Introduction

In the fast-paced world of automotive manufacturing, plastic injection molding plays a crucial role in producing high-quality, durable components. This innovative technology offers numerous advantages, including cost-effectiveness, design flexibility, and production efficiency. Baoyuan has established itself as a leader in automotive injection molding, with a proven track record of expertise and excellence.

Importance of Automotive Plastic Injection Molding

The importance of automotive plastic injection molding cannot be overstated. It enables the production of intricate parts with precision and consistency, meeting the rigorous demands of the automotive industry for quality and durability.

Advantages of Plastic Injection Molding Technology

Plastic injection molding technology offers a wide range of advantages, such as reduced production costs, faster production cycles, and the ability to create complex shapes and designs. This makes it an ideal choice for manufacturing automotive components.

Furthermore, plastic injection molding technology allows for the production of lightweight yet durable automotive components, contributing to improved fuel efficiency and overall vehicle performance. In addition, the process enables manufacturers to incorporate multiple materials into a single part, reducing the need for assembly and minimizing potential points of failure. This versatility and efficiency make plastic injection molding a cost-effective solution for producing high-quality automotive parts at scale.

Baoyuan's Expertise in Automotive Injection Molding

As one of the leading automotive injection molding companies, Baoyuan has honed its expertise in delivering top-notch products through an efficient injection molding process. With a focus on quality and innovation, Baoyuan is dedicated to meeting the unique needs of its clients in the automotive industry.

With state-of-the-art technology and a team of experienced engineers, Baoyuan is able to streamline the injection molding process, resulting in cost-effective solutions for its automotive clients. By optimizing production efficiency and minimizing waste, Baoyuan is able to offer competitive pricing without compromising on quality. This commitment to cost-effectiveness has made Baoyuan a trusted partner for automotive companies looking to maximize their budget without sacrificing the integrity of their products.

Cost-Effectiveness

When it comes to plastic injection molding automotive, cost-effectiveness is a key consideration. Automotive Injection Molding offers reduced production costs by minimizing material waste and optimizing cycle times. Baoyuan excels in this area with an efficient Injection molding process that maximizes productivity while keeping costs down.

Reduced production costs with Automotive Injection Molding

Automotive injection molding companies benefit from reduced production costs due to the precise nature of Plastic Injection Molding Technology. With minimal material wastage and faster production cycles, the overall cost of manufacturing automotive parts is significantly lowered. This makes Automotive Injection Molding a cost-effective solution for producing high-quality plastic components.

Baoyuan's efficient Injection molding process

Baoyuan's expertise in the injection molding process ensures efficiency at every stage of production. From material selection to mold design and final product assembly, our streamlined approach minimizes downtime and maximizes output, resulting in significant cost savings for our clients.

Furthermore, our commitment to sustainability is reflected in our injection molding process. We prioritize the use of eco-friendly materials and implement waste reduction strategies to minimize our environmental impact. By integrating green practices into our production process, we not only contribute to a healthier planet but also enhance the overall value of our products for environmentally conscious consumers.

By focusing on cost-effectiveness through reduced production costs and an efficient injection molding process, Baoyuan continues to lead the way in providing high-quality automotive plastic components at competitive prices within the industry.

Design Flexibility

When it comes to Automotive Injection Molding, design flexibility is crucial. With the use of Plastic Injection Molding Technology, automotive parts can be customized to meet specific requirements. Baoyuan excels in offering a wide range of customization options for automotive injection molding, providing clients with the ability to create unique and innovative designs that set their products apart in the market.

Customization options in Automotive Injection Molding

Baoyuan's expertise in plastic injection molding automotive allows for a myriad of customization options, from varying shapes and sizes to different colors and textures. This level of flexibility enables automotive manufacturers to create parts that are not only functional but also visually appealing, enhancing the overall aesthetic of their vehicles. With Baoyuan's advanced technology and skilled team, clients can bring their design ideas to life with ease. Moreover, Baoyuan's team is well-versed in the latest trends and innovations in automotive design, ensuring that their customized parts are not only aesthetically pleasing but also meet the highest standards of performance and durability.

