Introduction

When it comes to durable and versatile materials for various applications, acrylic and polycarbonate stand out as popular choices. Baoyuan has established itself as a leader in the production and distribution of high-quality acrylic and polycarbonate materials, with a deep understanding of their unique properties and applications. In this article, we will explore the differences between acrylic and polycarbonate, shedding light on their respective strengths and best uses.

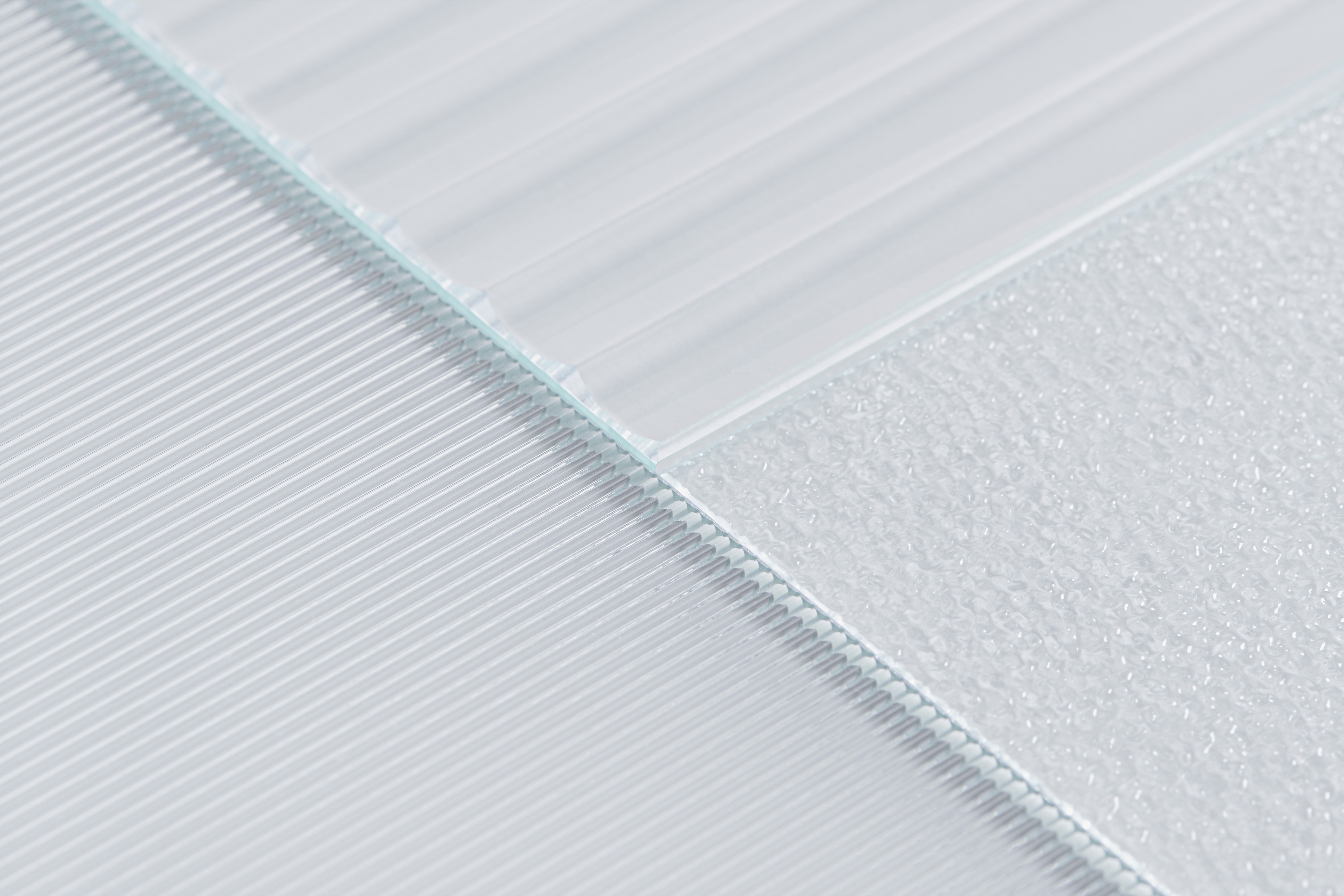

Understanding Acrylic and Polycarbonate

Acrylic, also known as PMMA, is a transparent thermoplastic that offers excellent optical clarity and weather resistance. On the other hand, polycarbonate is a tough thermoplastic known for its impact resistance and high heat resistance. Both materials are widely used in various industries due to their unique properties.

