Introduction

When diving into the world of manufacturing, one of the first questions that arises is, How much does a plastic mold cost? Understanding plastic mold costs is crucial for businesses looking to optimize their production processes. With various factors influencing these costs, from material selection to intricate design elements, it’s essential to grasp the full picture.

Understanding Plastic Mold Costs

Plastic molds are vital in the injection molding process, serving as the blueprint for producing countless items we use daily. But how much do plastic molds cost? The answer varies widely based on several components that contribute to the overall price tag, making it imperative for manufacturers to conduct thorough research before investing.

Factors Influencing Mold Pricing

Several factors come into play when determining how much does a plastic mold cost. These include the complexity of the design, materials used, and even geographic location of production facilities. Additionally, understanding why plastic mold is expensive can help businesses budget accordingly and make informed decisions about their manufacturing strategies.

The Role of Design in Costs

The design phase plays a pivotal role in shaping both functionality and cost-efficiency when it comes to molds. A well-thought-out design can streamline production but may also raise initial expenses—leading many to wonder how much does plastic mold service cost in relation to its overall value? Ultimately, investing in quality design can lead to long-term savings and improved product output for manufacturers navigating this complex landscape.

How Much Does a Plastic Mold Cost?

Understanding how much does a plastic mold cost is essential for businesses looking to invest in manufacturing. The costs can vary significantly based on various factors, including complexity, materials, and design intricacies. This section will break down the components contributing to the overall price of plastic molds.

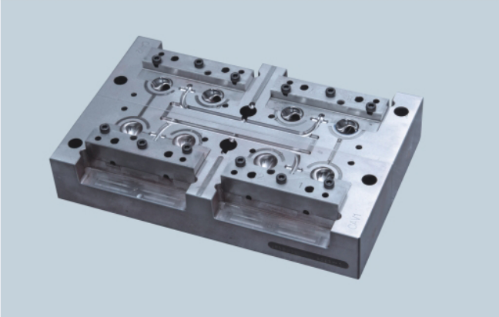

Breakdown of Cost Components

When considering how much do plastic molds cost, it's important to look at the different elements that contribute to the final price tag. Typically, costs include design fees, material expenses, machining labor, and finishing processes. Each of these components can add up quickly; for instance, intricate designs may require more sophisticated machinery and skilled labor, which increases the overall expense.

Material Choices Impacting Price

The choice of materials plays a significant role in determining how much does a plastic mold cost. For example, steel molds tend to be more expensive upfront but offer durability and longevity compared to aluminum options which are cheaper but may wear out faster. The type of plastic being molded also influences material selection; specialized plastics can drive up costs due to their unique properties.

Additionally, some materials may require special treatments or coatings that further increase expenses. When evaluating how much do plastic molds cost for your specific project or business needs, consider both initial investment and long-term performance based on material choices.

Average Price Ranges for Different Molds

So just how much do injection molding costs vary? On average, simple molds can start around $1,000 while more complex designs may range from $5,000 to $100,000 or even higher depending on specifications and production volume requirements. Generally speaking, larger orders often lead to reduced per-unit costs due to economies of scale—this is where bulk orders come into play!

For businesses looking at long-term investments versus short-term costs associated with mold production and maintenance (how much does plastic mold service cost), understanding these averages helps in making informed decisions about what fits best within budget constraints while ensuring quality output.

How Much Do Plastic Molds Cost for Businesses?

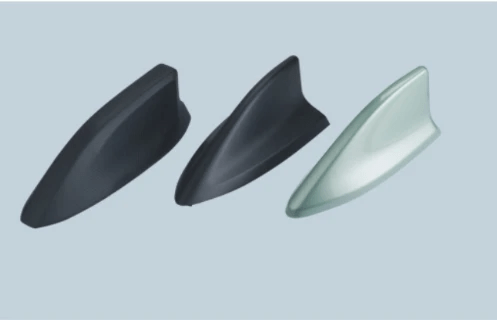

Cost Variations by Industry

Different industries have unique requirements that heavily influence the pricing of plastic molds. For example, the automotive industry may require highly specialized and intricate molds that can drive costs up significantly compared to simpler designs used in consumer goods. Additionally, industries such as medical devices or electronics often demand higher precision and quality standards, which further complicates how much does a plastic mold cost.

