Introduction

When it comes to manufacturing automotive parts, injection moulding plays a crucial role in creating high-quality components. The process of injecting molten materials into a mold to produce plastic parts has revolutionized the automotive industry, offering durability and precision. Advanced techniques in injection moulding have further enhanced the production of plastic injection molded auto parts, ensuring top-notch quality and efficiency. This is where Baoyuan's expertise in injection moulding comes into play, providing innovative solutions for automotive manufacturers.

Understanding Injection Moulding Automotive Parts

The production of injection molding parts for automotive use involves intricate design and meticulous execution to meet industry standards. From interior components to exterior elements, such as bumpers and fenders, injection moulding plays a pivotal role in shaping these essential parts with precision and durability.

Injection moulding techniques have advanced significantly in recent years, allowing for more complex and intricate designs to be produced with greater efficiency and accuracy. This has enabled automotive manufacturers to create parts that are not only durable and precise but also aesthetically pleasing. With the use of advanced techniques, such as multi-material injection moulding and overmoulding, automotive parts can now be manufactured with a higher level of functionality and integration than ever before.

The Role of Advanced Techniques

Advanced techniques in injection moulding have revolutionized the manufacturing process by optimizing production efficiency and enhancing the quality of plastic injection molded parts. With technological advancements, automotive manufacturers can now produce complex designs and intricate details with ease, meeting the demands of modern vehicle designs.

Furthermore, advanced techniques in injection moulding have also led to significant cost savings for manufacturers. By reducing cycle times and minimizing material waste, these innovations have allowed companies to streamline their production processes and operate more efficiently. This has ultimately translated into lower production costs and more competitive pricing for consumers, making advanced injection moulding techniques a game-changer in the automotive industry.

Baoyuan: Expertise in Injection Moulding

Baoyuan stands out as an industry leader with its expertise in injection moulding for automotive parts. With a focus on innovation and precision, Baoyuan offers tailored solutions for producing high-quality plastic injection parts that meet the stringent requirements of the automotive sector.

With a dedicated team of experienced designers and engineers, Baoyuan excels in creating innovative and efficient tooling solutions for injection moulding. By utilizing the latest technology and industry best practices, Baoyuan ensures that the design and tooling process is optimized for maximum productivity and cost-effectiveness. This commitment to excellence sets Baoyuan apart as a trusted partner for automotive manufacturers seeking high-performance injection moulded parts.

Design and Tooling

Baoyuan's expertise in software design plays a crucial role in the production of injection moulding automotive parts. By utilizing advanced CAD/CAM software, Baoyuan is able to create intricate designs that meet the specific requirements of automotive manufacturers. This software expertise allows for precise customization and innovation in the design of injection molding parts, ensuring that each component meets the highest standards of quality and durability.

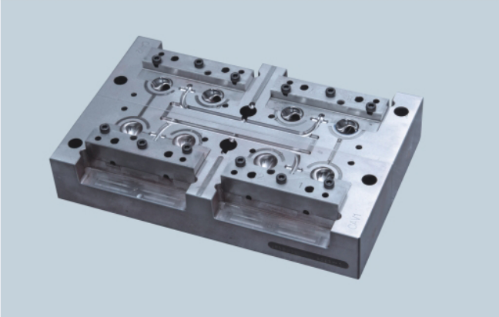

Precision tooling is a cornerstone of Baoyuan's approach to injection moulding automotive parts. With state-of-the-art CNC machining technology, Baoyuan is able to manufacture tooling with unparalleled accuracy and consistency. This precision ensures that each injection molded plastic part meets exact specifications, resulting in components that are reliable and long-lasting. The use of advanced tooling techniques also enables Baoyuan to optimize production processes, leading to increased efficiency and cost-effectiveness.