Baoyuan’s expertise in acrylic and polycarbonate materials

Baoyuan has built a solid reputation for its expertise in the production and distribution of top-notch acrylic and polycarbonate materials. With a focus on quality control and innovation, Baoyuan ensures that its products meet the highest standards for performance and durability.

Exploring the differences between acrylic and polycarbonate

While both acrylic and polycarbonate offer exceptional qualities, they differ in terms of impact resistance, UV resistance, optical clarity, scratch resistance, and more. Understanding these differences is crucial for making informed decisions when choosing between these two materials for specific applications.

Material Composition

When it comes to the chemical composition, acrylic is made from polymethyl methacrylate, while polycarbonate is composed of bisphenol A and phosgene. Acrylic is known for its superior impact resistance compared to polycarbonate, making it a popular choice for applications where durability is essential. On the other hand, polycarbonate offers excellent UV resistance, making it suitable for outdoor use.

Chemical composition of acrylic and polycarbonate

Acrylic is primarily composed of polymethyl methacrylate (PMMA), a transparent thermoplastic known for its exceptional optical clarity and weather resistance. On the other hand, polycarbonate is made from bisphenol A and phosgene, resulting in a highly durable and impact-resistant material.

Impact resistance of acrylic vs polycarbonate

Acrylic boasts impressive impact resistance, making it suitable for use in applications where durability is crucial. However, polycarbonate surpasses acrylic in terms of impact resistance, making it an ideal choice for applications that require superior strength and toughness.

Acrylic's impact resistance makes it a top choice for applications where durability is key. Its ability to withstand impact makes it perfect for use in items such as display cases, signage, and protective barriers. However, when it comes to applications that demand superior strength and toughness, polycarbonate outshines acrylic with its unmatched impact resistance.

UV resistance in acrylic and polycarbonate

While both materials offer some level of UV resistance, polycarbonate excels in this area due to its ability to withstand prolonged exposure to sunlight without yellowing or deteriorating. This makes it an excellent choice for outdoor applications such as signage and protective barriers.

Additionally, polycarbonate offers superior impact resistance compared to acrylic, making it an ideal choice for outdoor applications where durability is crucial. Its ability to withstand high-impact forces without shattering or cracking makes it a reliable option for protective barriers in high-traffic areas. This added strength also provides peace of mind in areas prone to extreme weather conditions, ensuring that the material will hold up under pressure.

Optical Clarity

Transparency and light transmission in acrylic and polycarbonate

When it comes to transparency and light transmission, both acrylic and polycarbonate offer excellent optical clarity. Acrylic has a slightly higher light transmission rate of 92% compared to polycarbonate's 90%. However, polycarbonate lenses are known for their exceptional impact resistance, making them a popular choice for safety glasses and sports eyewear.

Scratch resistance of acrylic vs polycarbonate

In terms of scratch resistance, polycarbonate outperforms acrylic due to its hard-coated surface that provides superior durability against scratches. This makes polycarbonate lenses ideal for high-impact applications where lens durability is crucial.

In addition to its superior scratch resistance, polycarbonate lenses also offer excellent impact resistance, making them an ideal choice for safety eyewear in high-risk environments. The hard-coated surface not only protects against scratches but also provides a layer of defense against impact and potential damage, ensuring the longevity of the lenses in demanding conditions. This makes polycarbonate lenses a top choice for individuals working in construction, manufacturing, or any other industry where eye protection is paramount.