Moreover, market demand and competition within specific sectors can also affect pricing structures. For instance, if an industry is booming and requires a surge in production capacity, the urgency can lead to elevated costs for both molds and services associated with them. Thus, understanding these fluctuations is crucial for businesses looking to budget effectively.

Bulk Orders and Their Discounts

One of the most effective ways businesses can manage costs is through bulk orders of plastic molds. When companies place larger orders or commit to long-term contracts with manufacturers, they often benefit from significant discounts per unit—making it easier to understand how much do plastic molds cost in a more favorable light. This strategy not only reduces immediate expenses but also helps lock in prices against future increases.

However, while bulk orders can lead to savings on initial investments in mold production, it's essential for businesses to assess their actual needs carefully before committing financially. Overestimating demand could result in excess inventory or wasted resources if products don’t sell as anticipated. Therefore, weighing the pros and cons of bulk purchases becomes vital when considering long-term financial health.

Long-Term Investment vs. Short-Term Costs

When evaluating how much does plastic mold service cost over time versus initial expenditures is another critical aspect for businesses to consider. While high-quality molds may come with a hefty price tag upfront—often due to labor-intensive design processes or advanced materials—their durability can lead to lower maintenance costs down the road compared with cheaper alternatives that may wear out quickly or require frequent repairs.

Investing in quality molds typically results in improved efficiency during production runs—leading not only to better product output but also reduced waste during manufacturing processes; this ultimately contributes positively towards overall profitability over time. Thus understanding why plastic mold is expensive initially helps clarify its value proposition as a long-term investment rather than merely an immediate expense.

Ultimately, comprehending how much do injection molding costs varies based on these multifaceted considerations ensures that companies make informed decisions aligned with their operational goals and financial strategies.

How Much Does Plastic Mold Service Cost?

When considering the total expenses associated with plastic molds, it’s crucial to factor in the costs of maintenance and service. Understanding how much does plastic mold service cost can help businesses budget more effectively and ensure that their molds remain in optimal condition. This section breaks down the various components that contribute to the overall service costs.

Maintenance and Repair Costs

Maintenance and repair costs for plastic molds can vary significantly depending on factors like mold complexity and usage frequency. On average, businesses may spend anywhere from a few hundred to several thousand dollars annually on upkeep, especially if they require frequent repairs due to wear and tear. It's essential to recognize that investing in regular maintenance not only prolongs the life of your molds but also minimizes unexpected repair expenses—helping answer how much do plastic molds cost over time.

Onboarding Service Fees

When companies decide to partner with a new service provider for their plastic mold needs, onboarding fees often come into play. These fees cover initial assessments, training sessions, and setup costs required to get the services running smoothly. Depending on the provider, onboarding services can range from a few hundred dollars to thousands; thus, understanding how much does a plastic mold service cost upfront is vital for effective budgeting.

Comparing Service Providers

With numerous service providers available, comparing their offerings can save your business both time and money in the long run. Different companies may have varying pricing structures based on their expertise or additional services they provide beyond standard maintenance—making it critical to evaluate what each provider includes in their packages. By examining these differences closely, you can better understand why plastic mold is expensive while ensuring you select a provider that aligns with your budgetary constraints.

Why Plastic Mold Is Expensive?

When pondering the question of Why plastic mold is expensive?, several factors come into play, each contributing to the overall price tag attached to these essential manufacturing tools. The complexity of design, labor and expertise requirements, as well as production volume and cost efficiency are key elements that drive up costs. Understanding these components can help demystify the often hefty price associated with plastic molds.

Complexity of Design

The intricacy involved in mold design significantly affects how much does a plastic mold cost. A simple design may not break the bank, but when you start incorporating complex geometries or features like undercuts and intricate details, the costs can skyrocket. Additionally, custom designs tailored to specific products often require more time and resources to create, further inflating the final bill.

