Introduction

Welcome to the world of polycarbonate injection molding, where innovation meets quality. As a leading process in plastic molding, injection molding offers unparalleled benefits for various industries. At Baoyuan, our team's expertise in polycarbonate injection molding ensures superior results and unmatched precision.

Understanding Polycarbonate Injection Molding

Polycarbonate injection molding is a highly versatile process that involves injecting molten polycarbonate material into a mold cavity to create intricate shapes and designs. This method is widely used for producing high-quality parts and components with exceptional strength and durability.

Benefits of Polycarbonate Injection Molding

Polycarbonate injection molding offers a powerful combination of speed, precision, and versatility for manufacturing high-quality plastic parts. Here are some of its key benefits:

- Fast Production Cycles: Compared to other manufacturing methods, polycarbonate injection molding boasts rapid cycle times, allowing for quicker production and turnaround.

- Cost-Effectiveness: This process is efficient in material usage and offers high production rates, leading to cost-competitive parts, especially for high-volume runs.

- Design Flexibility and Tight Tolerances: Polycarbonate injection molding can produce complex geometries with precise dimensions, enabling intricate designs and reliable part functionality.

- Wide Material Compatibility: This method works with various materials, catering to the specific needs of different applications and industries.

- Superior Strength and Clarity: Polycarbonate is known for its exceptional impact resistance and optical transparency. This combination makes it ideal for parts requiring both durability and visibility.

- Lightweight Construction: Polycarbonate parts are solid yet lightweight, reducing weight in the final product and potentially improving efficiency.

Polycarbonate injection molding is a valuable manufacturing technique for creating high-performance plastic parts across diverse industries. Its speed, precision, material versatility, and polycarbonate's inherent properties make it a compelling choice for a wide range of applications.

Baoyuan Team Expertise in Polycarbonate Injection Molding

At Baoyuan, we take pride in our team's extensive expertise in polycarbonate injection molding. With years of experience and a commitment to excellence, our professionals are dedicated to delivering top-notch results that exceed our clients' expectations.

Our team's expertise in polycarbonate injection molding enables us to tackle even the most complex projects confidently and precisely. We understand the nuances of working with polycarbonate material and have developed innovative techniques to ensure optimal results. From initial design concepts to final production, our team is committed to delivering superior quality and efficiency every step of the way.

Now, let's explore the basics of polycarbonate injection molding and its key features and advantages!

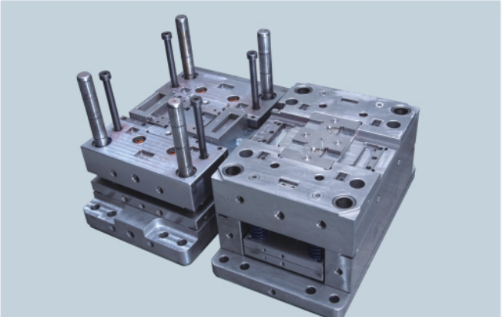

The Basics of Polycarbonate Injection Molding

Polycarbonate injection molding is a process in which polycarbonate, a highly durable and impact-resistant thermoplastic, is melted and injected into a mold to create various plastic parts and components. This method allows for producing complex shapes with high precision and repeatability, making it ideal for a wide range of applications.

What is Polycarbonate Injection Molding?

Polycarbonate injection molding involves heating polycarbonate resin pellets to their melting point before injecting the molten material into a mold cavity under high pressure. Once the material cools and solidifies, the mold is opened to reveal the finished part. This process can produce anything from small, intricate components to large, structural parts with exceptional detail and accuracy.

Polycarbonate injection molding offers a high level of design flexibility, allowing for the creation of complex shapes and intricate details that would be difficult or impossible to achieve with other manufacturing methods. This makes it ideal for producing parts with unique features or specific functional requirements. In addition, polycarbonate is known for its exceptional impact resistance and transparency, making it suitable for a wide range of applications in industries such as automotive, electronics, and consumer goods.

Key Features of Polycarbonate Injection Molding

Polycarbonate injection molding is a versatile and cost-effective manufacturing process for producing high-quality parts. Here are some of its key benefits:

- Exceptional Dimensional Stability and High Impact Resistance: Polycarbonate parts retain shape and withstand significant force without breaking, making them ideal for demanding applications.