Optical quality of Baoyuan's acrylic and polycarbonate products

Baoyuan takes pride in the optical quality of its acrylic and polycarbonate products, ensuring that they meet the highest standards for clarity and precision. Whether it's for automotive lighting lenses or display panels, Baoyuan's expertise in injection molded polycarbonate guarantees exceptional optical performance in all applications.

Baoyuan's commitment to optical quality extends beyond just clarity and precision. Their acrylic and polycarbonate products are also engineered to withstand harsh environmental conditions, ensuring long-lasting durability without compromising on visual performance. This makes Baoyuan a top choice for manufacturers looking for reliable materials that can maintain exceptional optical quality in demanding applications.

Applications

When it comes to applications, both acrylic and polycarbonate materials have a wide range of uses. Acrylic is commonly used for signage, display cases, and protective barriers due to its clarity and scratch resistance. On the other hand, polycarbonate is often used in eyewear, safety helmets, and automotive components because of its impact resistance and durability.

Common uses for acrylic and polycarbonate materials

Acrylic is frequently used in architectural glazing, aquariums, and lighting fixtures due to its optical clarity and weather resistance. Polycarbonate lenses are also popular in eyewear and safety goggles because of their impact resistance and lightweight nature. Both materials are versatile enough to be used in various industries for different purposes.

In addition to architectural glazing, aquariums, and lighting fixtures, acrylic is also commonly used in retail displays and signage due to its lightweight nature and ability to be easily shaped and colored. Its durability and resistance to yellowing make it a popular choice for outdoor signs and displays, allowing businesses to create eye-catching visuals that can withstand various weather conditions. Additionally, acrylic is often used in art installations and sculptures due to its versatility and ability to enhance the visual impact of the artwork.

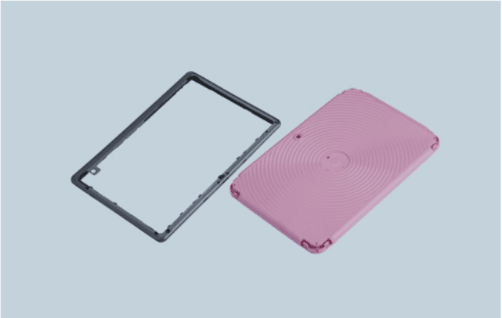

Baoyuan's expertise in injection molded polycarbonate

Baoyuan has extensive experience in injection molding polycarbonate, particularly for producing high-quality lenses for eyewear and safety equipment. Their expertise lies in creating precise molds that result in durable yet lightweight products that meet industry standards for impact resistance.

Benefits of using acrylic or polycarbonate in different applications

The choice between acrylic or polycarbonate depends on the specific application’s requirements. Acrylic offers exceptional optical clarity and scratch resistance, making it ideal for display cases or architectural glazing where aesthetics are crucial. Meanwhile, polycarbonate’s superior impact resistance makes it the preferred choice for safety equipment such as helmets or goggles where protection is paramount.

Manufacturing Process

When it comes to the injection molding process for polycarbonate vs abs, there are significant differences. Polycarbonate is known for its high impact resistance and heat resistance, making it ideal for applications such as safety goggles and automotive components. On the other hand, ABS (acrylonitrile butadiene styrene) is a thermoplastic polymer that offers good impact resistance and toughness, making it suitable for items like protective gear and toys.

Injection molding process for polycarbonate vs abs

The injection molding process for polycarbonate involves melting the material and injecting it into a mold under high pressure, allowing it to cool and harden into the desired shape. This process requires precision and expertise to ensure the final product meets quality standards. In contrast, ABS has similar injection molding requirements but may not offer the same level of impact resistance as polycarbonate.

Baoyuan's advanced software for mold design and injection molding

Baoyuan utilizes advanced software for mold design and injection molding to ensure precise and efficient production of plastic products. With cutting-edge technology and experienced engineers, Baoyuan can create custom molds tailored to specific customer needs, resulting in high-quality acrylic or polycarbonate products that meet industry standards.