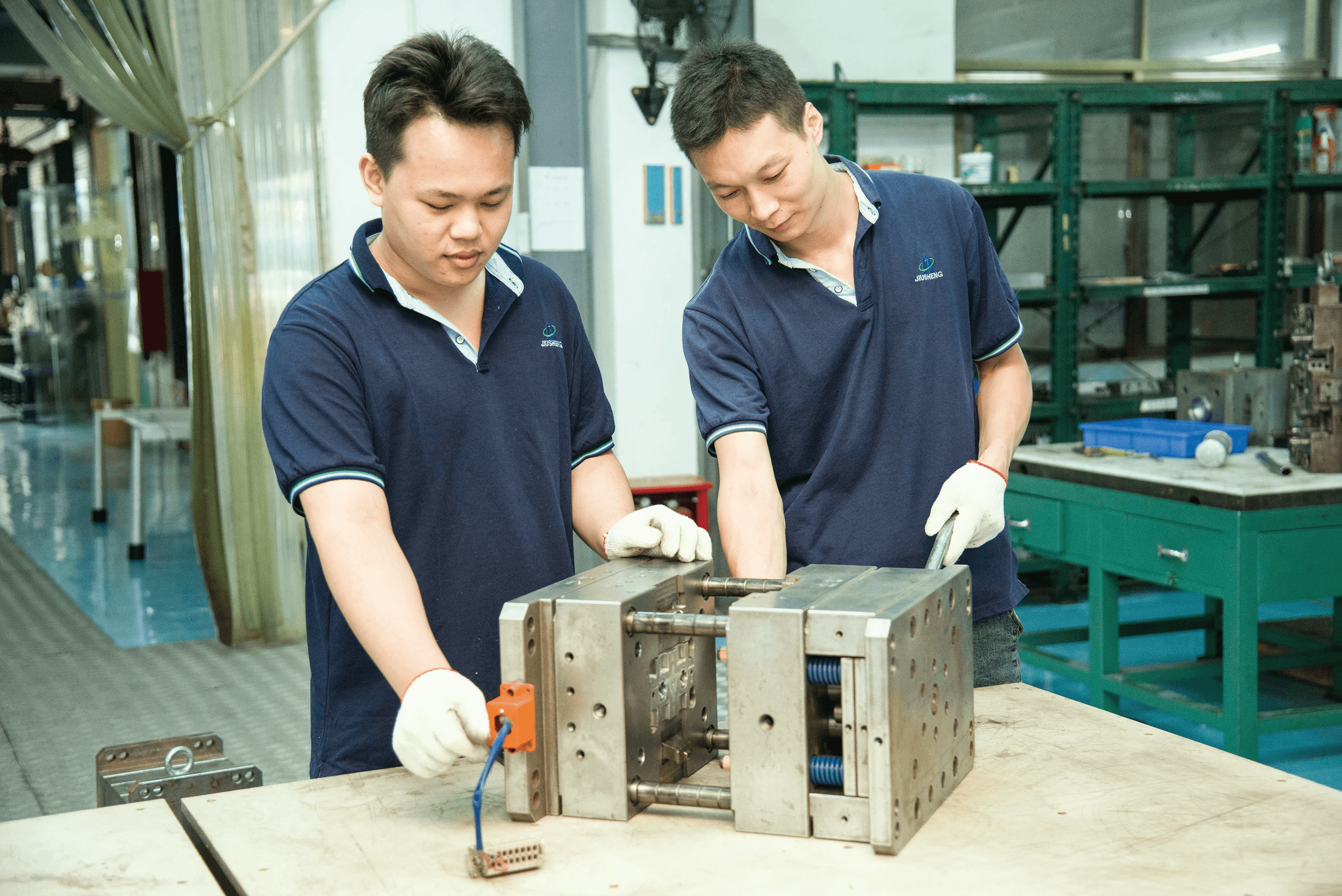

Labor and Expertise Requirements

Another major factor in determining how much do plastic molds cost is the labor involved in their creation. Skilled professionals who specialize in mold-making command higher wages due to their expertise and experience; this is especially true for intricate designs that require precision craftsmanship. The investment in skilled labor ensures that molds are built to last and perform efficiently during production runs, which ultimately affects how much does plastic mold service cost over time.