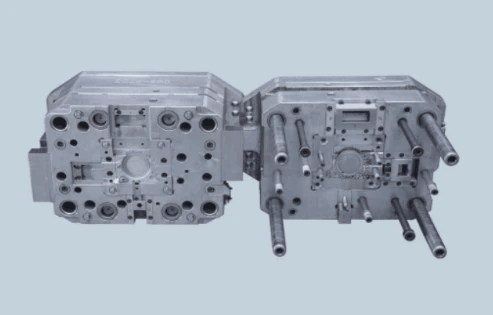

Baoyuan's skilled team for mold design and production

The key to successful Automotive Injection Molding lies in effective mold design and production. Baoyuan boasts a highly skilled team that specializes in creating molds tailored to each client's specifications. From initial concept to final product, Baoyuan's team ensures that every detail is meticulously considered, resulting in high-quality molds that produce top-notch automotive parts. Their expertise in mold design and production sets them apart as leaders in the plastic injection molding industry.

Additionally, Baoyuan's team is dedicated to ensuring that the molds they produce are not only of the highest quality but also durable. By using advanced materials and innovative techniques, they are able to create molds that can withstand the rigors of automotive production. This commitment to durability means that clients can rely on Baoyuan's molds for long-lasting performance, reducing the need for frequent replacements and maintenance.

Quality and Durability

When it comes to high-quality Automotive Injection Molding products, Baoyuan is the go-to choice for automotive manufacturers. Our state-of-the-art Plastic Injection Molding Technology ensures that each product meets the highest standards of quality and durability. From interior components to exterior parts, our Automotive Injection Molding process guarantees top-notch results that exceed industry expectations.

High-quality Automotive Injection Molding products

At Baoyuan, we take pride in delivering top-notch Automotive Injection Molding products that are not only durable but also reliable. Our team of experts ensures that every single component meets stringent quality control measures, providing automotive companies with peace of mind knowing they are receiving the best-in-class plastic injection molded products for their vehicles.

Our commitment to excellence extends beyond just the quality of our products. We also prioritize efficiency and timely delivery, ensuring that automotive companies receive their injection molded components on schedule. By streamlining our production processes and investing in cutting-edge technology, we are able to meet tight deadlines without compromising on the quality of our products. This dedication to both quality and reliability has earned us a reputation as a trusted partner in the automotive industry.

Baoyuan's proficiency in quality assurance

Baoyuan has established itself as a leader in quality assurance within the Automotive injection molding industry. Our commitment to excellence is evident in our rigorous testing procedures and meticulous attention to detail throughout the entire Plastic Injection Molding process. With Baoyuan, automotive manufacturers can trust that their products will withstand the test of time and deliver exceptional performance on the road.

Furthermore, Baoyuan's proficiency in quality assurance extends to our production efficiency. Our state-of-the-art manufacturing facilities and cutting-edge technology allow us to streamline the injection molding process, reducing lead times and increasing overall productivity. This means automotive manufacturers can rely on Baoyuan not only for exceptional quality but also for timely delivery of their components, helping them meet their production deadlines and stay ahead in the competitive market.

Production Efficiency

In the realm of automotive plastic injection molding, production efficiency is paramount. With the use of Plastic Injection Molding Technology, companies can significantly reduce production time and costs. Baoyuan's streamlined Injection molding process ensures that each product is manufactured with maximum efficiency, meeting the demands of Automotive Injection Molding companies for high-volume production.

Enhanced production efficiency with Plastic Injection Molding

The utilization of Plastic Injection Molding Technology in automotive manufacturing has revolutionized production processes, allowing for the creation of complex and intricate parts at a rapid pace. This technology enables Automotive Injection Molding companies to produce large quantities of components with minimal waste, ultimately leading to enhanced production efficiency and cost savings.