The advantages of advanced tooling techniques are evident in the exceptional quality of injection molding automotive parts produced by Baoyuan. By employing cutting-edge technologies such as hot runner systems and multi-cavity molds, Baoyuan is able to achieve higher levels of productivity without sacrificing quality. These advanced techniques also contribute to minimizing material waste and reducing cycle times, ultimately resulting in significant savings for automotive manufacturers.

Material Selection

High-Quality Materials for Injection Molded Plastic Parts

When it comes to injection moulding automotive parts, the quality of the materials used is crucial. Baoyuan understands the importance of using high-quality materials for injection molding parts, ensuring that the final products meet industry standards and withstand the demands of automotive applications.

Baoyuan's expertise in material procurement sets us apart from other injection molding companies. We have established strong relationships with reputable suppliers to ensure that we have access to the best quality materials for automotive parts. This allows us to consistently produce high-performing, durable products that meet the stringent requirements of the automotive industry.

Baoyuan's Expertise in Material Procurement

With years of experience in the industry, Baoyuan has established strong relationships with reputable suppliers, allowing them to procure top-notch materials for plastic injection molded parts. This expertise in material procurement ensures that only the best raw materials are used in the production process.

Furthermore, Baoyuan's extensive knowledge of the industry allows them to stay updated on the latest advancements in materials technology. This means they can recommend and source innovative materials that offer improved performance and durability for plastic injection molded parts. By staying ahead of the curve, Baoyuan ensures that their clients receive automotive parts made from cutting-edge materials that meet the highest standards of quality and longevity.

Importance of Material Durability in Automotive Parts

The durability of plastic injection parts is paramount in automotive applications, where components are subjected to various stresses and environmental factors. Baoyuan's commitment to using durable materials guarantees that their injection molded plastic auto parts will meet performance expectations and stand the test of time.

Baoyuan's focus on material durability not only ensures the longevity of their injection molded plastic auto parts but also contributes to overall vehicle safety. By using high-quality, durable materials, these automotive components are better equipped to withstand impact and harsh environmental conditions, providing added protection for drivers and passengers. This commitment to durability reflects Baoyuan's dedication to producing reliable and resilient automotive parts that prioritize both performance and safety.

Process Optimization

As a leader in injection moulding automotive parts, Baoyuan's expertise in injection molding is unparalleled. With years of experience and cutting-edge technology, the company has perfected the process to ensure top-quality plastic injection molded parts for automotive use.

Baoyuan's Injection Molding Expertise

Baoyuan's injection molding expertise is evident in their precision and attention to detail when crafting plastic injection parts for automotive applications. Their team of professionals understands the unique demands of the industry and consistently delivers exceptional results. In addition, Baoyuan utilizes advanced techniques for efficient production, ensuring that they can meet tight deadlines while maintaining high quality standards. This commitment to innovation and efficiency sets them apart in the competitive field of injection molding for automotive components.

Advanced Techniques for Efficient Production

Utilizing advanced techniques, Baoyuan ensures efficient production of injection molded plastic auto parts without compromising on quality. By streamlining their processes, they are able to meet high production demands while maintaining the integrity of each part. In addition to their streamlined processes, Baoyuan has implemented state-of-the-art robotic automation to further enhance efficiency and precision in production. This not only reduces the margin of error but also allows for consistent quality across all parts.

Enhancing Quality Control in Injection Molding Automotive Parts

Quality control is paramount in the production of injection molding automotive parts, and Baoyuan goes above and beyond to enhance this aspect of their process. Through rigorous testing and inspection protocols, they guarantee that every part meets the highest standards before it reaches the customer.

By investing in state-of-the-art machinery and employing skilled technicians, Baoyuan ensures that their injection molding process is optimized for efficiency and precision. This commitment to excellence sets them apart as a trusted partner for automotive manufacturers seeking high-quality plastic injection molded parts.