Production Volume and Cost Efficiency

Generally speaking, higher production volumes lead to lower per-unit costs due to economies of scale; however, initial setup costs for molds remain high regardless of volume. This means that businesses must weigh short-term costs against long-term savings when considering whether investing in high-quality molds will pay off down the line.

How Much Do Injection Molding Costs Vary?

When considering how much does a plastic mold cost, it’s essential to understand that injection molding costs can fluctuate significantly based on various factors. The complexity of the part being produced, the type of materials used, and the production volume all play critical roles in determining the final price. Additionally, geographical location and labor costs can further influence how much do plastic molds cost across different regions.

Cost Factors in Injection Molding

Several key elements contribute to how much does plastic mold service cost when it comes to injection molding. First, the initial cost of creating a mold is substantial; intricate designs require advanced technology and skilled labor to produce. Moreover, ongoing expenses such as maintenance and repairs can add up over time, leading businesses to ask why plastic mold is expensive in the first place.

Another factor influencing injection molding costs is material selection. Different plastics come with varying price tags, affecting not only initial costs but also long-term durability and performance. The choice between standard thermoplastics and specialty materials can drastically change how much do plastic molds cost overall.

Comparing Injection Molding to Other Methods

When evaluating how much do plastic molds cost through injection molding versus other manufacturing methods like blow molding or 3D printing, it's clear each has its advantages and drawbacks. While injection molding typically offers high precision and efficiency for large runs of identical parts, other methods may be more suitable for smaller batches or more complex designs at a lower upfront investment. This leads many businesses to weigh their options carefully when deciding which method aligns best with their budgetary constraints.

For instance, while 3D printing may have lower initial costs for prototypes or small runs, it often lacks the speed and scalability that injection molding provides for mass production needs. Thus, understanding these differences helps clarify why many companies still prefer traditional molds despite asking how much does a plastic mold cost initially.

Projecting Costs for Different Scales

Projecting costs for different scales of production is crucial when assessing how much does a plastic mold cost overall in your business strategy. For small-scale operations or startups venturing into product development, upfront investment might seem daunting; however, bulk orders through injection molding can lead to significant savings over time due to economies of scale. As production volumes increase, unit costs typically decrease—making it essential for businesses to consider long-term projections rather than just immediate expenses.

Furthermore, larger manufacturers often benefit from negotiated contracts with suppliers that reduce material costs significantly compared to smaller companies without such leverage. Therefore, understanding how much do plastic molds cost at various scales allows businesses to make informed decisions about their manufacturing processes while keeping an eye on future growth opportunities.

Conclusion

Navigating the world of plastic molds can feel like wandering through a maze, especially when it comes to understanding how much does a plastic mold cost. With various factors influencing pricing, from design complexity to material choices, it's crucial to make informed decisions. Ultimately, knowing how much do plastic molds cost can empower businesses to find the right balance between quality and affordability.

Insights on Choosing Affordable Molds

When considering how much does a plastic mold cost, it's vital to weigh your options carefully. Seek suppliers who offer competitive pricing without compromising on quality; this will save you from costly mistakes down the line. Remember that opting for cheaper molds might lead you to face issues later, which could increase your overall costs significantly.

Long-Term Savings with Quality Molds

Investing in high-quality molds may seem daunting at first due to their price tag—after all, why plastic mold is expensive? However, these initial expenses often translate into long-term savings by reducing maintenance and service costs over time. If you consider how much does plastic mold service cost in relation to the lifespan of a quality mold, you'll find that it pays off handsomely in the end.

Working with Experts like Baoyuan for Cost-Effectiveness

Collaborating with experienced professionals such as Baoyuan can help demystify questions like how much do injection molding costs vary across different projects. Their expertise not only provides insights into effective budgeting but also ensures you're getting the best value for your investment in plastic molds. By leveraging their knowledge and resources, businesses can navigate the complexities of mold pricing while maximizing efficiency and minimizing waste.