- Superior Optical Clarity: Polycarbonate offers excellent transparency, rivaling glass in some cases. This makes it a popular choice for lenses, windows, and displays.

- Excellent Heat Resistance and Chemical Resistance: Polycarbonate parts can endure high temperatures and exposure to harsh chemicals without degrading, ensuring long-lasting performance.

- High Precision and Accuracy for Complex Parts: Polycarbonate injection molding allows for the creation of intricate designs with tight tolerances, crucial for industries like electronics, automotive, and medical devices.

- Mass Production and Cost-Effectiveness: This process excels at high-volume production, making it cost-effective for manufacturing many parts.

Polycarbonate injection molding's combination of durability, clarity, precision, and efficient production make it a valuable tool for manufacturers across various industries.

How Baoyuan Ensures High-Quality Results

Baoyuan's expertise in polycarbonate injection molding lies in its state-of-the-art equipment, rigorous quality control processes, and experienced team of engineers and technicians. Using advanced mold design software and precision molding techniques, Baoyuan ensures that each polycarbonate injection molded part meets or exceeds the highest industry standards for quality and performance.

Furthermore, Baoyuan's commitment to quality extends beyond the manufacturing process. The company conducts thorough testing and inspection of each polycarbonate injection-molded part to ensure it meets all specifications and requirements. This dedication to quality control helps minimize defects and ensures that customers receive products that are reliable and consistent in performance.

Advantages of Polycarbonate Injection Molding

Polycarbonate injection molding offers numerous advantages, making it a popular choice for various applications. Its exceptional impact resistance and high heat tolerance make it ideal for products that require durability and reliability. Polycarbonate's transparency and optical clarity also allow for the creation of visually appealing products that meet stringent quality standards.

Strengths of Injection Molding with Polycarbonate

One of the key strengths of polycarbonate injection molding is its ability to produce parts with complex geometries and intricate details, all while maintaining superior strength and structural integrity. This makes it an excellent choice for applications where precision and performance are paramount, such as automotive components, electronic enclosures, and medical devices.

Versatility and Design Flexibility

Polycarbonate injection molding offers unparalleled design flexibility, allowing for creating parts with varying thicknesses, textures, and finishes. This versatility enables designers to bring their creative visions to life while ensuring that the final product meets the specific requirements of each application. Polycarbonate injection molding can accommodate many design needs, from sleek, modern consumer electronics to rugged industrial equipment.

Furthermore, polycarbonate injection molding allows for integrating multiple components into a single part, reducing assembly time and costs. This feature is particularly beneficial for complex designs that require intricate geometries and functional elements. Manufacturers can streamline production processes and improve overall product quality by consolidating parts into a single mold. This capability sets polycarbonate injection molding apart as a cost-effective and efficient solution for various applications.

The Baoyuan Difference in Injection Molding Applications

Regarding injection molding companies, Baoyuan stands out for its expertise in working with polycarbonate and other injection moldable plastics. With state-of-the-art facilities and a team of experienced professionals, Baoyuan can handle even the most challenging projects with precision and efficiency. By partnering with Baoyuan, clients can expect exceptional results that meet their exact specifications and exceed their expectations. Additionally, Baoyuan prides itself on its commitment to sustainability, using eco-friendly materials and processes to minimize environmental impact without sacrificing quality. This dedication to responsible manufacturing sets Baoyuan apart in the industry, providing clients with peace of mind knowing their products are produced ethically.

Best Practices for High-Quality Results

Quality Control in Polycarbonate Injection Molding

Quality control is crucial for ensuring the integrity of the final products in polycarbonate injection molding. Baoyuan employs advanced quality control measures throughout the injection molding process, from material selection to final inspection. This meticulous attention to detail helps guarantee that every part meets the highest quality and performance standards.

Design Considerations for Successful Molding

Successful polycarbonate injection molding requires careful consideration of design elements such as wall thickness, gate location, and part geometry. Baoyuan's team of experienced engineers works closely with clients to optimize designs for manufacturability, ensuring that each moldable plastic component is produced with precision and efficiency.