Customization and Innovation

Baoyuan's Proficiency in Custom Mold Design

Baoyuan's team of skilled engineers and designers excel in creating custom molds for injection moulding automotive parts. Their expertise allows them to craft molds that perfectly suit the specific requirements of each component, ensuring precision and efficiency in the production process. With a deep understanding of the automotive industry, Baoyuan's team is able to anticipate future trends and technological advancements, allowing them to design molds that are not only effective for current needs but also adaptable for future innovations. By staying ahead of the curve, Baoyuan ensures that their clients have access to cutting-edge mold designs that give them a competitive edge in the market.

Injection Molding for Unique Automotive Components

With Baoyuan's advanced injection molding techniques, unique and complex automotive components can be manufactured with ease. Their expertise in precision molding allows for the production of intricate interior parts that meet the highest standards of quality and design. Additionally, their ability to create durable exterior components ensures that vehicles are equipped with reliable and long-lasting parts that can withstand the demands of everyday use.

Importance of Innovation in Injection Moulding Processes

Innovation is at the core of Baoyuan's approach to injection moulding automotive parts. By constantly exploring new technologies and techniques, they stay ahead of industry trends, allowing them to offer cutting-edge solutions for their clients' unique requirements.

In addition to staying ahead of industry trends, Baoyuan's commitment to innovation in injection moulding processes also allows them to optimize production efficiency and reduce costs. By implementing new technologies and techniques, they are able to streamline their manufacturing processes and minimize waste, ultimately providing their clients with cost-effective solutions without compromising on quality. This focus on innovation not only benefits their clients but also positions Baoyuan as a leader in the automotive parts manufacturing industry.

Quality Assurance

When it comes to injection moulding automotive parts, Baoyuan's commitment to quality is unmatched. With advanced quality control measures in place, every plastic injection molded part undergoes rigorous inspection to ensure durability and reliability. From material selection to final inspection, Baoyuan's attention to detail guarantees the highest standard of automotive components.

Baoyuan's Advanced Quality Control Measures

Baoyuan employs cutting-edge technology and strict quality control protocols to maintain the highest standards in plastic injection molding parts. Every step of the production process is carefully monitored and tested, ensuring that each automotive part meets the stringent requirements for performance and durability.

Ensuring Durability of Plastic Injection Parts

With a focus on durability, Baoyuan uses only premium materials for injection molded plastic auto parts. These high-quality materials are selected for their strength and longevity, ensuring that every component can withstand the demands of automotive use without compromising on safety or performance.

Implementing Reliable Inspection Techniques

To guarantee the reliability of each injection molding automotive part, Baoyuan implements reliable inspection techniques throughout the production process. From initial tooling to final assembly, thorough inspections are carried out to identify any potential defects or imperfections, ensuring that only flawless components reach the market.

By maintaining a steadfast commitment to quality assurance and implementing advanced techniques in plastic injection molding, Baoyuan ensures that every automotive part meets the highest standards of durability and reliability in the industry.

Conclusion

Baoyuan's expertise in injection molding automotive parts is unmatched, offering precision and durability in every component. With advanced techniques and quality materials, they ensure the highest standards for plastic injection molded parts. Embracing innovation and customization, Baoyuan delivers unique solutions for automotive components that stand the test of time.

Advantages of Baoyuan's Injection Molding Expertise

Baoyuan's proficiency in injection molding automotive parts provides a competitive edge in the industry, delivering high-quality, precision-engineered components. Their advanced tooling techniques and material selection guarantee superior performance and longevity for every plastic injection part.

Ensuring Quality and Durability in Automotive Parts

By prioritizing material durability and employing stringent quality control measures, Baoyuan ensures that their injection molded plastic auto parts meet the highest standards for strength and resilience. This commitment to excellence guarantees reliable performance for automotive applications.

Embracing Advanced Techniques for Injection Moulding

Baoyuan's dedication to embracing advanced techniques sets them apart as leaders in injection moulding automotive parts manufacturing. From custom mold design to efficient production processes, they consistently innovate to deliver cutting-edge solutions for the automotive industry.