Quality assurance in Baoyuan's production of plastic products

Quality assurance is a top priority at Baoyuan, with rigorous testing procedures in place to guarantee the durability, performance, and safety of their plastic products. Each step of the manufacturing process is carefully monitored to maintain consistency and excellence in every acrylic or polycarbonate item produced.

In addition to stringent testing procedures, Baoyuan also invests in state-of-the-art technology and equipment to ensure the highest quality standards are met. This includes the use of advanced injection molding processes and cutting-edge materials to create durable and long-lasting plastic products. By staying at the forefront of industry advancements, Baoyuan can consistently deliver innovative and reliable solutions to meet the evolving needs of their customers.

Environmental Impact

Sustainability of acrylic and polycarbonate materials

When considering the sustainability of acrylic or polycarbonate materials, it's important to note that both are highly durable and long-lasting, reducing the need for frequent replacements. Polycarbonate lenses, for example, are known for their impact resistance and can withstand harsh conditions, making them a sustainable choice for eyewear and other applications. Additionally, both acrylic and polycarbonate can be recycled, further contributing to their eco-friendly nature.

Baoyuan's commitment to environmentally friendly production

Baoyuan is dedicated to environmentally friendly production practices, ensuring that the manufacturing process for acrylic and polycarbonate materials minimizes waste and energy consumption. By utilizing advanced technology and sustainable sourcing methods, Baoyuan upholds its commitment to reducing its environmental footprint while producing high-quality plastic products.

Comparing the environmental impact of acrylic and polycarbonate

When comparing the environmental impact of acrylic and polycarbonate, it's essential to consider factors such as energy consumption during production, recyclability, and overall durability. Both materials have their own set of environmental benefits, with acrylic being easily recyclable and polycarbonate being highly durable with a longer lifespan. By evaluating these factors, businesses can make informed decisions on which material aligns best with their sustainability goals.

Conclusion

When it comes to making the right choice between acrylic or polycarbonate, it's important to consider factors such as impact resistance, UV resistance, and optical clarity. Baoyuan's expertise in the production and quality assurance of plastic products ensures that you'll receive high-quality materials for your specific application needs.

Making the right choice between acrylic or polycarbonate

Whether you choose acrylic or polycarbonate will depend on the specific requirements of your project. Acrylic is known for its exceptional optical clarity and scratch resistance, making it a great choice for applications such as signage and display cases. On the other hand, polycarbonate is favored for its superior impact resistance and is commonly used in applications that require a high level of durability, such as safety goggles and bulletproof windows.

When considering the right material for your project, it's important to take into account the specific needs and demands of the application. Acrylic's exceptional optical clarity and scratch resistance make it a top choice for projects that require high visibility and aesthetics, such as signage and display cases. On the other hand, if your project requires superior impact resistance and durability, polycarbonate is the way to go. Its ability to withstand high-impact makes it ideal for applications like safety goggles and bulletproof windows, where strength and resilience are paramount.

Baoyuan's role in the production and quality assurance of plastic products

Baoyuan's commitment to excellence in the production and quality assurance of plastic products sets them apart from other manufacturers. Their expertise in injection molded polycarbonate allows them to create complex shapes with precision, ensuring that their products meet the highest standards of performance and reliability. Additionally, Baoyuan's dedication to research and development enables them to stay at the forefront of innovation in plastic manufacturing, constantly seeking new ways to improve their materials and processes. This commitment to staying ahead of industry trends ensures that customers receive cutting-edge plastic products that outperform the competition.

Exploring the benefits of acrylic and polycarbonate materials

Both acrylic and polycarbonate offer unique benefits that make them suitable for a wide range of applications. Acrylic's exceptional optical clarity and scratch resistance make it ideal for use in retail displays and architectural glazing, while polycarbonate's unmatched impact resistance makes it a top choice for automotive components and electronic enclosures.

With Baoyuan's expertise in both acrylic and polycarbonate materials, you can be confident that you're getting top-quality products that are tailored to your specific needs. Whether you're looking for injection molded polycarbonate lenses or polypropylene injection molding solutions, Baoyuan has the knowledge and experience to deliver outstanding results every time.