Baoyuan's Approach to Achieving Consistent Quality

Baoyuan's commitment to achieving consistent quality in plastic injection molding is evident in its rigorous adherence to industry best practices and standards. From utilizing state-of-the-art equipment to employing highly skilled technicians, Baoyuan focuses on excellence at every stage of the injection molding process. This dedication results in reliable, high-quality outcomes for every project.

In addition to focusing on equipment and personnel, Baoyuan prioritizes continuous improvement and innovation to achieve consistent quality. By staying abreast of the latest advancements in injection molding technology and techniques, Baoyuan ensures they are always at the forefront of industry developments. This proactive stance allows them to adapt quickly to changes in customer requirements and market demands, further enhancing the quality of their output.

Choosing the Right Injection Molding Partner

When selecting an injection molding company for your project, it's crucial to consider key factors such as expertise, quality, and reliability. Look for a partner with a proven track record in polycarbonate injection molding, as this will ensure that your project is in capable hands.

Key Factors in Selecting an Injection Molding Company

One of the most important factors to consider when choosing an injection molding partner is their experience and expertise in working with moldable plastics like polycarbonate. A company specializing in plastic injection molding will have the knowledge and skills to produce high-quality results consistently. Additionally, assessing their capabilities in handling complex designs and meeting specific project requirements is essential.

Another crucial factor is the injection molding company's quality control processes. A reputable company will have strict quality control measures to ensure that each product meets the required specifications and standards. This includes thorough testing and inspection procedures to identify defects or imperfections before the final products are delivered. By choosing a company with robust quality control processes, you can have confidence in the reliability and consistency of their output.

Baoyuan's Track Record of Excellence

Baoyuan has established itself as a leader in plastic injection molding, with a strong reputation for delivering exceptional results. With extensive experience in polycarbonate injection molding, Baoyuan has successfully executed numerous projects across various industries, earning clients' trust worldwide. Their commitment to quality and innovation sets them apart as a top choice for injection molding solutions.

Baoyuan's track record of excellence is further solidified by its state-of-the-art facilities and cutting-edge technology. Its modern equipment and advanced manufacturing processes enable it to consistently deliver high-quality, precision-engineered plastic components. This commitment to staying at the forefront of industry advancements ensures that Baoyuan remains a trusted partner for clients seeking innovative solutions in plastic injection molding.

The Value of Experience and Expertise in Plastic Injection Molding

Don't navigate the complexities of plastic injection molding alone. Partnering with an experienced team like Baoyuan offers a multitude of benefits:

- Proactive Problem-Solving: Baoyuan's expertise allows them to identify potential issues early and implement solutions before they become problems. This saves you time and resources down the line.

- Optimized Processes: Their experience allows them to streamline the manufacturing process efficiently, ensuring your project is completed on time and within budget.

- Superior Outcomes: Baoyuan's deep understanding of polycarbonate injection molding ensures your project receives the meticulous attention to detail it deserves, guaranteeing high-quality results.

By choosing Baoyuan as your partner, you can achieve peace of mind knowing your project is in capable hands and poised for success.

Elevate Your Projects with Quality Injection Molding

Polycarbonate injection molding offers unparalleled strength and design flexibility for your projects. With Baoyuan's expertise in plastic injection molding, you can ensure success with high-quality results. Partnering with Baoyuan means elevating your projects with superior injection molding capabilities.

Ensuring Success with Polycarbonate Injection Molding

Choosing polycarbonate injection molding ensures the durability and reliability of your products. With Baoyuan's advanced techniques and quality control, you can trust that your molded parts will meet the highest standards for performance and longevity. Our team of experienced engineers is also dedicated to finding innovative solutions to any challenges that may arise during the molding process, ensuring a smooth and efficient production cycle. Moreover, our commitment to sustainability means that we prioritize environmentally friendly practices in our manufacturing processes, giving you peace of mind knowing that your products are durable and eco-friendly.

Partnering with Baoyuan for Superior Results

Baoyuan's track record of excellence in plastic injection molding companies speaks for itself. With a commitment to precision and innovation, Baoyuan delivers superior results that exceed expectations, making it the ideal partner for all your injection-moldable plastics needs.

By choosing Baoyuan as your plastic molding partner, you are taking your projects to the next level. The versatility and expertise in mold plastic injection ensure that every aspect of your design is brought to life with exceptional quality and attention to detail.