The use of Plastic Injection Molding Technology has not only improved production efficiency but also enhanced the quality of automotive components. With precise control over the molding process, companies can ensure that each part meets the highest standards, reducing the need for rework or quality control measures. This level of consistency and reliability ultimately contributes to overall cost savings and customer satisfaction.

Baoyuan's expertise in single-color and double-color plastic products

Baoyuan's expertise in single-color and double-color plastic products not only enhances production efficiency for automotive applications, but also sets the company apart as a leader in the industry. By leveraging advanced mold design techniques, Baoyuan's skilled team is able to create custom components with unmatched precision and speed, meeting the diverse needs of automotive injection molding companies. This commitment to excellence positions Baoyuan as a go-to partner for those seeking high-quality, multi-colored plastic parts that meet stringent industry standards.

Industry Leadership

Baoyuan has solidified its position as a leading Automotive Injection Molding company through its commitment to innovation and excellence in the field of plastic injection molding automotive. With a focus on advanced Plastic Injection Molding Technology, Baoyuan continues to set industry standards for Automotive Injection Molding, offering unparalleled expertise and cutting-edge solutions that meet the demands of modern automotive manufacturers.

Baoyuan's position as a leading Automotive Injection Molding company

As one of the top automotive injection molding companies, Baoyuan has continuously demonstrated its leadership in the industry by delivering high-quality products and exceptional customer service. With a strong emphasis on precision and efficiency in the Injection molding process, Baoyuan has earned a reputation for reliability and excellence, making it the go-to choice for automotive companies seeking top-tier plastic injection mold companies.

Contribution to the Injection molding industry

Baoyuan's contribution to the Injection molding industry extends beyond its own success as an automotive injection molding company. By consistently pushing boundaries and introducing innovative solutions, Baoyuan has played a pivotal role in shaping the future of Plastic Injection Mold Companies worldwide. Through continuous research and development, Baoyuan is driving progress in plastic injection molding technology, setting new benchmarks for quality, efficiency, and sustainability.

Baoyuan's commitment to innovation and excellence has led to the development of cutting-edge technologies that have revolutionized the plastic injection molding industry. By investing in state-of-the-art equipment and employing top-notch engineers, Baoyuan has been able to enhance production processes, reduce waste, and improve overall product quality. This dedication to advancement has not only elevated Baoyuan's status within the industry but has also set a new standard for other companies to strive towards.

Conclusion

Achieving Business Success with Plastic Injection Mold Companies

In today's competitive market, businesses in the automotive industry must partner with reliable plastic injection molding companies to achieve success. With the advanced technology and cost-effective production processes offered by companies like Baoyuan, automotive manufacturers can streamline their operations and stay ahead of the competition. By collaborating with Baoyuan, automotive companies can benefit from their expertise in designing and manufacturing high-quality plastic components that meet industry standards and regulations. This partnership allows businesses to focus on their core competencies while relying on Baoyuan's specialized knowledge in plastic injection molding for the automotive sector.

Baoyuan's Commitment to Automotive Injection Molding Excellence

Baoyuan's dedication to excellence in automotive injection molding is evident in their efficient injection molding process, skilled team for mold design and production, and proficiency in quality assurance. With a keen eye on innovation, Baoyuan is constantly investing in cutting-edge technology and machinery to stay ahead of the curve in automotive plastic injection molding. This commitment to staying at the forefront of industry advancements ensures that Baoyuan can offer their clients the latest solutions and materials for their automotive components.

The Future of Automotive Plastic Injection Molding

As technology continues to advance, the future of automotive plastic injection molding looks promising. With ongoing innovation and expertise from companies like Baoyuan, we can expect to see even greater efficiency, customization options, and high-quality products in the automotive industry. One exciting development is the use of advanced materials in plastic injection molding, such as carbon fiber-reinforced polymers, which offer superior strength and lightweight properties. Additionally, the integration of smart manufacturing technologies will enable real-time monitoring and optimization of the injection molding process, leading to improved productivity and reduced waste. These advancements will not only benefit automakers but also consumers who can enjoy safer, more fuel-efficient vehicles with enhanced performance.