.

Quality Assurance in Mould Production

Quality assurance is paramount at Baoyuan; it’s not just about producing affordable molds but ensuring they perform flawlessly over time. Rigorous testing protocols are implemented throughout every stage of production—from material selection right through to final inspection—guaranteeing that each product meets stringent industry standards. This unwavering commitment translates into reliable performance for customers using these molds in various applications within their own businesses.

Moreover, by prioritizing quality alongside cost efficiency, Baoyuan cultivates long-term relationships with clients who appreciate dependable service without compromising on excellence. They understand that a competitive plastic mould price doesn’t mean cutting corners; rather it involves smart strategies that enhance durability and functionality across all types of plastic products produced with their molds.

In conclusion, with its expert team and innovative practices focused on quality assurance and cost efficiency, Baoyuan plays an essential role in shaping the future landscape of affordable plastic injection molding services.

Injection Moldable Plastics: Your Best Choices

When it comes to plastic injection molding, the choice of materials can significantly impact both the end product and the overall plastic mould price. Understanding the various types of injection moldable plastics available is crucial for manufacturers seeking cost-effective and high-quality solutions. From versatile thermoplastics to durable thermosets, each material has its unique properties that cater to different applications in the realm of plastic products.

Types of Injection Moldable Plastics

The world of injection moldable plastics is vast and varied, with options like polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC) being some of the most popular choices in plastic injection molding services. Polypropylene is known for its lightweight nature and resistance to chemical stress, making it a go-to option for many consumer goods. Meanwhile, polyethylene boasts excellent flexibility and toughness, ideal for packaging applications; PVC offers durability and rigidity, perfect for construction-related projects.

Beyond these common types, there are also engineering plastics such as acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) that provide enhanced strength and heat resistance. These materials are often utilized when higher performance specifications are required in mould plastic injection processes. The diversity in available plastics means manufacturers can tailor their choices based on specific requirements while keeping an eye on overall costs.

Cost-Effectiveness of Various Plastics

When evaluating the cost-effectiveness of different plastics used in plastic injection molding services, factors such as raw material costs, processing expenses, and product longevity must be considered. For example, while certain high-performance plastics may have a higher upfront cost due to their specialized properties, they can lead to savings over time through reduced failure rates or longer lifespan in end products. This makes materials like nylon or polycarbonate worthwhile investments despite their initial expense.

On the other hand, more economical options like PP or PE can deliver excellent value without compromising quality for many standard applications—making them favorites among budget-conscious manufacturers looking at plastic mould price considerations. Ultimately, striking a balance between performance requirements and budget constraints is key when selecting materials for mold plastic injection projects.

Environmental Considerations in Material Choice

In today's eco-conscious market, environmental considerations play a significant role in determining which injection moldable plastics to use within manufacturing processes. Biodegradable alternatives such as polylactic acid (PLA) are gaining traction as sustainable options that minimize environmental impact while still meeting performance standards required by consumers today. Choosing such environmentally friendly materials not only helps reduce waste but also aligns with corporate social responsibility goals.

Moreover, recycling practices surrounding traditional plastics like PET are becoming increasingly important as companies look to lower their carbon footprint associated with production processes in plastic injection molding services. By selecting recyclable materials or incorporating recycled content into new products through mould plastic injection techniques, businesses can contribute positively towards sustainability efforts while potentially reducing overall costs tied to raw material procurement.

As manufacturers navigate these choices within the context of rising expectations surrounding environmental responsibility alongside competitive pricing pressures reflected in current plastic mould prices—it's clear that understanding both material properties and market dynamics will be vital moving forward.

Conclusion

In the dynamic world of plastic moulding, understanding the nuances of plastic mould price is essential for businesses aiming to optimize their production costs. The affordability of plastic injection moulding services has opened new avenues for innovation and efficiency, allowing companies to create high-quality plastic products without breaking the bank. As we navigate through various options, it becomes clear that informed decisions can lead to significant savings while maintaining quality standards.

Key Takeaways on Affordable Plastic Mould Pricing

When considering affordable plastic mould pricing, it's crucial to assess the factors that influence costs—ranging from material selection to design complexity. Companies offering plastic injection molding services have become increasingly competitive, leveraging technology and streamlined processes to provide cost-effective solutions. By understanding these dynamics, businesses can make smarter choices when investing in mould plastic injection.

The Future of Plastic Injection Moulding

The future of plastic injection moulding looks promising as advancements in technology continue to drive down costs and improve efficiency. Innovations such as automated production lines and advanced software are reshaping how manufacturers approach the creation of injection moldable plastics. With a focus on sustainability and cost-effectiveness, the industry is poised for growth while meeting environmental considerations head-on.

Navigating Your Options for Budget-Friendly Moulds

Navigating options for budget-friendly moulds requires a strategic approach that balances quality with affordability in the realm of plastic injection molding services. It's essential to research local versus overseas production capabilities, as both have their unique advantages and challenges regarding cost and delivery times. By keeping an eye on current trends and innovations within the market, businesses can effectively identify opportunities for savings while ensuring they choose reliable partners in mold plastic injection.